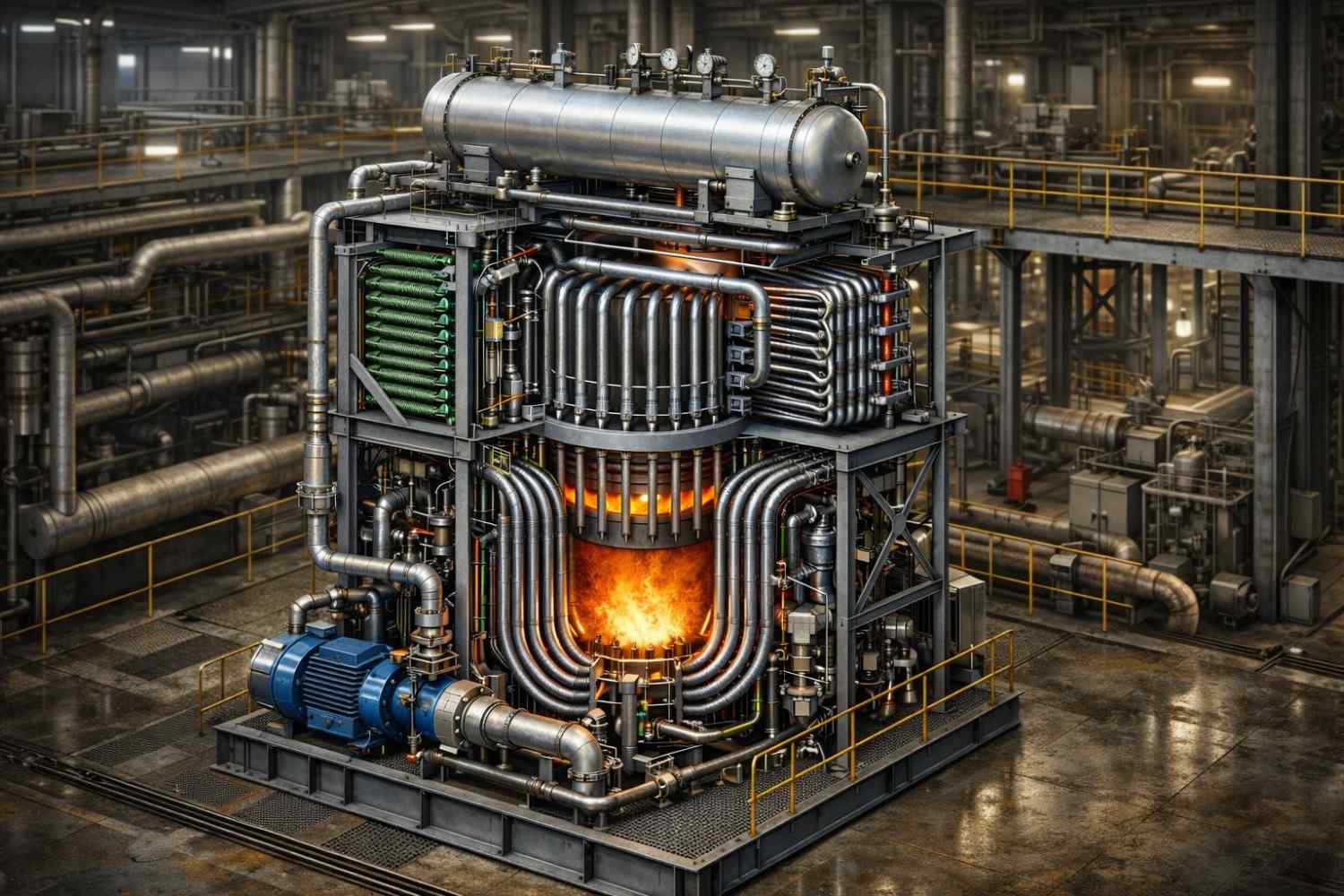

The Lamont boiler is a high-pressure, forced-circulation water-tube boiler designed to generate large quantities of steam efficiently within a compact space. Unlike natural circulation boilers that rely on density differences, this boiler uses an external pump to circulate water at high velocity through small-diameter tubes. This design significantly improves heat transfer and allows the boiler to operate safely at very high pressures.

