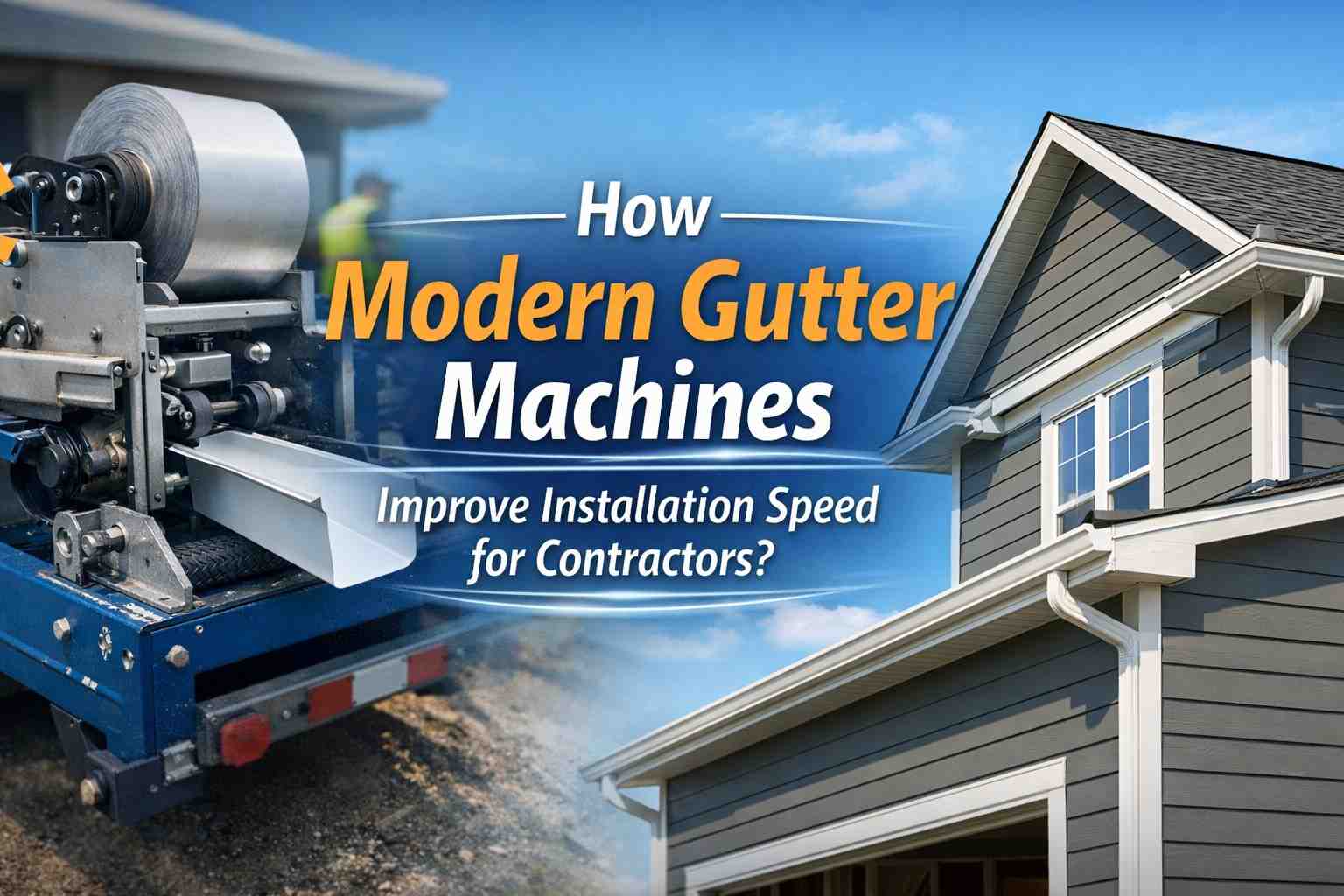

In the fast-paced construction industry, time efficiency directly impacts profitability and client satisfaction. For contractors installing rain gutters, having the right equipment can significantly shorten project timelines while maintaining precision and quality. Modern gutter machines have become essential for this reason, enabling the seamless on-site production of custom-fit gutters.

Unlike older methods that required prefabricated materials or manual shaping, today’s machines deliver smooth, continuous sections with minimal waste by applying principles similar to roll forming machines. Their advanced technology and ergonomic design help contractors handle multiple jobs faster without compromising craftsmanship.

Understanding how these machines accelerate installation offers valuable insight into their growing demand across the industry.

How Technology Enhances Efficiency

Modern gutter machines have evolved through cutting-edge engineering, transforming how contractors approach installations. How automation, advanced materials, and digital controls work together to boost performance aligns closely with automation in manufacturing.

Many of today’s models feature programmable settings that allow operators to adjust gutter profiles and sizes instantly without manually changing parts. Hydraulic and electric drive systems, based on proven hydraulic machines, deliver a steady output and prevent material distortion, resulting in consistent results.

These innovations not only reduce human error but also streamline workflow by eliminating downtime between jobs. Compact and mobile designs also enable contractors to bring the machine directly to the job site, reducing transportation and assembly time.

With automation handling much of the shaping and cutting, crews can focus on fitting and fastening, completing installations significantly faster. This combination of convenience, speed, and accuracy is reshaping project timelines in the gutter installation field.

How Precision Engineering Saves Time

Precision plays a vital role in installation speed. How accurate measurements and automated cutting capabilities reduce rework and waste reflects the importance of precision engineering.

