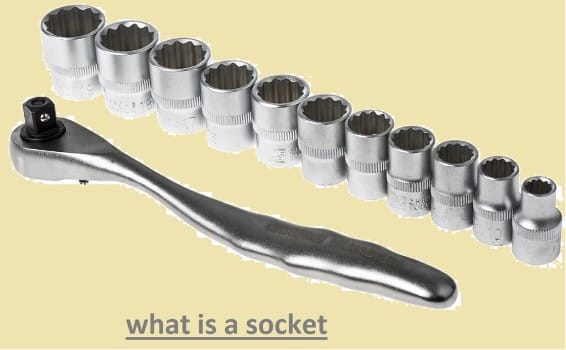

Sockets normally work with a combination of ratchets. socket is connected at one end of the ratchet through use of a driver connector. At the other end of the socket is connected to the fastener. The ratchet helps the socket to manage and strongly tighten fasteners by turning in a clockwise direction and loosen fasteners through rotation in a counterclockwise direction.

The socket size chart is an important tool that helps us to use sockets for different applications, engineering devices, and parts. The socket size chart follows SAE and metric socket dimensions for related drive sizes that come in different sizes like ¼-inch, ⅜-inch, and ½-inch. Here, we will cover details for sockets and socket size charts for practical understanding.

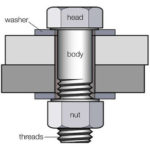

What Is A Socket?

- The socket connects to the ratchet end or wrench for removing bolts. The socket is configured with two sides, one with grip bolts and the other connected with a wrench.

- A socket wrench is a wrench that makes a connection with a socket and helps us for the application of fasteners. Some socket wrench types come with a ratcheting system that helps us pivot the bolt in reverse and forward to loosen or tighten.

- It helps not to spin completely round for loosening or tightening fasteners that are preferred for tight spaces.

- Some come in different imperial and metric sizes.

Socket Drive Sizes

- A socket normally comes with 5 different size values, like 1/4”, 1/4”,3/8”, 1/2”, 3/4”, and 1”. This drive size is related to the drive used on the ratchet tool. Normally, a larger socket size shows a larger drive size needed. This parameter is used for socket and ratchet tools.

- Adapters are also used to allow socket tools having different drive sizes to be used simultaneously.

Types of Sockets

Different sizes exist for sockets that are used for different applications; according to ratchet type, they are made to be used with or without fasteners, where employed. Commonly used socket types are mentioned here.

Hex Sockets

- Hex sockets are a very common type of socket. It is commonly used with two types: hex 6-point and bi-hex, which has 12 points. A hex socket comes with a square drive connector at one side that makes a connection with a ratchet and a hexagonal recessed head at the other side that turns fasteners like nuts and bolts.

Screwdriver Sockets

- Socket bits are made with screwdriver bit and hex socket combinations. It makes a connection to the ratchet through a square drive connector as a hex socket, and the other side of the socket bit is connected to the recess on the fastener head.

- It comes with a Phillips screwdriver head, a flat-headed screwdriver, or other types.

- Socket bits come in two main types: one-piece and two-piece. The one-piece socket bit comes with a screwdriver bit fixed at the reverse side of the square drive connector and molded into the driver bit design.

- Two-piece socket bits come with a socket layout, and a removable screwdriver bit exists at the position through the screw.

- These two types also have sizes and shapes that differ according to the fastener head.

Pass-Through Sockets

- This socket type is different from others since it does not have a square drive connector. since they were made for turning through a ratchet that was configured over the upper side of the socket. This socket is hollow; that helps longer fasteners to pass through.

- It is good for tightening or loosening nuts on long bolts.

Spline Sockets

- spline socket made for tightening and loosening spline fasteners, and good for use on hex and bi-hex fasteners, like nuts and bolts.

- So it is good to use for different fastener types. This socket type provides double torque on the spline fastener that is given to the bi-hex fastener through the bi-hex socket.

