Introduction

A blast furnace is a special type of cylindrical furnace, which is basically used for the purpose of smelting. So, the industrial metals can be extracted from their ores like iron, pig iron, or copper.

The word ‘blast’ gives the idea of combustion air which is forcefully supplied or produced to the atmospheric pressure above. In past times, furnaces were used to produce only iron by using charcoal.

Soon after the shortage of wood because of deforestation, coal was suggested to be used for the purpose. Since coal contains Sulphur which makes iron quiet brittle, it was assumed to be wastage for the iron life.

However, in 17th century Abraham Darby accomplished his mission to produce such furnace which can be used for smelting iron using coke as fuel. His achievement was marvellous which increased the trade of iron and finally lead to the Industrial Revolution.

This article comprehensively discusses and elaborates the information regarding blast furnace, its construction details, including its main parts and their working phenomenon and function. This article also highlights the application of these furnaces for its practical use.

Definition of Blast Furnace:

It is defined as a metallurgical furnace which is used to extract metals primarily from its ores of iron and copper. The fuel contains a mixture of flux that is particularly limestone where iron ore is available, and coke is supplied and pumped through the top of the furnace.

On the other hand, the bottom of the furnace is attached with a series of parallel pipes that transfer hot blast air which is enriched with oxygen.

As soon as the hot air is allowed to enter, the oxide ore is reduced to convert it into impure metal. As both the material is mixed, the chemical reaction takes place causing the molten metal to fall down where it is tapped off and collected.

The waste of the material which is basically ‘slag’ goes at the top of the furnace where it is piped off. The molten metal and this slag are the end products of this procedure. These flow of both the products in opposite directions along with different combustion gases are termed as countercurrent exchange.

However, there are similar procedures used for various purposes including blowing houses to obtain tin, lead and can be extracted by smelting mills and similarly, iron is obtained by bloomer furnace. These all are classified as blast furnaces.

Nevertheless, this term is used for a very limited purpose as for smelting iron ore. This smelting would help for the production of pig iron, which is a majorly used material in the processing of iron and steel production.

Section of Blast Furnace:

A Blast Furnace is consist of the following sections:

- Furnace Proper

- Cast House

- Stoves

- Raw Material Storage Section

- Raw Material Charging Section

- Gas Cleaning Point

- Slag Dumping Area

- Pulverised coal Inoculation

So let me discuss 1 by 1.

Furnace Proper:

It is the total furnace area where we inject the hot metal with the slag which is generated from the raw material.

Cast House:

In the cast house, hot metal with slag flowing through a channel where it is divided into two forms, one is hot metal and another one is slag and then further going to the iron and slag side sequentially of the Furnace.

Stoves:

Stoves are used to heat the air which is provided by the high-speed blower.

Raw Material Storage Section:

In this section raw material are stored, it designed so carefully that raw material can easily be transferred from this section.

Raw Material Charging Section:

As the name denotes it is a charging station. Here in this section, we can see a hopper through which the raw material enters the furnace.

Gas Cleaning Point:

As we use several types of fuel to generate the heat, in this scenario also there is a lot of burned gas is generated inside the blast furnace, so we need to have point or section, from which we can easily extract the burned gases.

Slag Dumping Area:

In a blast furnace, while the process of extracting the iron has occurred at that time, we also get slag or impurities. To remove this we use two types of method.

One is using of a high-pressure water jet, which blends with the slag or impurities then we send the mixture to the granulation plan, secondly if it is unable to granulate in the granulation plant then we make a separate area where we dumped the slag.

Pulverised coal Inoculation:

In this section, we charge the crushed coal dust so that it can easily take the fire.

Also Read:

- What is Forging ? – Complete Explanation

- What is Cast Iron? Complete Explanation

- What is Induction Heating?

Main Parts of Blast Furnace:

A blast consisted of the following parts:

- Hoppers

- Adjustable Gates

- Rotating Chute

- Fire brick

- Combustion

- Gas burner

- Carbon brick

- Taphole

- Tuyere

Hopper:

It is a cone-shaped funnel which is used for pouring the raw material which comes from the raw material storage section.

Adjustable Gates:

To control the flow and quantity of the raw material we need to use the adjustable gate. It can be controlled manually, however, in modern blast furnaces it is opened or closed electronically.

Rotating Chute:

It is used to blend the raw materials and more importantly, it prevents the escape of furnace gas while charging the raw materials.

Fire brick:

Fire clay bricks are used to protect the furnace shell. It is made of ceramic material, it can withstand high temperature and its thermal conductivity is very low.

Combustion Chamber:

It is a chamber where the combustion of the fuel occurred.

Gas Burner:

To generate the fire we need a burner, so inside the combustion chamber, a gas burner is fitted.

Carbon Brick:

The outside of the combustion chamber is made by Carbon brick because it has more capability to resist the withstand the internal heat of the combustion chamber. It is a composite refractory material, with more slag resistance capability and high thermal conductivity and low expansibility of carbon.

Taphole:

Through the tap hole, we can draw the molten material outside the furnace.

Tuyere:

It is a pipe, by which we supply the air to the furnace. To generate the air we can use high-pressure blowers.

Zones of Blast Furnace:

In the blast furnace, we can see there are four main zones.

