The Heartbeat of Every Pump System

AMT diaphragm parts are at the center of how diaphragm pumps deliver steady, uninterrupted performance. When you think about how water, chemicals, or slurry move through industrial systems, it’s these small yet critical components that make the magic happen.

They control pressure, maintain suction, and ensure smooth pumping without leaks or downtime. In a way, the diaphragm acts like the lungs of the pump—expanding and contracting rhythmically to keep the flow alive.

Anyone who’s ever worked with pumps knows that one tiny part failure can halt an entire operation. That’s why investing in durable, high-quality diaphragm components isn’t just smart—it’s essential for long-term reliability.

What Makes Diaphragm Pumps So Reliable

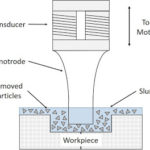

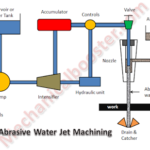

Unlike centrifugal or piston pumps, diaphragm pumps don’t rely on rotating seals or lubricated parts. Instead, they use a flexible diaphragm that moves back and forth to create suction. This design prevents fluid from ever touching the mechanical components, making it perfect for handling abrasive, corrosive, or viscous materials.

When I first started maintaining portable water systems for a construction site, I learned quickly that diaphragm pumps could take a beating. They handled mud, grit, and even small stones without missing a beat.

But when the diaphragm wore out after months of continuous use, performance dropped fast. That’s when I realized how critical it was to use genuine, well-fitted parts—not just any replacement that looked similar.

You can explore a range of AMT diaphragm parts specifically designed to ensure that level of reliability in challenging environments.

The Role of Materials and Design in Longevity

The material of the diaphragm makes or breaks the pump’s efficiency. Most modern diaphragms are made from rubber compounds like Buna-N, neoprene, or Viton, depending on the fluid being pumped. Each type has its own resistance level to chemicals, heat, and wear.

For example:

- Buna-N works well with petroleum-based fluids.

- Viton stands up to aggressive chemicals.

If you choose the wrong one, you could face rapid wear, cracking, or even failure within weeks. I’ve seen it firsthand—switching from a neoprene diaphragm to a chemical-resistant compound increased one unit’s life span by almost 40%.

The geometry of the part also matters. A well-engineered diaphragm moves smoothly with each stroke, distributing stress evenly. That prevents stretching or tearing, especially under heavy-duty loads.

Signs It’s Time to Replace Your Diaphragm Parts

Every pump gives off warning signs before failure—it’s just a matter of paying attention.

If you notice your flow rate dropping, pressure fluctuating, or strange noises during operation, your diaphragm might be wearing out. Sometimes the signs are subtle: a small drop in suction efficiency or fluid leaking around the housing.

In one irrigation project, I ignored a small pressure dip for weeks. When I finally opened the pump, the diaphragm was frayed and nearly split in half. Replacing it immediately restored full flow and saved the motor from overworking.

That experience taught me to treat diaphragm maintenance like changing car oil—routine, not optional.

Maintenance Tips That Keep Pumps Running Smooth

Regular inspection is your best line of defense.

- Check the diaphragm and valves every few months, especially in high-use systems.

- Clean any buildup or residue that might cause friction or uneven wear.

- Lubricating the moving components (where applicable) helps reduce stress, but avoid over-lubrication since most diaphragm pumps are designed to run dry.

- Always match your replacement parts to the original specifications.

Even a small deviation in thickness or flexibility can throw off the entire balance.

Why Proper Fit and Compatibility Matter

It’s tempting to grab the cheapest replacement that looks right, but diaphragm pumps are precision machines. A slightly undersized or misaligned part can reduce suction, create air leaks, or cause vibration.

I once tried fitting an off-brand diaphragm that claimed to be “universal.” Within days, the pump began losing prime, forcing me to stop operations mid-shift. The cost of downtime far exceeded what I saved on that part.

That’s why using correctly engineered components ensures proper sealing, alignment, and longevity. It’s not just about running—it’s about running efficiently.

Real-World Applications That Prove Their Value

From agriculture and wastewater management to construction dewatering, diaphragm pumps are everywhere.

- On a farm, they move fertilizers and pesticides with precision.

- In flood control operations, they handle slurry and debris that would destroy a standard pump.

During one flood-relief effort, I saw a diaphragm pump running nonstop for three days straight, clearing contaminated water without clogging once. Its performance depended entirely on the strength and elasticity of its diaphragm components.

That kind of reliability doesn’t happen by accident—it comes from engineering precision and routine maintenance.

Common Mistakes When Replacing Diaphragm Parts

- Mixing old and new components — Always replace all diaphragms and valves together for balanced performance.

- Ignoring pressure ratings — Overpressurizing can stretch the diaphragm and cause early failure.

- Using incompatible materials — Matching the diaphragm material to the fluid type prevents corrosion and swelling.

- Skipping gasket inspection — A worn gasket can cause leaks, even if the diaphragm is new.

Avoiding these mistakes can double your pump’s service life and minimize repair costs.

Environmental and Cost Benefits

Replacing worn parts instead of entire units reduces waste and saves money. It also cuts down on energy consumption since a pump with a healthy diaphragm doesn’t need to work as hard. That efficiency translates to lower operating costs and a smaller environmental footprint.

In some municipal projects, regular diaphragm replacement schedules have reduced total maintenance costs by 25% over two years. That’s not just sustainable—it’s smart business.

The Bottom Line

Reliable diaphragm pumps depend on the condition of their internal components. Every operator, from small contractors to industrial engineers, understands that downtime costs money. Choosing quality replacement parts isn’t a luxury—it’s insurance for performance and peace of mind.

Once you’ve seen how a properly maintained system runs—quietly, smoothly, and efficiently—it’s hard to settle for less. The difference is felt not just in output, but in confidence that your system will keep performing when it matters most.