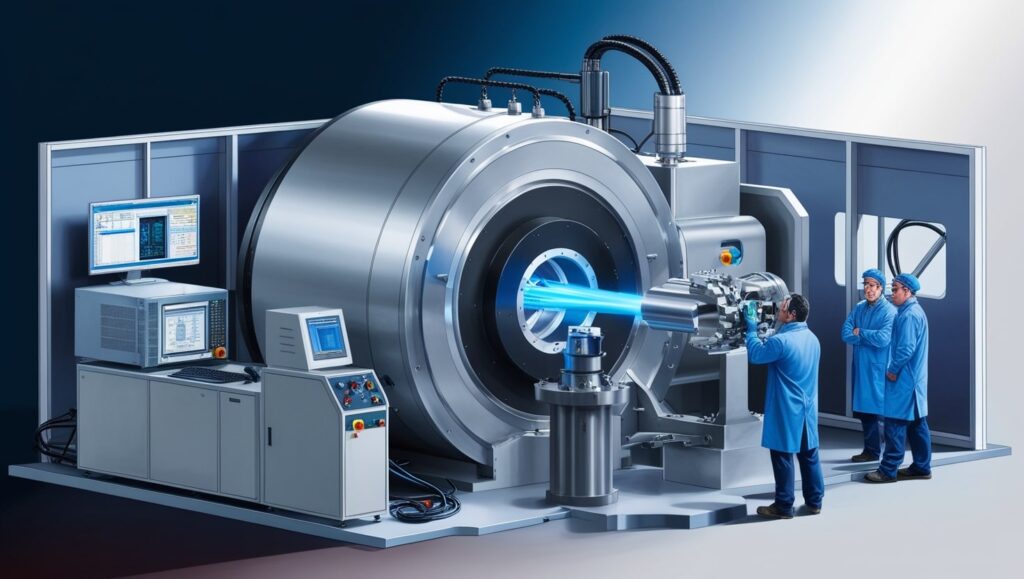

Electron Beam Machining (EBM) is an advanced manufacturing process used to create precise cuts, holes, and shapes in materials. It uses a concentrated beam of electrons to melt or vaporize material, allowing for incredibly accurate machining. In this blog post, we’ll break down what electron beam machining is, how it works, and why it’s important.

What is Electron Beam Machining?

Electron Beam Machining, or EBM, is a non-contact machining process. This means that the tool (the electron beam) doesn’t physically touch the material it’s working on. Instead, it uses a high-energy beam of electrons that are focused onto a small area of the material. The energy from the electrons generates heat, which melts or vaporizes the material to achieve the desired cut or shape.

Construction of Electron Beam Machining

The EBM machine has several critical components, each playing a vital role in the machining process. Let’s explore its main parts and their functions:

1. Electron Gun

- Function: Generates the high-speed electron beam used for machining.

- How it Works: A cathode made of tungsten or tantalum is heated to produce electrons through thermionic emission.

2. Anode

- Function: Accelerates the electrons emitted by the cathode.

- How it Works: The anode, placed at a positive potential, draws the electrons toward itself, accelerating them to very high speeds.

3. Focusing Lens (Magnetic Lenses)

- Function: Focuses the high-energy electron beam into a narrow, precise stream.

- How it Works: Magnetic fields generated by coils align and concentrate the electron beam.

4. Deflection Coils

- Function: Directs and positions the electron beam onto the desired area of the workpiece.

- How it Works: Magnetic fields adjust the beam’s path to precisely target specific points.

5. Workpiece Table

- Function: Holds the material to be machined.

- Features: The table can be adjusted to different positions to ensure precise machining of the workpiece.

6. Vacuum Chamber

- Function: Maintains a vacuum environment to prevent electron scattering.

- How it Works: Removes air and contaminants that could disrupt the electron beam’s focus.

7. Power Supply

- Function: Provides the necessary electrical energy to the electron gun, anode, and other components.

How Does Electron Beam Machining Work?

The process involves several key steps:

- Electron Beam Generation:

An electron gun produces a stream of electrons by heating a cathode (a negatively charged electrode). These electrons are accelerated to high speeds using an electric field. - Beam Focusing and Directing:

Magnetic lenses focus the electron beam into a narrow, precise stream. This focused beam is directed onto the workpiece. - Material Removal:

When the high-energy electron beam hits the surface of the material, it generates intense heat. This heat is enough to melt or vaporize the material, removing it in the desired pattern. - Vacuum Chamber:

EBM takes place inside a vacuum chamber. This prevents the electrons from scattering and ensures a highly focused and efficient beam.