Impact Sockets

- This socket type is made with cordless impact wrenches and made with chrome molybdenum, which has features for impact action through breaking. Normally this type comes with thick walls as compared to a standard socket and locking pin for providing that it does not come at the impact wrench end.

- This socket is used in the vehicle and aviation industries.

Torx Sockets

- A Torx socket comes with 6 points in the heads, making a star-like design. It is made for fitting Torx screws and has different sizes. The Torx socket is made for applications of proper torque without slipping features. It is good for heavy-duty applications.

Universal Sockets

- This socket type comes with a spring-loaded pin in the actual socket head. If a socket is put over the fastener head, the spring-loaded pin makes a connection with the fastener. that make the pin accurately cover the fastener head, helping the socket fit different sizes and fastener designs.

- Universal socket good to use for setting damaged fasteners.

Also Read:

- Different Types of Screws in Fastening Process

- Types of Screwdrivers and Their Uses (Complete Guide)

- Parts of a Car: Everything You Need to Know

Socket Size Chart

- Here is a socket size chart made that helps to use sockets for different applications.

- SAE (Imperial) Socket Sizes – Inches

| Fractional Size | Decimal (inches) |

| 1/8″ | 0.125″ |

| 5/32″ | 0.156″ |

| 3/16″ | 0.188″ |

| 7/32″ | 0.219″ |

| 1/4″ | 0.250″ |

| 9/32″ | 0.281″ |

| 5/16″ | 0.313″ |

| 11/32″ | 0.344″ |

| 3/8″ | 0.375″ |

| 7/16″ | 0.438″ |

| 1/2″ | 0.500″ |

| 9/16″ | 0.563″ |

| 5/8″ | 0.625″ |

| 11/16″ | 0.688″ |

| 3/4″ | 0.750″ |

| 13/16″ | 0.813″ |

| 7/8″ | 0.875″ |

| 15/16″ | 0.938″ |

| 1″ | 1.000″ |

Socket Wrench Vs Ratchet

The basic difference between Socket Wrench vs Ratchet is as.

Design

- A socket wrench is a tool that uses manual force for turning fasteners. needed repositioning when a single turn was completed. A ratchet wrench follows a ratcheting system, providing continuous turning without using a repositioning instrument.

Efficiency

- A socket wrench has slow operations and is highly labor intensive, providing high control for different conditions. A ratchet wrench is a high-speed and effective tool and is preferred for closed spaces since it follows a ratcheting mechanism.

Applications

- A socket wrench has the option to use space that is low or for applications where accurate control is needed through certain torque.

- A ratchet wrench is good where high-speed operation and easy use are needed, like in confined spaces.

Electrical Sockets

AC Power Sockets:

- Electrical devices have features for accessing power sources through AC power sockets in homes. Each area comes with a plug type and voltage valve, and each location has certain socket types. Type A and type B are used in North America and Japan.

- The type C socket comes with 2 round prongs and is used in Europe.

- The type G socket used in the United Kingdom and Ireland comes with rectangular prongs and fuses.

- For travelling to other countries, use plug adapters and multi-sockets.

DC Power Sockets:

- Laptops and other portable electronics use DC power sockets that are called special connectors. through a DC socket, current flows in one direction, rather than varying through AC sockets.

- It is designed through positive and negative connections for supporting devices at the ends of the positive and negative connections.

- The power connection should have reliable features and operate well.

Conclusion

Sockets are versatile tools that play a vital role in tightening and loosening fasteners across mechanical, automotive, and electrical applications. By understanding the different socket types, their drive sizes, and the socket size chart (SAE & metric), you can easily select the right tool for the job. Whether you’re working in tight spaces with a ratchet, handling heavy-duty applications with impact sockets, or using universal sockets for damaged fasteners, the correct choice improves efficiency and safety.

For professionals and DIY enthusiasts alike, knowing the features, uses, and size compatibility of sockets ensures precision, durability, and better results in every project.