Developed in 1925 by Walter Douglas La-Mont, the Lamont boiler was initially intended for marine and power-generation applications where quick startup and high steam demand were essential. Even today, it remains an important reference boiler in mechanical and thermal engineering because it clearly demonstrates the concept of forced circulation and high-pressure steam generation used in modern power plants.

What Is a Lamont Boiler?

A Lamont boiler is a high-pressure, water-tube boiler that uses forced circulation of water through evaporator tubes with the help of a centrifugal pump. The boiler includes an internally fired furnace and a steam-separating drum to ensure dry, high-quality steam output.

Typical operating parameters:

- Pressure: ~170 bar

- Steam temperature: ~773 K

- Steam generation capacity: ~50 tonnes/hour

Working Principle of Lamont Boiler

The Lamont boiler works on the forced circulation principle. Instead of depending on natural convection, a centrifugal pump continuously circulates water through the boiler tubes at a high rate.

Because the water velocity is high, heat transfer from hot flue gases to water is rapid, and the risk of overheating tubes is reduced. The circulation pressure is much higher than in natural circulation boilers, enabling stable operation even at very high pressures.

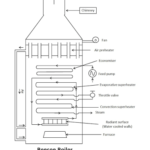

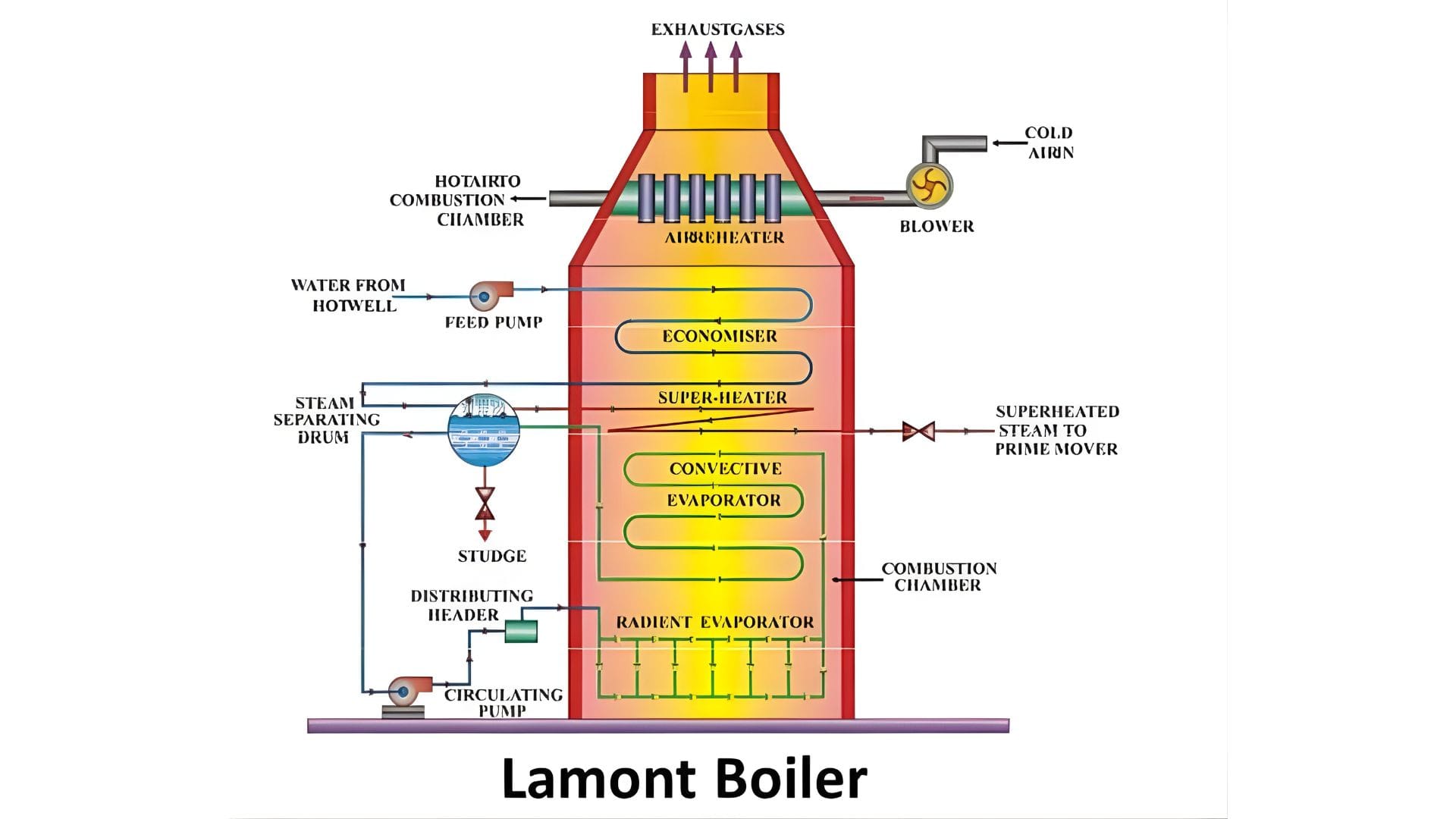

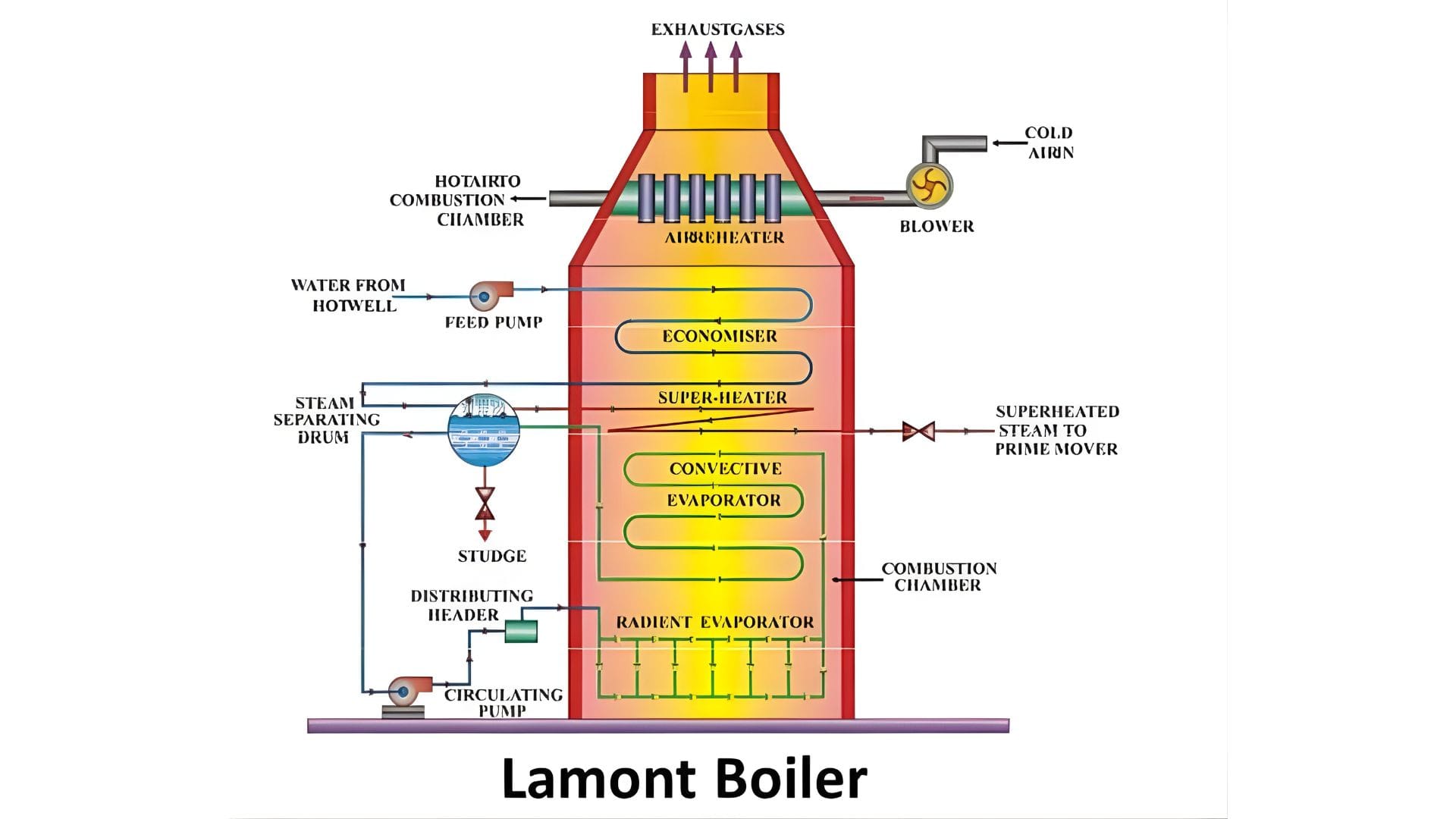

Main Parts and Construction of Lamont Boiler

1. Feed Pump

Supplies feed water from the hot well into the boiler system.

2. Economizer

Preheats the feed water using waste heat from flue gases, improving overall efficiency.

