CO2 Laser Mirrors: What are they used for?

Think of a time when you used a laser pointer to draw attention to something. Have you ever wondered how the beam of light stayed steady and strong even from a distance? It’s because of the use of mirrors. In the same way, CO2 laser mirrors are designed to handle the high energy of laser beams and reflect them with precision, making them a vital component in various fields of laser technology. This article will explore the different applications and benefits of CO2 laser mirrors and importance in laser technology.

What is a CO2 Laser Mirror?

CO2 laser mirrors are highly reflective mirrors made up of silicon or copper, that are used to direct and focus laser beams. They are unique from other mirrors because they can withstand the high energy levels of the CO2 laser and reflect the beam without distortion.

The curved surface of CO2 laser mirrors is highly polished to maximize reflectivity and beam precision. These mirrors are a critical component in laser technology. They allow for precise and accurate cutting, welding, engraving, and other applications.

Applications of CO2 Laser Mirrors

They have a wide range of applications, making them a vital component in laser technology.

Here are some of the most common uses :

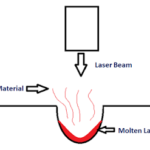

Industrial Cutting and Welding

CO2 laser mirrors are extensively used in the manufacturing and fabrication industry for cutting and welding applications. The laser beam is directed and focused by mirrors, allowing for precise cuts, smooth edges, and high-quality welds.

Medical Industry

CO2 lasers are used in medical fields to treat various conditions, such as skin resurfacing, cancer treatment, and even dental procedures. The high accuracy of CO2 laser mirrors enables surgeons to target specific areas with minimal damage to surrounding tissue. Pleiger Laseroptik is a one of the popular brands known to produce high-quality mirrors that provide accuracy and consistency in medical procedures.

Artistic and Decorative Works

CO2 laser mirrors are also used in artistic and decorative works to engrave, cut, or mark various materials, including wood, acrylic, and leather. The precision of the laser beam guided by mirrors allows for detailed designs and intricate patterns.

3D Printing

CO2 laser mirrors are used in 3D printing to fuse and melt the material layers together, creating a final product. The mirrors guide the laser beam to accurately melt and fuse the material, resulting in high-quality 3D prints.

Marking and Engraving

CO2 laser mirrors are used to create permanent and precise markings and engravings on various materials. The laser beam is directed by mirrors to engrave detailed designs or markings without the use of inks or chemicals.

Scientific Research

CO2 laser mirrors are used in scientific research for spectroscopy and laser-based experiments. The mirrors are used to guide and direct the laser beam, allowing for accurate and reliable results.

Also Read:

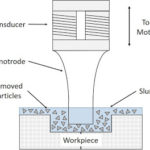

- What is Electrical Discharge Machining (EDM) Process and How it Works?

- What is Electron Beam Machining – Parts, Working, Advantages, Disadvantages with Application

- What is Slotter Machine – Parts, Types, Working, Operations, Advantages and Disadvantages?

Types of CO2 Laser Mirrors

The type of mirror used in a CO2 laser system will depend on its intended application and the requirements of the laser cavity.

Here are common ones:

Total Reflectors: Reflect all the light back into the laser cavity and are typically made of a gold-coated copper substrate with a reflectivity of around 99.8%.

Output Couplers: Extract a portion of the laser beam to create the output beam and have a reflectivity of around 95-98%. Usually made of a partially reflective dielectric coating on a substrate material such as copper or silicon.

Folding Mirrors: Reflect the laser beam at a 90-degree angle to change the direction of the beam within the cavity. Made with the same materials as total reflectors and output couplers.

Turning Mirrors: Reflect the laser beam at an angle to change the direction of the beam within the cavity. Often made of a dielectric coating on a substrate material such as silicon or fused silica.

Steering Mirrors: Steer the beam to a particular location outside the cavity and are often made of a dielectric coating on a substrate material such as silicon or fused silica.

Advantages of CO2 Laser Mirrors

There are numerous advantages to using CO2 laser mirrors in laser technology. Here are some of the benefits of using CO2 laser mirrors:

Precision

CO2 laser mirrors allow for highly accurate and precise beam guidance, resulting in high-quality cuts, engravings, and welds. The mirrors’ curved and highly polished surfaces maximize reflectivity, ensuring the laser beam’s accuracy and precision.

Durability

They are made up of high-quality materials such as copper or silicon, making them highly durable and resistant to high energy levels. They can withstand the high temperatures and pressures of laser technology, ensuring long-lasting and reliable performance.

Efficiency

CO2 laser mirrors allow for the efficient use of laser energy, reducing the amount of energy needed to achieve the desired results. This results in lower operating costs and reduced environmental impact.

Versatility

They can be used in a wide range of applications, making them highly versatile. They can be used in the medical field, manufacturing, artistic works, and scientific research, among others.

Low Maintenance

It requires minimal maintenance, making them highly cost-effective in the long run. They have a long lifespan and can operate reliably for extended periods without the need for frequent maintenance.

Conclusion

CO2 laser mirrors provide highly precise and accurate beam guidance, ensuring high-quality results in various fields like medicine, manufacturing, and artistic. As technology advances, CO2 laser mirrors will continue to play a critical role in various fields, providing a reliable and efficient solution to complex challenges.