The Babcock and Wilcox boiler is one of the most widely recognized high-pressure water-tube boilers used in thermal power plants and large industrial setups. It plays a critical role wherever a continuous supply of high-pressure, high-temperature steam is required—especially for electricity generation. Unlike fire-tube boilers, water flows inside the tubes while hot flue gases pass around them, allowing efficient heat transfer and safer operation at high pressures.

This boiler design became popular because it combines reliability, high steam generation capacity, and ease of maintenance, making it suitable for large-scale power production. Due to its horizontal drum arrangement and natural circulation principle, it remains a foundational topic in mechanical and power plant engineering worldwide.

What is a Babcock and Wilcox Boiler?

The Babcock and Wilcox boiler is a horizontal, stationary, multitubular, externally fired, water-tube boiler operating on natural circulation and natural draft. It is designed specifically for high-pressure steam generation using solid fuels such as coal.

The boiler was developed by George Herman Babcock and Stephen Wilcox, and named after them.

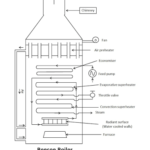

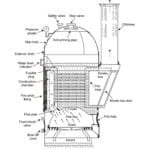

Main Parts of Babcock and Wilcox Boiler

1. Drum

A horizontal cylindrical drum that stores water and collects steam generated from the water tubes.

2. Down-Take Header

Located at the rear end, it supplies water from the drum to the inclined water tubes.

3. Up-Take Header

Situated at the front end, it carries the steam-water mixture back to the drum.

4. Water Tubes

Inclined at about 10–15°, these tubes contain water that absorbs heat from flue gases and converts it into steam. The inclination helps in smooth separation of steam and water.

5. Baffle Plates

They force hot flue gases to flow in a zigzag path, increasing heat transfer efficiency.

6. Fire Door

Used for igniting and feeding solid fuel into the furnace.

7. Grate

Supports the burning fuel and allows air circulation from below.

8. Mud Collector

Placed at the bottom of the down-take header to collect impurities and sediments from water.

9. Feed Check Valve

Controls the entry of feed water into the drum and prevents backflow.

10. Damper

Regulates airflow through the boiler to control combustion.

Also Read:

- What is Gas Turbine Power Plant?

- Locomotive Boiler – Construction Working and Application with Diagram

- Cochran Boiler – Main Parts, Working, Advantages and Disadvantages

Boiler Mountings and Accessories

- Superheater – Raises the temperature of saturated steam to superheated steam.

- Pressure Gauge – Indicates steam pressure inside the drum.

- Water Level Indicator – Shows the water level in the boiler drum.

- Safety Valve – Releases excess steam to prevent over-pressure conditions.

Working of Babcock and Wilcox Boiler

- Feed water enters the drum through the feed check valve.

- Water flows from the drum to the down-take header and then into the inclined water tubes.

- Coal burns on the grate, producing hot flue gases.

- Baffle plates guide these gases in a zigzag path across the water tubes.

- Heat transfer converts water into a steam-water mixture inside the tubes.

- The mixture flows to the up-take header and back to the drum.

- Steam separates from water inside the drum.

- An anti-priming pipe removes moisture, ensuring dry steam.

- Steam passes through the superheater and is supplied to turbines or industrial processes.

Applications of Babcock and Wilcox Boiler

- Thermal power plants for electricity generation

- Large industrial plants require high-pressure steam

- Process industries such as chemical, paper, and textile plants

Advantages

- High steam generation capacity (2000–40,000 kg/hr)

- Suitable for high-pressure applications

- Occupies less floor space

- Easy replacement of defective tubes

- Low draught loss

- Inspection possible during operation

Disadvantages

- High initial and maintenance cost

- Not suitable for impure or sediment-laden water

- Requires a continuous feed-water supply

- Risk of tube overheating if water level is not maintained

Conclusion

The Babcock and Wilcox boiler remains a cornerstone of modern steam power generation due to its ability to safely produce large quantities of high-pressure steam. Its water-tube construction, efficient heat transfer, and adaptability to power plants make it an industry-preferred design even today. While it demands careful water treatment and maintenance, its performance advantages outweigh these limitations. Understanding its construction and working principle provides a strong foundation for exploring advanced boiler systems and thermal power technologies.

Frequently Asked Questions (FAQs)

It is a water-tube boiler where water flows inside the tubes.

Because it can safely generate high-pressure steam in large quantities.

Natural circulation.

Coal is the most commonly used fuel.

They increase heat transfer by directing flue gases in a zigzag path.

To ensure easy separation of steam and water.

No, it is mainly designed for high-pressure steam generation.

The boiler may overheat, leading to tube damage.

By using anti-priming pipes and superheaters.

Yes, to prevent scale formation and tube failure.

Babcock and Wilcox Boiler – Knowledge Check

Please select an option before continuing.