3. Steam Separating Drum

Separates steam from the steam–water mixture. Steam collects at the top, while water settles at the bottom for recirculation.

4. Circulating Pump

A high-capacity centrifugal pump that forces water from the steam drum through the evaporator tubes and back to the drum.

5. Radiant Evaporator

Receives heat mainly by radiation from the furnace and initiates evaporation of water.

6. Convective Evaporator

Further converts the steam–water mixture into saturated steam using convective heat transfer.

7. Superheater

Raises the temperature of saturated steam to the required superheated state before it enters the turbine.

Also Read:

- Difference Between Fire Tube Boiler and Water Tube Boiler

- Cochran Boiler – Main Parts, Working, Advantages and Disadvantages

- Lancashire Boiler Construction, Working with Diagram

Working of Lamont Boiler (Step-by-Step)

- Feed water is pumped into the economizer, where it is partially heated.

- Heated water enters the steam separating drum.

- From the drum, water is forced through the radiant evaporator by the circulating pump.

- The water–steam mixture then flows through the convective evaporator, where most water converts into saturated steam.

- The mixture returns to the steam drum, where steam is separated.

- Dry saturated steam passes through the superheater and becomes superheated steam.

- Superheated steam is supplied to a turbine or a steam header for power generation.

Applications of Lamont Boiler

- Thermal power plants

- Marine propulsion systems

- Industrial process heating

- Research and educational demonstrations of forced circulation boilers

