Introduction to CNC Machining in E-Bikes

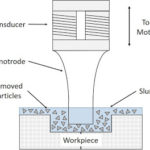

Computer numerical control CNC is an advanced machining process using pre-programmed multi-axis machine tools guided by computer instructions to remove excess material from a workpiece.

5-axis CNC machining has been the primary method to manufacture e-bikes and their components due to its ability to achieve tight tolerances of up to 0.01mm. This is crucial to ensure proper functionality and meet safety and regulatory standards.

E-bikes must be lightweight and durable to support higher power efficiency and meet quality standards. CNC machining allows complex part geometry for various materials used in the bicycle industry.

This article provides an oversight of how CNC machining supports the manufacturing of e-bikes and enables various complex geometries for motor housings and components, while reducing processing time by rapid iteration.

Lightweight and Durable Frame Parts

E-bikes have to be lightweight and also durable to support heavy loads. CNC machining can process high-strength alloys such as 6061-T6 or 7075 aluminum alloys in addition to fiber and composite materials.

These materials have high strength-to-weight ratios paired with good machinability. This allows 5-axis machines to process various profiles such as tube, chamfer, and tapers.

For example, E-bike frames are milled to have pre-built battery and accessory mounts. In addition, these frames also have internal structures that reduce weight without compromising durability.

Post-processing procedures, such as surface treatment like anodizing finishes, improve corrosion resistance and increase the longevity in demanding environments. CNC machines have reduced frame weight up to 20% compared to traditional welded bike frames

Customization and Prototyping of Designs

CNC machining is a subtractive process that enables rapid prototyping and customization due to its speed and efficiency.

The process eliminates the need for expensive tooling and repetitive mold making with significant production time.

With the help of CAD, designs can be virtually altered and tested. CNC machines produce machined parts using translation software such as Fusion 360, which transforms CAD design into G code for the CNC machine.

Bike parts such as handlebars are machined and tested to reiterate and adjust the design and shape, enabling better performance and functionality.

CNC machines also enable various material options, such as aluminum and composite materials, allowing manufacturers to compare options to find the perfectly balanced material.

It also allows small batch runs to test markets and receive feedback to improve design and durability. CNC prototyping supports flexibility and innovation in frame manufacturing

Also Read:

- Advantages of Electron Beam Machining

- What is Electron Beam Welding? – Complete Explanation

- What is Electron Beam Machining? A Complete Guide

High-Performance Motor and Battery Housings

CNC machining has an extremely tight tolerance of 0.01mm and material versatility that allows manufacturers to make motor and battery housing using materials such as 7075 aluminum, which is durable and has excellent thermal properties.

The tight tolerance also ensures proper motor stator alignment, reducing vibration and improving efficiency. Additionally, CNC machines allow manufacturers to design cooling fins for adequate heat dissipation.

CNC machining allows cooling channels with a precision of ±0.02 mm, for liquid coolant systems in the battery housing.

Using CNC machines eliminates the need for welding, improving durability and reducing vibration. For example, a CNC-milled battery enclosure with integrated mounting brackets ensures a secure fit for 48V lithium-ion packs, maintaining IP67 waterproofing.

This improves the battery life by optimizing performance and reducing operational temperatures by 10°C

Enhanced Brake and Gear System Components

E-bikes travel at higher speeds and have significant weight due to the battery pack and motor housing, so braking and gear systems must be reliable and durable.

Brake parts are typically CNC machined from durable T6 6061 aluminum, which ensures durability and tolerances as tight as 0.005mm for steady and consistent braking.

Using 5-axis machines allows complex caliper geometries and optimizes stiffness-to-weight ratios to handle large forces for emergency braking.

Chainrings and sprockets used in gears have tight tooth profiles tachined using CNC to ensure proper fitting and alignment.

The material options that CNC machining provides allow for durable gear components that can withstand high tensile strengths. These components enhance drivetrain efficiency, with CNC-machined parts reducing chain wear by up to 20% (per Shimano technical data).

Rapid Iteration for Innovative Designs

CNC machines have minimal production time and optimize efficiency. This allows rapid iteration for quick design revamps and adjustments.

The CNC machines run on G-code that is extracted from CAD models. The code guides the machine in producing highly accurate prototypes with excellent surface finish.

This allows engineers to test components like motor mounts or frame junctions under real-world conditions, such as 500 Nm torque loads from mid-drive motors.

The design is refined and iterated with data gathered from thermal imaging and strain gauges to optimize performance.

For example, various battery housing designs can be machined to test and compare parameters such as fin density, material, and heat dissipation.

CNC’s flexibility supports small-batch runs for consumer feedback to iterate frame designs to integrate better components and sensors

This process ensures e-bike innovations, such as aerodynamic fairings or modular battery mounts, reach the market faster. This minimizes development timelines by 30–50% compared to traditional methods.

Cost Efficiency in Small-Batch Production

CNC machining is more cost-efficient as it eliminates hot ends for expensive tools required to make injection molds. CNC machining costs 10 times less than injection molding, which costs around $10,000–$50,000 per mold.

CNC also supports small batch runs, ideal for teasing design and market trends to automate CNC processes, using high-speed spindles (15,000–24,000 RPM), reducing machining time by 20–30%, and lowering labor costs.

The wide range of material options available to manufacturers that use CNC machines gives them a significant advantage. Additionally, virtually optimizing tool paths to efficiently use material improves cost efficiency.

This cost structure enables manufacturers to produce custom frames or components competitively. Reducing the cost by around 40% compared to casting.

Conclusion

CNC machines play a significant role in innovative design and component production, driving global competition. It has enabled manufacturers to make lightweight, durable frames that can be modified and custom-tailored to specific needs.

The addition of rapid iteration and small batch production in the manufacturing industry has driven innovation to meet the market demands

The spreading of E-bikes will further fortify the use of CNC procedures in manufacturing, making it crucial for producing reliable and durable parts that meet safety standards.