- Stack

- Barrel

- Bosh

- Hearth

Stack Zone:

It is the top zone of a Blast furnace, covered by Fire Brick. In this section hot gases rise from the combustion chamber and flow upwards to heat the newly come raw material from the hoppers.

Barrel Zone:

It comparatively more heated on then stack. It is also called a reduction zone, where chemical relations have occurred.

Bosh Zone:

It is an intermediate zone between Heart (Bottom) and Bosh. It is the hottest part of the furnace because in this section the proximity to the reaction between air and coke is very close. Some portion of bosh is covered by thick fire clay bricks and some portion is covered by carbon brick.

Hearth Zone:

It is the bottom portion of the blast furnace. In heart zone, hot gases are coming from one side and fresh atmospheric gases come from the other side through the Tuyere.

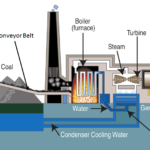

Construction Details of Blast Furnace:

The blast furnace is constructed in the form of a tall structure, placed with special kind of bricks (Fire Clay bricks) which are resistant to decomposition by any of the environmental attacks. These bricks are the outlines to enable the expansion of charged materials.

As soon as melting starts to occur, these brick heat and reduces in size. The complete procedure is built with the help of various materials and compartments to start processing. These include Hot blast from Cowper stoves, exhaust gases, reduction zone of ferric oxide (stack), a long column containing ore, limestone, and coke, pre-heating zone, melting zone (bosh), reduction zone of ferrous oxide (barrel) and feed of ore, coke, and limestone. These components have different features and purposes, which are discussed later in the article.

The detailed construction of blast furnace is categorized into two zones which are physical zones and chemical zones. In the physical zone, the structural system of this blast furnace is divided into five sections that include bosh, shaft, belly, hearth, and tuyeres.

On the other hand, the chemical zone is also subdivided into five regions which are stack zone, cohesive or softening zone, active coke zone, raceway (or tuyere) zone, and hearth zone.

Also Read:

- What is Lathe Machine? Main parts, Operations and Working

- What is Slotter Machine?

- What is Shaper Machine?

Working Procedure of Blast Furnace:

The working phenomenon of this blast furnace is very simple. In order to smelt iron from its ores, first of all, limestone flux, coke, and iron ore are introduced into the top face of the furnace. They are allowed to enter with very precision order so that gas flow and other chemical reactions can be controlled effectively.

The gas which is very hot and dirty is pressurized and supplied to exit point of the furnace through its throat whereas ‘bleeder valves’ helps protect the sudden gas pressure exerted at the top of the furnace.

The exhaust gas contains coarse particles that are deposited in the ‘dust catcher’ so that they can be disposed of. On the other hand, a ‘venturi scrubber’ is provided to flow the gas through it and later the gas passes from the gas cooler for the purpose of decreasing the temperature of the cleaned gas.

The bottom half of the furnace possesses water cooler copper tuyeres, bustle pipe and the equipment to collect slag and liquid iron. This compartment is generally termed as ‘cast house’.

A tap is inserted in the refractory clay plug so that to make the flow of the liquid iron and slag through a ‘skimmer’ which spates iron and slag. The advanced giant blast furnaces usually have four tap holes and two cast houses. As soon as the slag and pig iron is collected, the refractory clay is freed from the tap hole.

Application of Blast Furnace:

- There are numerous applications of blast furnaces that are being practiced in various big as well as small industries mostly.

- In general, it is used to produce Pig iron from its ore.

- It is used in process plants.

- The slag of the blast furnace has hydraulic properties which are used in cement as a additives

- Slag also helps in soil stabilization.

Advantages of Blast Furnace:

The blast furnaces help to save fuel from 82 to 87 MJ/t-HM which are installed in the industries. In Japan, it was observed that around 0.125 GJ/t-pig iron has been saved in a 1 Mt/y by only recovering 50% of the stove flue gases.

Hot blast stoves are generally used to recuperate heat which helps to reduce energy demand by 0.26 GJ/t-HM and globally, it is used to decrease the energy potential by 0.15 EJ/y. whereas, it is assumed that maximum energy that can be saved is about 0.3 GJ/t-pig iron.

Furthermore, the coke rate and tuyere level injections are reduced by using the increased top pressure of about 0.6 Bar Gauge in the blast furnace. These high pressurized furnaces help to produce electricity around 0.35 GJ/t-HM provided that the recovery turbines are installed.

Similarly, coke consumption is feasible by using blast furnaces by 26% of coke saving/ton. For this, blast furnace having a top gas recycling service will be preferred. While on the other hand, if this furnace is combined with dry de-dusting gas, then it will reduce water consumption by 9 Nm3/tH and increase the power generation system by 30%.

Moreover, if blast furnace is used with biomass, PCI can be substituted fully by charcoal which will be merely 45% of the carbon input. When blast furnace gases are released they are improved and recovered which also helps in saving energy by 35% MJ/t-HM to 70% MJ/t-HM. Hence, the total, energy-saving amount which is made possible by these blast furnace procedures is of about 0.4 GJ/t-HM.

So this is the complete explanation of Blast Furnace I hope you liked this article, if so then do share this paper with your friends and if you have any doubts, feel free to comment down below.