Advantages of Lamont Boiler

- Quick startup compared to natural circulation boilers

- High steam generation capacity

- High heat transfer rate due to forced circulation

- Compact design suitable for high-pressure operation

- Can be adapted to systems originally designed for natural circulation

Disadvantages of Lamont Boiler

- Bubble formation on tube surfaces can reduce heat transfer

- Complete dependence on the circulating pump

- Higher operational and maintenance complexity

- Pump failure can lead to serious overheating issues

Conclusion

The Lamont boiler clearly demonstrates how forced circulation can enhance heat transfer and enable safe operation at very high pressures. With its compact design, rapid startup, and high steam-generating capacity, it played an important role in the evolution of modern high-pressure boilers. While it is not as widely used today, understanding the Lamont boiler provides valuable insight into the principles behind contemporary power plant boilers and advanced steam generation systems.

Frequently Asked Questions (FAQs)

It is a high-pressure water-tube boiler.

Forced circulation using a centrifugal pump.

It allows high heat transfer and safe operation at very high pressures.

It was invented by Walter Douglas La-Mont in 1925.

To separate steam from the water–steam mixture.

They increase heat transfer efficiency and withstand high pressure.

Around 50 tonnes per hour.

No, pump operation is essential for circulation.

Mainly in ships and marine applications.

It is less common today but remains an important design reference.

Lamont Boiler – Knowledge Check

Please select an option before continuing.