Older gutter fabrication methods often led to inconsistencies that required on-site manual adjustments, slowing progress. Modern systems, however, rely on digital calibration and computer-guided rollers similar to CNC machines that ensure every section meets exact specifications.

This eliminates guesswork and ensures perfect alignment once installed. Machine operators can switch between materials such as aluminum, steel, and copper with minimal setup time, enabling uninterrupted production.

Some manufacturers, such as KWM gutter machines, are renowned for incorporating built-in measurement tracking and self-correcting alignment systems that maintain flawless uniformity. This precision ensures that contractors can cut, form, and install gutters in a single streamlined process.

When each component fits correctly on the first try, the overall installation pace improves, saving hours on large-scale projects.

How Portability Increases On-Site Productivity

Mobility has become a defining factor in modern gutter installation. How portable and trailer-mounted machines enable faster, more flexible on-site operations mirrors trends seen across construction equipment.

Contractors no longer need to rely on factory-cut sections that require additional transport and storage space. Instead, they can fabricate gutters on demand, tailoring each run to the property’s exact dimensions.

This eliminates delays caused by missing or damaged materials and reduces waste associated with offcuts. Portability also allows crews to set up near the work area, minimizing time spent moving materials.

Many modern units feature lightweight frames and durable wheels, making them easy to maneuver between job sites. This mobility enables smaller crews to handle larger workloads efficiently, improving productivity without adding labor.

With fabrication and installation happening simultaneously, contractors can complete more jobs in less time while maintaining consistent, high-quality results for every project.

How Maintenance Efficiency Supports Performance

Smooth operation depends on machines that require minimal downtime. How easy maintenance and user-friendly designs help contractors maintain productivity aligns with best practices in machine maintenance.

Modern gutter machines are built with accessible components and simplified systems that reduce maintenance time. Features such as quick-change rollers, self-lubricating mechanisms, and automated cleaning cycles help prevent buildup and wear.

This reduces the frequency of breakdowns and ensures uninterrupted operation throughout demanding schedules. Digital diagnostic tools alert users to potential issues before they become major problems, allowing for preventive action.

Regular upkeep can be performed quickly on-site, eliminating the need for lengthy service appointments or off-site repairs. These design advancements not only improve reliability but also reduce the long-term cost of ownership.

With minimal downtime and greater operational stability, contractors can rely on their machines to meet project deadlines and deliver consistent, timely results across multiple installations.

How Safety Enhancements Speed Up Workflow

Safety and efficiency often go hand in hand. How modern gutter machines incorporate safety features that also promote faster work reflects established industrial safety principles.

Machines equipped with automatic shutoff sensors, guarded blades, and ergonomic controls allow operators to work confidently without unnecessary risk. These safety mechanisms reduce accidents, protect workers, and prevent costly delays.

Ergonomically designed control panels and adjustable feeding systems minimize fatigue during long working hours. Contractors can maintain productivity levels throughout the day without compromising accuracy.

Training operators on modern equipment is also quicker due to intuitive digital interfaces and clear display prompts. By reducing both physical strain and operational risk, these features create an environment where crews can focus fully on performance.

Safety no longer slows production—it enhances it, allowing contractors to meet tight deadlines with fewer interruptions and greater precision.

How Automation Reduces Labor Demands

Automation is transforming how contractors handle gutter production, simplifying workflows and reducing manual labor through industrial automation.

Features such as automatic coil feeding, preset cutting lengths, and digital roll-forming programs eliminate repetitive tasks. One operator can now handle what previously required multiple team members.

This not only lowers labor costs but also increases output per worker. Automated adjustments maintain consistent pressure and speed, ensuring uniform results across long runs.

Some models even feature touchscreen controls that let users save preferred settings for future jobs, dramatically reducing setup time. As a result, crews can start production almost instantly upon arrival at the site.

The combination of fewer steps, reduced labor input, and high-speed automation enables contractors to complete more installations each week while maintaining steady quality. The efficiency gained translates directly into profitability and customer satisfaction.

How Technology Shapes Long-Term Profitability

The long-term impact of modern gutter machines extends far beyond speed alone. How efficiency, precision, and durability enhance profitability over time is closely tied to manufacturing efficiency.

Faster installations mean more completed projects, leading to increased revenue potential. Reduced waste and lower maintenance costs further strengthen margins. Machines built with modern technology are also designed to adapt to evolving industry standards, ensuring long-lasting value.

Contractors benefit from consistent performance, fewer delays, and stronger client relationships through timely delivery. Furthermore, the ability to produce gutters on demand allows for flexible scheduling, minimizing downtime between contracts.

As construction demand grows, the productivity gains from modern equipment help businesses scale operations without significant increases in labor or overhead costs. These long-term efficiencies position contractors to remain competitive in an industry where time and accuracy define success.

Conclusion

Modern gutter machines represent a significant advancement in construction technology, enabling contractors to balance speed and quality. Their automated systems, precision engineering, and portability simplify operations while maintaining consistent output.

By reducing manual labor, downtime, and material waste, these machines redefine what efficient installation looks like in today’s market. Brands that invest in such technology gain a competitive edge through faster turnaround times and improved customer satisfaction.

As the industry continues evolving, adopting these innovations will remain key to staying productive and profitable. For contractors, modern gutter machines are not just tools—they are the future of streamlined, high-performance installation.