Introduction

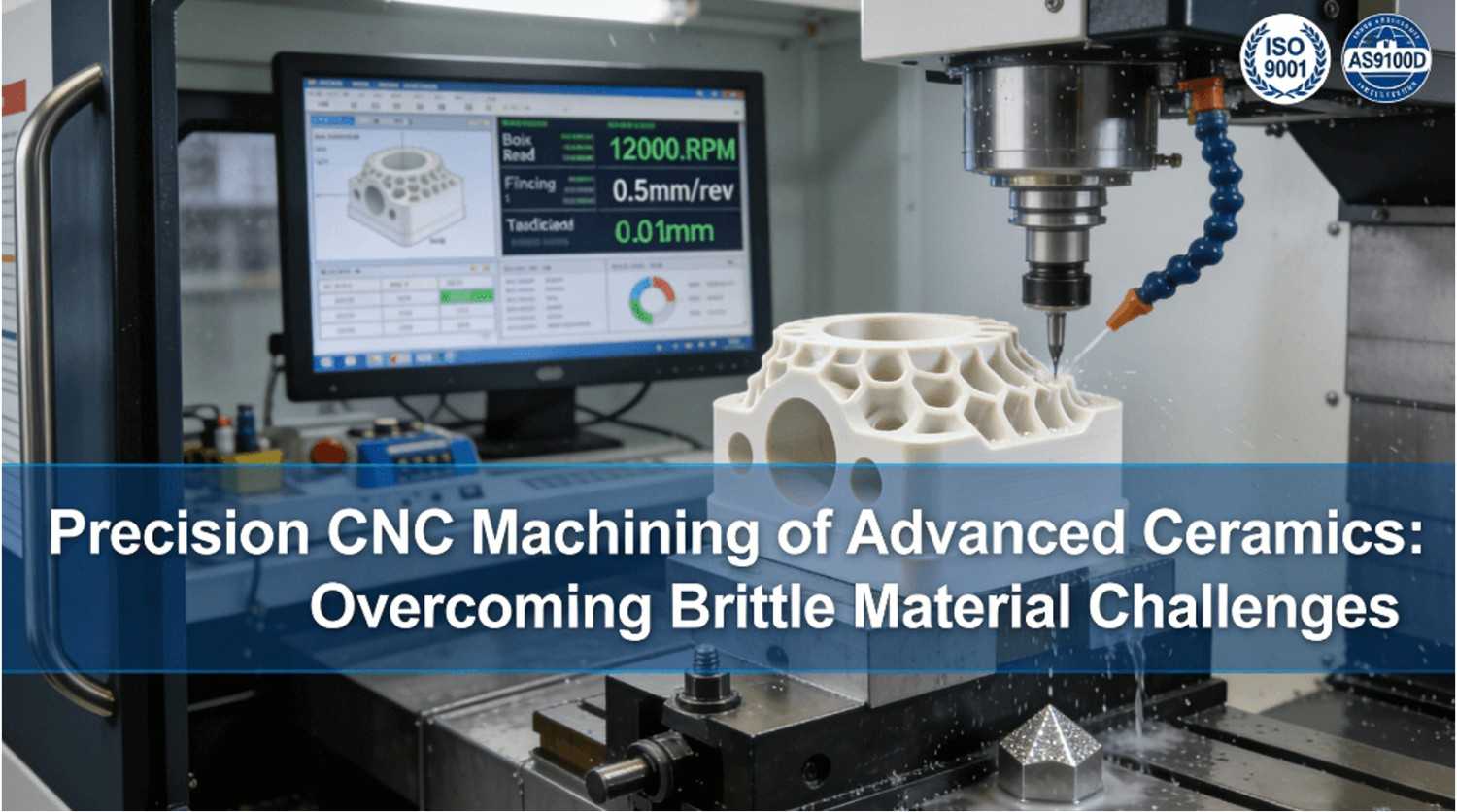

Advanced ceramic materials like alumina and silicon nitride are prized in aerospace and medical industries for their exceptional hardness and high-temperature resistance. However, their inherent brittleness and extreme hardness make them notoriously difficult to machine, often resulting in micro-cracks, edge chipping, and sub-surface damage that compromise component reliability and lifespan.

The root cause is the fundamental difference in material behavior; unlike ductile metals, ceramics fail through brittle fracture. This guide explains how specialized Ceramic CNC Machining Process techniques overcome these challenges through digital precision and optimized strategies. First, we must explore the specific bottlenecks created by ceramic’s unique properties.

