In the United States, high-pressure boilers are a critical part of thermal power plants, industrial steam systems, and engineering education. As power plant operating pressures increased during the mid-20th century, engineers faced serious challenges such as salt deposition, tube scaling, and reduced heat-transfer efficiency.

To address these issues, advanced boiler designs were developed—one of the most innovative among them was the Loeffler Boiler.

The Loeffler boiler is a high-pressure, forced-circulation water-tube boiler that uses superheated steam instead of flue gases to evaporate water. While it is rarely used in modern U.S. power plants today, it remains an important concept in mechanical engineering curricula and competitive exams.

What Is a Loeffler Boiler?

The Loeffler Boiler is a forced circulation, high-pressure water-tube boiler specially designed to overcome the problem of salt deposition and scaling in boiler tubes.

Unlike conventional boilers, water is not directly evaporated by flue gases. Instead, superheated steam is used to evaporate feed water inside a separate evaporating drum.

This unique working principle makes the Loeffler boiler suitable for very high operating pressures.

Why Was the Loeffler Boiler Developed?

In high-pressure boilers:

- Natural circulation becomes weak

- Salt deposition increases rapidly

- Tube failure risk becomes high

The Loeffler boiler solves these problems by:

- Eliminating direct heating of water in tubes

- Using superheated steam for evaporation

- Allowing the use of impure or salt water

Working Principle of Loeffler Boiler

The working principle of the Loeffler boiler is based on indirect evaporation of feed water using superheated steam.

Key Concept

- About 2/3 of the superheated steam is used to evaporate feed water

- The remaining 1/3 of the steam is supplied to the steam turbine

This arrangement prevents scale formation inside boiler tubes, which is a major limitation of conventional high-pressure boilers.

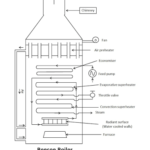

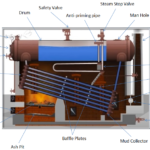

Main Parts of Loeffler Boiler

The main components of a Loeffler boiler are:

- Feed Pump

- Economiser

- Evaporating Drum

- Steam Circulating Pump

- Radiant Superheater

- Convective Superheater

- Mixing Nozzle

Function of Each Part

1. Feed Pump

The feed pump forces high-pressure feed water into the boiler system.

2. Economiser

The economiser preheats the feed water using waste heat from flue gases, improving the overall efficiency of the boiler.

3. Evaporating Drum

- Located at the lower part of the boiler

- Contains mixing nozzles

- Feed water is converted into saturated steam using superheated steam

Note: No direct heating by flue gases occurs here.

4. Steam Circulating Pump

This pump maintains forced circulation of steam between:

- Evaporating drum

- Radiant superheater

- Convective superheater

5. Radiant Superheater

- Installed inside the furnace

- Superheats steam using radiant heat from burning fuel

- Heat transfer occurs mainly by radiation

6. Convective Superheater

- Placed in the path of hot flue gases

- Further superheats steam by convection

- Produces steam at about 500°C

7. Mixing Nozzle

- Installed inside the evaporating drum

- Mixes superheated steam with feed water

- Rapidly converts water into saturated steam

Working of Loeffler Boiler (Step-by-Step)

- Feed water is pumped into the economiser

- Preheated water enters the evaporating drum

- 2/3 of superheated steam is injected through mixing nozzles

- Feed water converts into saturated steam

- Steam is drawn by the steam circulating pump

- Steam passes through the radiant superheater

- Further heating occurs in the convective superheater

- Superheated steam is divided:

- 2/3 → evaporating drum

- 1/3 → steam turbine

Operating Conditions of Loeffler Boiler

| Parameter | Typical Value |

| Steam pressure | ~140 bar |

| Steam temperature | ~500°C |

| Steam generation | ~100 tonnes/hour |

Advantages of Loeffler Boiler

- Eliminates scale and salt deposition

- Can use impure or salt water

- Suitable for very high pressure

- Compact construction

- High thermal efficiency

Disadvantages of Loeffler Boiler

- High initial cost

- Complex design

- Requires power for steam circulation pump

- Higher maintenance compared to simple boilers

Applications of Loeffler Boiler

- High-pressure thermal power plants

- Power generation units requiring pure superheated steam

- Research and experimental boiler systems

Loeffler Boiler vs Conventional Boilers

| Feature | Loeffler Boiler | Conventional Boiler |

| Water heating | By superheated steam | By flue gases |

| Scale formation | Very low | High |

| Pressure suitability | Very high | Limited |

| Complexity | High | Low |

Loeffler Boiler vs Benson Boiler

| Feature | Loeffler Boiler | Benson Boiler |

| Boiler Type | High-pressure | Supercritical |

| Circulation | Forced | Once-through |

| Evaporation Method | Superheated steam | Direct heating |

| Scale Formation | Eliminated | Controlled by water purity |

| Complexity | Very high | Moderate |

| Use in USA Today | Rare | Common |

Conclusion

The Loeffler boiler is an innovative high-pressure boiler design that uses superheated steam instead of direct flue-gas heating.

Its ability to eliminate scaling makes it ideal for understanding advanced boiler engineering concepts, especially for mechanical engineering students and competitive exams.

FAQs: Frequently Asked Questions

To prevent salt deposition and enable operation at very high pressures.

Because 2/3 steam is required to evaporate feed water continuously.

Yes, it is specifically designed to handle impure water.

It is mainly of academic and experimental importance, as modern once-through boilers have replaced it.

Loeffler Boiler – Knowledge Check

⚠️ Please select an option before continuing.