The difference between fire tube boiler and water tube boiler can be done on various points. These points include types of fluid flows within the tubes, steam generation rate, floor area required for the steam generation, transportation, efficiency, fluctuating loads, operating cost etc. the knowledge of the difference about these two boilers is very crucial.

Fire Tube Boiler Vs Water Tube Boiler

| S.no | Fire tube boiler | Water tube boiler |

| 1. | Hot flue gases is present inside the tubes and water surrounds them. | Water is present inside the tubes and the hot flue gases surrounds them. |

| 2. | Low pressure boilers. The operating pressure is about 25 bar. | High pressure boilers and the operating pressure is about 165 bar. |

| 3. | Steam generation rate in fire tube boiler is low, i.e.9 tonne per hour. | Steam generation rate in water tube boiler is high i.e. 450 tonne per hour. |

| 4. | For a given power, the floor area required for steam generation is more i.e. 8 m2 per tonne per hour. | The floor area required for the steam generation is less, i.e. 5 m2 per tonne per hour. |

| 5. | The transportation and erection in this type of boiler is difficult. | The transportation and erection is easy as its parts can be separated. |

| 6. | The overall efficiency of this boiler is upto 75%. | The overall efficiency is upto 90% with the economizer. |

| 7. | It can works on fluctuating loads for shorter period of time. | It works on fluctuating loads all the times. |

| 8. | The direction of water circulation in fire tube boiler is not well defined. | The direction of water circulation in water tube boiler is well defined i.e. a definite path is provided for the circulation of water. |

| 9. | Operating cost is low. | Operating cost is high. |

| 10. | Bursting chance is less in fire tube boiler. | Bursting chance in water tube boiler is more. |

| 11. | Due to bursting, there is a greater risk to the damage to the boiler. | The bursting in this boiler does not produce any major destruction to the whole boiler. |

| 12. | It can be operated with less skilled person. | A skilled person is required to operate this boiler. |

| 13. | Low maintenance cost. | High maintenance cost. |

| 14. | They are light in weight. | They are heavy in weight. |

| 15. | It is suitable for small power plant. | It is suitable for large power plant. |

Also Read:

- Lancashire Boiler Construction, Working with Diagram

- Cochran Boiler – Main Parts, Working, Advantages and Disadvantages

- What is a Boiler? Different Types of Boiler

How Fire Tube Boiler Different from Water Tube Boiler

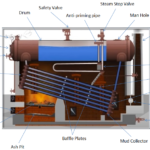

Fire Tube Boiler

- It is a boiler in which the hot flue gases is present inside the tubes and the water surrounds these tubes. As fire is present insides the tubes, hence it is called as fire tube boiler.

- The steam produced by these boilers have pressure of about 25 bar and that’s why they fall under the category of low pressure boilers.

- The steam generation rate in these boilers are low i.e. 9 tonnes per hour.

- For a given power the floor area required for steam generation is more and it is about 8 m2 per tonne per hour.

- The erection and transportation of these boilers are not easy. And this is because their parts cannot be separated.

- If we talk about the efficiency then the overall efficiency of fire tube boilers is about 75%.

- The direction of the water circulation is not well defined i.e. a definite path is not provided for the circulation of water.

- The operating cost of this boiler is low.

- The bursting chance is less. The bursting produces greater risk to the damage of the boiler.

- It is not suitable for large power plants but used in small power plants.

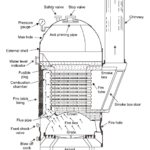

Water Tube Boiler

- It is a boiler in which the water is present inside the tubes and the hot flue gases surrounds the tubes. Since the water is present insides the tubes hence these boilers are called water tube boiler.

- High pressure steam is produced by these boilers. The pressure of the steam is about 165 bar. These boiler falls under the category of high pressure boiler.

- The steam generation rate in water tube boiler is high i.e. 450 tonnes per hour.

- For a given power the floor area required for the generation of steam in this boiler is less i.e. 5 m2 per tonne per hour.

- The erection and transportation is easy as its parts can be separated.

- The overall efficiency of water tube boiler with economizer is upto 90%.

- The direction of the water circulation is well defined i.e. a definite path is provided for the circulation of water.

- The operating cost is high.

- The bursting chance is high because of its high steam pressure. The bursting does not cause any destruction to the whole boiler.

- It is suitable for the large power plant.