What Are the Unique Challenges in Machining Brittle Materials Like Advanced Ceramics?

Machining advanced ceramics requires a paradigm shift from standard metalworking. The primary challenges stem directly from their material science, demanding a highly controlled approach to avoid catastrophic failure at the micro-scale.

The Dominance of Brittle Fracture Over Plastic Deformation

The core difference between machining metals and ceramics is the material removal mechanism. Metals are cut via plastic deformation and chip formation. In contrast, ceramics lack significant ductility; material is removed through brittle fracture and micro-cracking. If not meticulously managed, these micro-cracks can propagate deep into the workpiece, creating latent flaws that lead to premature part failure under load. Controlling this fracture mechanism is the fundamental challenge.

Extreme Hardness and Rapid Tool Wear

The exceptional hardness of advanced ceramics, which makes them wear-resistant in application, is a major obstacle during machining. It causes extremely rapid tool wear when using conventional carbide or high-speed steel tools. This necessitates the use of ultra-hard tooling, most commonly polycrystalline diamond (PCD) implements. The durability of these specialized tools under harsh machining conditions is critical, and their performance can be validated through standardized tests, such as those outlined in ASTM B117 Standard practice for operating salt spray (fog) apparatus, which can assess the impact of coolants on tool life.

Stress Concentration and Edge Integrity

The geometric features of a part, such as sharp internal corners or thin walls, act as stress concentrators during machining. The cutting forces can easily exceed the local tensile strength of the ceramic, leading to edge chipping or spalling. This makes achieving sharp, pristine edges one of the most difficult aspects of the process, requiring sophisticated tool path programming and fixturing to minimize stress at these critical locations.

How Does the Ceramic CNC Machining Process Effectively Overcome These Limitations?

Specialized CNC machining transforms the challenging nature of ceramics into a manageable and precise manufacturing method. It does so by implementing a suite of targeted strategies designed to suppress brittle fracture and promote a more controlled, ductile-regime material removal.

- “Ductile-Regime” Machining and Micron-Level Control: The most significant advancement is the application of ductile-regime machining. By using very small depth of cuts (often in the micron range) and high spindle speeds, the material is subjected to stresses high enough for removal but below the threshold for brittle fracture. This promotes a plastic deformation mechanism similar to metals, resulting in a smooth, damage-free surface. This precision control is the cornerstone of producing high-integrity ceramic components.

- The Critical Role of Multi-Axis CNC and Rigid Setups: Achieving ductile-regime machining demands exceptional machine tool stability and rigidity. High-precision, multi-axis CNC machines provide the dynamic control and lack of vibration necessary to maintain consistent, tiny chip loads. The ability to manipulate the part in multiple axes allows the tool to engage the workpiece at optimal angles, maintaining constant cutting conditions and further preventing chatter and stress spikes that lead to cracking.

- Specialized Tooling and Optimized Coolant Strategies: The choice of tooling is non-negotiable. Diamond-impregnated tools, such as electroplated or vitrified diamond grinding wheels, are standard. Their extreme hardness withstands the abrasiveness of ceramics. Coupled with this, precise coolant application is vital. The coolant manages the high heat generated, reduces friction, and efficiently evacuates abrasive particles, protecting both the tool and the workpiece surface. To achieve this level of process control, a deep understanding of ceramic CNC machining parameters is essential, as explored in-depth in specialized technical guides.

What Are the Key Advantages of Using CNC Machining for High-Performance Ceramic Components?

Beyond simply making a part, CNC machining enables ceramic components to achieve their full potential, offering distinct advantages that other manufacturing methods cannot match.

1. Unmatched Geometric Freedom and Design Complexity

CNC machining provides exceptional geometric freedom, allowing for the production of complex 3D contours, intricate internal channels, and delicate thin-walled structures that are impossible with traditional grinding or pressing methods. This enables designers to optimize parts for function without being constrained by manufacturing limitations, unlocking new possibilities in component design and performance.

2. Superior Dimensional Accuracy and Surface Integrity

The digital nature of CNC processes ensures exceptional dimensional accuracy,holding tolerances in the single-digit micron range. Furthermore, the process can produce superior surface finishes with very low roughness (Ra), often eliminating the need for secondary polishing. This level of precision is critical for applications like seals, bearings, and optical components.

3. Preservation of Material Properties and Batch Consistency

Perhaps the most critical advantage is the preservation of inherent material properties. By minimizing sub-surface damage, the ceramic part’s high strength, wear resistance, and corrosion resistance are fully retained. Furthermore, the digital process ensures batch consistency, guaranteeing that every produced part, from prototype to production run, meets the same high-quality standard. This commitment to consistency is a fundamental requirement for manufacturers operating under ISO 9001 and AS9100D certifications, ensuring every step from prototyping to full production is controlled.

Where Are CNC-Machined Ceramics Making a Critical Impact Across Industries?

The ability to reliably produce high-precision ceramic components is driving innovation across multiple high-tech sectors, where performance and reliability are paramount.

- Aerospace and Defense Applications: In aerospace, machined advanced ceramics are used for high-temperature components like turbine engine vanes, insulating rings, and radomes. Their ability to maintain strength and dimensional stability at extreme temperatures is crucial for efficiency and safety. The precision afforded by CNC machining ensures these critical parts meet stringent performance specifications.

- Medical Device and Life Sciences Innovation: The biocompatibility and wear resistance of ceramics like zirconia make them ideal for medical implants such as femoral heads for hip replacements and dental implants. CNC machining achieves the required mirror-like surface finish for low friction and biocompatibility, along with the complex geometries needed for osseointegration and custom-fit devices.

- Semiconductor and Advanced Industrial Manufacturing: The semiconductor industry relies on high-purity alumina and silicon carbide for components like wafer chucks and plasma etch parts. These applications demand exceptional flatness, purity, and resistance to corrosive plasmas. CNC machining meets these rigorous requirements, enabling the production of components that are fundamental to the fabrication of microchips.

What Factors Influence the Success and Cost of a Ceramic Machining Project?

Understanding the key cost and feasibility drivers helps in effectively planning a ceramic machining project and setting realistic expectations for budget and timeline.

1. Material Selection and Part Geometry Complexity

The specific type of advanced ceramic chosen significantly impacts machinability and cost. For instance, silicon nitride is tougher but more expensive to machine than alumina. Furthermore, part geometric complexity is a major cost driver. Deep holes, high aspect ratios, and intricate features require more sophisticated programming, longer machining times, and specialized fixturing, increasing the overall project cost.

2. Precision Tolerances and Surface Finish Requirements

The required dimensional and geometric tolerances have an exponential effect on cost. Holding a tolerance of ±0.01 mm is significantly more involved and time-consuming than ±0.05 mm. Similarly, achieving a specific surface roughness (e.g., Ra < 0.2 µm) may require additional finishing steps. Adhering to precision measurement standard defined by organizations like National Institute of Standards and Technology (NIST) is the foundation of high-end manufacturing, ensuring every dimension meets specification.

3. Quality Assurance and Regulatory Compliance Needs

The level of quality assurance and need for industry-specific certifications directly influence project cost. Projects requiring full traceability, extensive CMM inspection reports, and compliance with standards like IATF 16949 (automotive) or AS9100D (aerospace) necessitate rigorous documentation and validated processes, which adds value and cost. Partnering with a supplier experienced in these protocols is essential for mission-critical applications.

Conclusion

CNC machining services has revolutionized the manufacturing landscape for high-performance ceramic components. By understanding and applying the specialized principles of ductile-regime machining, precise toolpath control, and rigorous process management, manufacturers can overcome the inherent challenges of ceramic materials. This transforms their exceptional theoretical properties into reliable, high-performing end-use products, thereby fueling innovation across aerospace, medical, and industrial sectors.

FAQs

A: The primary reason is extreme hardness and abrasiveness, causing rapid tool wear and necessitating expensive diamond tools. The process also requires slower removal rates and meticulous programming, increasing cost but delivering high-reliability components.

A: Yes, with expert process control. Optimizing clamping strategies and using techniques like “peck” milling can produce thin walls down to 0.2mm. Success hinges on managing brittle fracture through precise force control.

A: Key points include avoiding sharp internal corners, maintaining uniform wall thickness, and setting realistic tolerances. An early Design for Manufacturability (DFM) review is the most effective step for optimization.

A: A superior surface finish reduces friction, improves corrosion resistance by eliminating micro-crack sites, and is essential for biocompatibility. CNC can achieve very low roughness values, critical for performance.

A: For critical applications, industry-specific certifications are paramount. ISO 9001 is foundational, while AS9100D (aerospace), IATF 16949 (automotive), and ISO 13485 (medical) ensure rigorous controls and traceability.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company that helps engineers and researchers solve complex part challenges in aerospace, medical, and automotive industries. With certifications such as IATF 16949 and AS9100D, the team ensures high-quality solutions through advanced technologies. For more insights, Contact them Today for a free, no-obligation project review and DFM analysis. Turn your concept into a cost-effective reality.