Understanding What Custom Metal Finishing Really Means

Custom metal finishing in Los Angeles isn’t just about making metal look good.It’s about transforming raw materials into durable, beautiful pieces that reflect both function and personality. From sleek furniture accents to high-end automotive components, finishing adds the final touch that separates ordinary from extraordinary.

If you’ve ever admired the mirror shine of a classic car bumper or the brushed texture on a modern art sculpture, you’ve already seen how finishing defines character. In Los Angeles, that creative flair blends perfectly with technical skill, producing results that are both stunning and enduring.

For first-time buyers, understanding what happens behind the scenes helps you appreciate the craftsmanship that goes into every piece of finished metal.

Why Los Angeles Is a Hub for Metal Finishing

Los Angeles has long been a city of creation. From architecture to automotive design, the region thrives on craftsmanship and precision. This creative energy extends into metal finishing, where local artisans and technicians combine technology with artistry to produce exceptional results.

Many local industries—film, aerospace, and luxury manufacturing—rely heavily on specialized finishes. That’s why so many workshops in LA have developed unique finishing processes tailored to these industries. It’s not unusual to find a craftsman here who treats metal finishing more like sculpture than production work.

To learn more about how surface treatments compare and which option might fit your project best, check out this guide on custom metal finishing in Los Angeles.

A Real-Life Look: My First Custom Metal Project

A few years back, I found an old steel coffee table at a flea market in Downtown LA. It was rusted, scratched, and covered in grime. But the bones were solid, and I could see its potential.

When I brought it to a local metal finishing shop, the technician walked me through several options—powder coating, plating, or a brushed finish. Each one completely changed the table’s look and durability. We decided on a brushed nickel finish.

Two weeks later, when I picked it up, I couldn’t believe the transformation. The dull, forgotten table now looked like something out of a designer catalog. That experience made me realize that finishing isn’t just a service—it’s an art form that brings life back into metal.

The Process: From Raw Metal to Finished Art

Custom metal finishing involves multiple precise steps, and every stage matters. Here’s how professionals in Los Angeles typically handle the process.

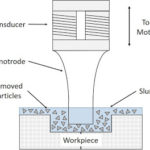

1. Surface Preparation

Before applying any finish, the metal is cleaned and smoothed to remove rust, oil, or dirt. This ensures the coating or plating adheres properly and lasts longer. LA’s eco-conscious shops often use non-toxic, water-based cleaning systems to reduce environmental impact.

2. Choosing the Right Technique

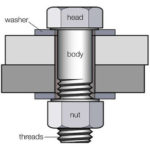

Once the surface is ready, the finisher selects a treatment based on the metal type and intended use. Common methods include electroplating, anodizing, polishing, and powder coating. Each one enhances different properties—some improve appearance, while others boost corrosion resistance or wear strength.

3. Application and Curing

The chosen finish is applied in controlled conditions, then cured or baked to ensure durability. In coastal areas like Los Angeles, where humidity can affect results, professionals carefully monitor this step to avoid oxidation or peeling.

4. Final Inspection

Every finished piece is inspected for texture, consistency, and color accuracy. This attention to detail ensures the product not only looks perfect but performs flawlessly too.

Choosing the Right Finish for Your Project

Selecting the right metal finish depends on both function and style.

If your piece will live outdoors, powder coating is a strong choice because it resists moisture and UV exposure.

For decorative or interior elements, brushed or satin finishes add elegance without high shine.

Meanwhile, plating—like nickel or chrome—offers unmatched protection for automotive or industrial applications.

A good finisher will help you balance beauty with practicality, so your piece performs well for years to come.

Technology and Innovation in Modern Metal Finishing

Los Angeles workshops have embraced cutting-edge technology to improve both precision and sustainability.

Computer-guided polishing systems, robotic arms, and automated coating chambers are now common in advanced facilities.

These tools ensure smoother finishes, tighter tolerances, and faster turnaround times.

But even with automation, the human touch remains irreplaceable. Skilled artisans still rely on instinct—knowing when to adjust pressure or timing based on how the metal “feels.” That balance of technology and craft is what gives LA’s metal finishing scene its edge.

Sustainability and Environmental Responsibility

With California’s strict environmental standards, Los Angeles finishers lead the charge in eco-friendly practices. Many have shifted to low-emission coatings, water recycling systems, and biodegradable cleaning agents. Customers today often ask about “green finishing” options, and reputable shops can easily accommodate those requests.

Eco-conscious finishing not only protects the planet but also results in cleaner, higher-quality surfaces with fewer chemical residues.

How to Find a Trustworthy Metal Finisher

For first-time buyers, finding the right professional can be the hardest part. Start by looking for shops that display clear portfolios of past work. Online reviews and word-of-mouth recommendations can reveal how a company treats its customers and projects.

Transparency is another key sign. The best shops explain every step of the process, including estimated time and cost.

If you can, visit the workshop. Seeing their setup firsthand tells you a lot about their professionalism and quality standards.

Common Mistakes to Avoid

- One of the biggest mistakes beginners make is focusing solely on aesthetics.

- A shiny surface doesn’t always mean long-lasting performance.

- Always consider where and how the metal will be used.

- Another mistake is neglecting proper maintenance after finishing.

- Even the toughest coatings need care to stay pristine.

Discuss these factors with your finisher early—it saves time, money, and potential disappointment later.

Understanding Costs and What Affects Pricing

Metal finishing prices in Los Angeles vary depending on the method, material, and complexity of the job.

Powder coating may be relatively affordable, while high-end plating or multi-layer treatments cost more.

Larger pieces and intricate designs also require more labor and precision.

Always request a detailed quote before starting. A reputable finisher will break down labor, materials, and additional costs so there are no surprises later.

Caring for Your Finished Piece

After your project is complete, maintenance becomes essential.

Most finishes can be cleaned with mild soap, water, and a soft cloth.

Avoid harsh abrasives or chemicals—they can strip coatings or dull the shine.

If your piece is exposed to moisture or sunlight regularly, consider reapplying a protective layer every few years.

A little upkeep goes a long way toward preserving its look and lifespan.

Final Thoughts: Crafting Beauty That Lasts

Custom metal finishing is more than a technical process—it’s where creativity, precision, and durability meet. In Los Angeles, that spirit of craftsmanship shines through every polished edge and brushed texture. Each project tells a story of transformation, from raw material to refined design.

For first-time buyers, the journey may seem intimidating at first. But once you see how your vision becomes tangible—how a dull piece of steel turns into a statement piece—you’ll understand why so many people fall in love with the process.

Metal finishing isn’t just about protection. It’s about pride, artistry, and the lasting impression that only well-crafted metal can make.