It is a joining process of metals and thermoplastics with the help of high heat that melts the metals and fuses them together to form a strong weld joint on cooling. Pressure is also applied in some cases to make the metals fuse together during the cooling of the weld. In some cases, Filler metal is used for joining the metal pieces together. Unlike brazing and soldering in which the base metal is not melted, the base metal melts in the welding process.

For performing the welding process we have several welding equipment that help in the joining process.

Various welding equipment are

- Welding Machine

- Welding electrodes

- Filler metals

- Electrode holder

Safety Equipment that is very essential for the safe working are

- Welding Helmet

- Welding apron or Jacket

- Welding Gloves

- Safety Glasses

- Mask or Respirator

- Earplugs

- Shoes

Types of Welding

Welding can be classified mainly into 5 types and these are:

1. Arc Welding

2. Gas Welding

3. Resistance Welding

4. Energy Beam Welding

5. Solid-state Welding

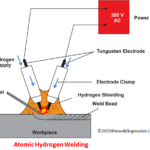

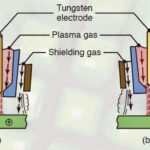

1. Arc Welding

The process of joining two or more metal pieces together with the help electric arc is called arc welding. The arc is produced by electrical power supply. Direct current (DC) or alternating current (AC) can be used in arc welding to produce an arc. The electrode used in this welding types may consumable or non-consumable. Shield gas is used to protect the welding region from contamination from the atmosphere. The type of shielding gas used may inert or semi inert. A filler material is also used some time for welding two pieces together.

The various types of arc welding are:

1. Shielded metal arc Welding (SMAW)

2. Gas metal arc welding (GMAW), metal inert gas or MIG welding

3. Flux-cored arc welding (FCAW)

4. Gas Tungsten arc welding (GTAW): Tungsten inert gas (TIG) welding

5. Submerged arc welding (SAW)

6. Atomic hydrogen welding

7. electroslag welding (ESW)

8. Electrogas welding

9. Stud arc welding

10. Plasma arc welding (PAW)

11. Carbon arc welding (CAW)

2. Gas Welding

It is the oldest welding process in which acetylene gas is burnt in the presence of oxygen to give a flame that can produce a welding temperature of about 3100 degrees Celsius.

- It is also called as oxyfuel welding or oxyacetylene welding.

- Its equipment is simple and not much expensive.The arc produced in this welding is less concentrated as compared with arc welding and this can lead to slower cooling of weld which reuslts higer residual stresses and distortion.

- It less popular process in industrial works and widely used in welding pipes, tubes and in repair works.

Also Read:

- What is Plasma Arc Machining (PAM) And How it Works?

- Ultrasonic Machining (USM) – Main Parts, Working Principle, Advantages and Disadvantages with Application

- What is Electrical Discharge Machining (EDM) Process and How it Works?

3. Resistance Welding

It is a welding technique in which electric current is used to join two metal pieces together. The Resistance of material is used to generate heat at the joints to be weld.A current value ranging from 100 A to 100,000 is passed through the metals that are to be joined.In this compressive froces is also used to join the pieces during the welding process.

- This welding is widely used in the manufacturing of steel pipes and in automobiles to weld assembly of vehicles.

- A Very less pollution is caused in the process and is an efficient process.

- The only limitations of resistance welding is that is can be used to weld only thin metal pieces.

The types of resistance welding that is most commonly used are

1. Spot Welding

2. Seam welding

3. Butt Welding

4. Flash Welding

5. Projection welding

6. Upset Welding

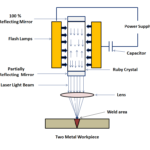

4. Energy Beam Welding

In this welding methods, a high energy beam is used to stike on the region to be welded. These welding methods include laser beam beam welding and electron beam welding.

Both the welding is nearly similar but if notice carefully they are differ in their source of energy. In laser beam welding, a very highly focused beam of laser is used for the heat generation to make joint and in Electron beam welding, a very high density electron beam is used. EBW is done is vacuum. They are used in high production applications.

Advantages

- the energy density of these welding methods is very high.

- It produces very deep weld penetration and reduces the size of the weld area.

- they can be automated easily for large production.

Disadvantages

- High equipment cost.

The types of welding methods are

1. Laser beam welding

2. Electron beam welding

5. Solid-State Welding

In solid-state welding, the two metal or plastic pieces that are joined together without melting i.e. the joint are formed in solid-state. for example, Ultrasonic welding in which the two metal pieces are welded together by using very high-frequency vibration under high pressure.

The types of solid-state welding are:

1. Ultrasonic welding

2. Explosive welding

3. Friction welding

4. Friction stir welding

5. Magnetic pulse welding

6. Cold welding

7. Diffusion bonding

8. Exothermic welding/ Thermite Welding

9. high-frequency welding

10. Hot Pressure welding

11. Induction welding

12. Roll Bonding

In this article, we have learned about what is welding its main types in brief. If you found this piece of information valuable and useful then don’t forget to like and share it.

References: