In this article we will learn about scotch marine boiler construction, working, advantages and application. It is the most common boiler which is used on ships in marine works. It is a type of fire tube boiler. After reading this article you will able to learn its construction, types, working and advantages.

Scotch Marine Boiler

It is a fire tube boiler. It is also a scotch or tank type boiler which is used for the marine works. The reason behind, it is used for marine work is its compactness, efficiency in operation and its ability to work in any type of water. Brickwork setting and external flues are not required in this boiler.

Types

It is of two types:

1. Single Ended

2. Double Ended

Single Ended Scotch Marine Boiler:

- The length of the single ended steam boiler may be upto 3.5 m

- The single ended steam boiler contains one to four furnaces and these furnaces enter from the front end of the boiler.

Double Ended Scotch Marine Boiler:

- The length of double ended steam boiler is upto 6.5 m.

- In double ended scotch marine boiler, the furnaces are present on both of its ends. And the number of furnaces varies from 2 to 4 in each end.

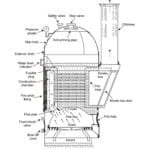

Construction or Main Parts

The various parts of the scotch marine boiler are as follows

1. Furnace:

It is used to burn the fuel inside the boiler. A single ended scotch marine boiler is fired with four furnaces. The furnaces are generally corrugated for strength. Each furnace has its own combustion chamber.

2. Combustion Chamber:

It is a portion of the boiler where the combustion of the fuel takes place. There are fine plates in the combustion chamber , which require staying i.e. the top plate, back plate, two side plate and the tube plate. There are number of smoke tubes placed horizontally and connect the combustion chamber to the chimney.

3. Smoke Box:

The smoke box has numbers of smoke tubes which is placed horizontally and connects the combustion chamber to the chimney. The smoke passes through these smokes tubes and finally enters into the chimney.

4. Chimney:

It is used to exhaust the smoke and burnt gases out of the boiler. The exhaust gases is released into the environment through chimney.

5. Boiler Shell:

The boiler shell is made up of steel plate. It protects the internal parts of the boiler. All the important fittings of the boiler are fitted on the boiler shell.

Also Read:

- Steam Condenser – Definition, Working, Types and Advantages

- Lancashire Boiler Construction, Working with Diagram

- What are Boiler Mountings and Accessories

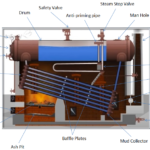

Working of Scotch Marine Boiler

The fuel is inserted into the furnace through the fire hole. The fuel in the furnace is ignited through the fire hole. The burnt fuel enters into the combustion chamber. Here the combustion of the fuel takes place. The heat generated into the combustion chamber is used to heat the water surrounding the combustion chamber. The water gets converted into steam and it is supplies to steam turbine. The exhaust gases after combustion passes through the smoke tubes and reaches to the chimney. The chimney releases these smoke and exhaust gases into the atmosphere. In the scotch marine boiler the water surrounds the furnace, combustion chamber and smoke tubes and due to this it provides the greater heating surface to the water.

For better understanding lets discuss its working step by step.

- First the fuel is inserted into the furnace through the fire hole and here it is ignited.

- The fuel is burnt on the furnace and hot burnt gases are generated. This hot burnt gas enters into the combustion chamber. A large amount of heat is generated into the combustion chamber. The heat form the combustion chamber use to heat the water surrounds it.

- The water gets converted into steam and made to pass on the steam turbine.

- The water surrounds the furnace, combustion chamber and smoke tubes and due to this the scotch marine boiler provides a greater heating surface for the water.

- The burnt exhaust gas passes to the chimney through smoke tubes.

- The chimney releases these exhaust gases or smoke in the atmosphere.

- In this boiler the level of water is maintained a little above the combustion chamber.

Application

This boiler is generally used in marine works and on ships. This is because of its compactness, efficiency in operation and its ability to work in any type of water.

Advantages

- It is compact in size.

- It has a good efficiency in operation.

- It has the ability to work in any type of water.

- Brickwork setting and external flues are not required in this boiler.

This is all about the Scotch Marine Boiler. If you found this piece of information useful than don’t forget to like and share it.