Also Read:

- What is Laser Beam Machining – Main Parts, Principle, Working with Application

- What is Plasma Arc Machining (PAM) And How it Works?

- What is Electron Beam Welding? – Complete Explanation

Advantages of Electron Beam Machining

- High Precision:

EBM can create extremely small, detailed features with tolerances as tight as a few micrometers. - Works on Tough Materials:

It can machine hard and heat-resistant materials like titanium and tungsten, which are difficult to cut using traditional methods. - No Tool Wear:

Since the process is non-contact, there’s no physical wear and tear on tools, reducing maintenance costs. - Clean and Smooth Cuts:

The focused energy of the electron beam results in minimal material deformation and leaves smooth, precise edges.

Applications of Electron Beam Machining

Electron Beam Machining is widely used in industries where precision is crucial. Here are some common applications:

- Aerospace Industry: For creating precise components like turbine blades and jet engine parts.

- Medical Field: In the production of implants and surgical instruments.

- Electronics: For micromachining circuits and delicate components.

- Automotive Industry: In manufacturing high-strength parts.

Limitations of Electron Beam Machining

While EBM is an advanced technology, it does have some limitations:

- High Cost: The equipment and vacuum chambers required are expensive.

- Slow Processing: It is not ideal for high-volume production as it works on small areas at a time.

- Material Restrictions: Conductive materials are more suitable for this process; non-conductive materials are challenging to machine.

Why Choose Electron Beam Machining?

If your project requires high precision and involves tough materials, EBM is one of the best machining methods available. Its ability to work on complex designs and deliver clean, detailed results makes it a valuable tool in industries like aerospace, electronics, and medicine.

Conclusion

Electron Beam Machining is a fascinating technology that showcases the power of electron beams in advanced manufacturing. By using focused energy, it delivers unparalleled precision and works on some of the toughest materials. While it may have limitations, its advantages make it indispensable in industries requiring high accuracy.

If you’re looking to learn more about machining technologies, stay tuned to our blog for more beginner-friendly guides!

Multiple Choice Questions on Electron Beam Machining (EBM)

1. What is the primary energy source used in Electron Beam Machining?

a) Light beam

b) Laser beam

c) Electron beam

d) Plasma arc

2. Why is a vacuum chamber necessary in Electron Beam Machining?

a) To cool down the workpiece

b) To prevent scattering of the electron beam

c) To remove unwanted material

d) To focus the magnetic lens

3. Which component generates the electrons in the EBM process?

a) Anode

b) Cathode

c) Deflection coil

d) Power supply

4. What material is commonly used for the cathode in EBM?

a) Copper

b) Steel

c) Tungsten

d) Aluminum

5. What is the role of magnetic lenses in Electron Beam Machining?

a) Generate electrons

b) Focus the electron beam

c) Accelerate the electrons

d) Remove material from the workpiece

6. In which industry is Electron Beam Machining commonly used?

a) Food industry

b) Textile industry

c) Aerospace industry

d) Agriculture industry

7. What type of materials are most suitable for machining using EBM?

a) Non-conductive materials

b) Soft materials

c) Hard and heat-resistant materials

d) Plastic materials

8. Which of the following is NOT an advantage of Electron Beam Machining?

a) High precision

b) No tool wear

c) High processing speed for large areas

d) Clean and smooth cuts

9. What is the main function of the deflection coil in EBM?

a) Generate heat on the workpiece

b) Direct the electron beam to the desired location

c) Maintain the vacuum environment

d) Accelerate the electron beam

10. What happens to the material when the electron beam hits the workpiece?

a) It melts or vaporizes

b) It solidifies

c) It cools down instantly

d) It changes color

Answers

- c) Electron beam

- b) To prevent scattering of the electron beam

- b) Cathode

- c) Tungsten

- b) Focus the electron beam

- c) Aerospace industry

- c) Hard and heat-resistant materials

- c) High processing speed for large areas

- b) Direct the electron beam to the desired location

- a) It melts or vaporizes