Engineering makes industrial processes possible. Global supply chains would fall apart if facilities couldn’t maintain their necessary temperatures. Anyone interested in engineering should learn about the best cooling systems for high-temperature industrial processes to understand why they’re vital. The minds behind them will always need more support to advance their solutions and make them more effective.

Why High-Temperature Cooling Systems Are Necessary

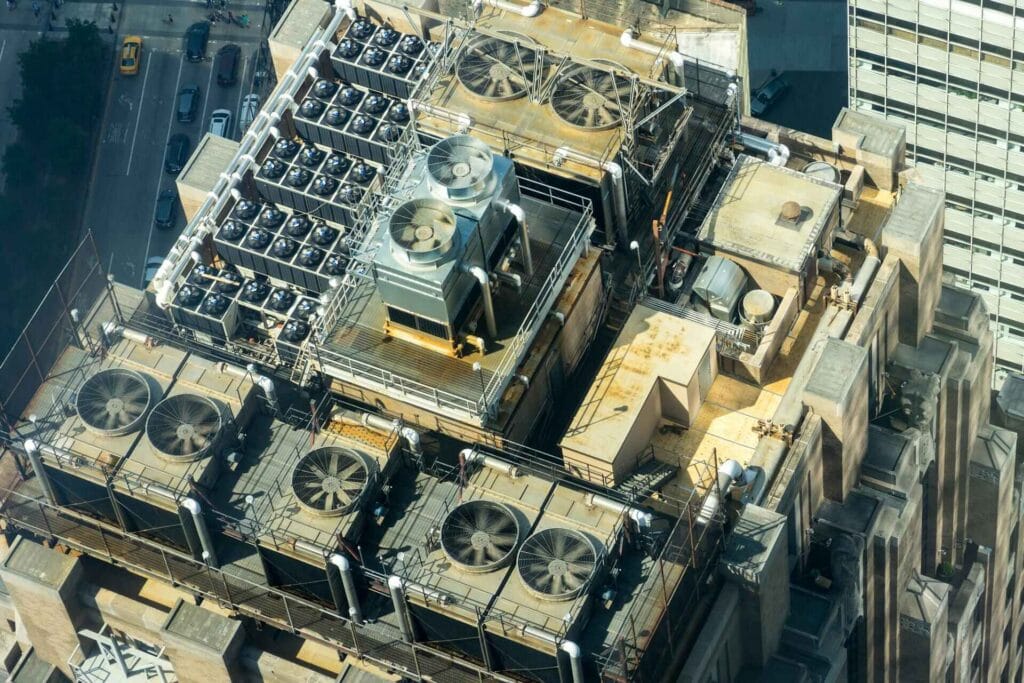

Multiple industries depend on cooling systems for everyday processes. Power plants, treatment facilities, metal manufacturing and major warehouses require temperature regulation to maintain machinery and keep team members safe. The systems may also operate around the clock, depending on the facility’s production schedule.

Some coolant providers meet that need by installing permanent units or rental equipment. If a warehouse’s existing coolers have downtime for repairs, the teams can’t continue working without a cooling system. Rental units ensure that temperature control units are available on short notice, in custom sizes and within a range of budgets.

Cooling System Manufacturers to Consider

People interested in industrial temperature control systems should note what leading manufacturers provide. Their groundbreaking units and high-quality services give industry leaders options for their differing workplace needs.

1. Smart Family of Cooling Products

The team behind Smart Family of Cooling Products understands that industrial processes produce dangerous amounts of heat. The company’s 10–150-ton industrial chillers regulate those temperatures for business clients who need rental units for medical purposes, petrochemical processes, heavy plastic manufacturing and more.

Their expertly engineered equipment make Smart Family of Cooling Products a leading provider of cooling systems for high-temperature industrial processes. Equipment can arrive in custom sizes and last several years longer than comparable units from other manufacturers.

| Smart Family of Cooling Products | ||

| Cooling Products Available | Services | Notable Features |

| Industrial scroll chillers Industrial HVAC products Air-cooled screw chiller | Maintenance Chiller and HVAC service Handling all brands and models Complete unit replacement Design analysis Repairs Services for rotating equipment applications | Explosion-proof Customized low temperature Rental-ready Auxiliary equipment Screw chillers Refrigeration maintenance |

2. Atlas Copco

Atlas Copco is a leading provider of cooling systems. The company’s water and air chillers have around-the-clock monitoring and technology that reduces the equipment’s electricity reliance. Industrial leaders can also integrate Atlas Copco coolers with the brand’s compressed air products. The flexibility creates more opportunities for seamless integration.

| Atlas Copco | ||

| Cooling Products Available | Services | Notable Features |

| High-performance water and air chillers | Preventive maintenance Total responsibility Fixed-price services Genuine parts plan SMARTLINK 24/7 monitoring | Energy-efficient All-in-on installations Multi-industry supportive |

3. Drake Chillers

Manufacturers trust Drake Chillers products because the company specializes in designing and manufacturing chillers. Clients can choose from multiple types of cooling systems, including portable and custom-designed products. Drake Chillers team members have extensive knowledge in creating and managing coolers, so they help customers daily.

The company also works with clients to develop cooling solutions for product-specific production facilities, like food and beverage warehouses. Custom ordering needs won’t prevent any professional teams from accessing Drake Chillers coolant equipment.

| Drake Chillers | ||

| Cooling Products Available | Services | Notable Features |

| Packaged air-cooled chillers Split-system air-cooled chillers Packaged water-cooled chillers Tank systems Heat exchangers Fluid coolers And more | Customized chiller solutions Fast shipping Discounts Extended warranties | After-sales technical support Custom engineering Multi-industry supportive |

4. Dynamic Air Cooling

Dynamic Air Cooling (DAC) provides a range of temperature control products. Businesses from warehouses to offices rely on DAC for custom systems tailored to their unique workplace measurements. The company’s refrigeration technology is energy-efficient and known as a reliable cooling system compared to its competitors. If industrial teams are interested in a custom solution investment, a DAC system could save energy costs long-term and help people meet their sustainability goals.

| Dynamic Air Cooling | ||

| Cooling Products Available | Services | Notable Features |

| AC refrigeration technology | Appliance implementation and testing | Fast cooling No liquids 30% energy efficiency compared to vapor compression Temperature delta -60 degrees Celsius (-76 degrees Fahrenheit) |

5. Ambiator

Professional teams seeking eco-friendly cooling systems often turn to Ambiator. The India-based company has a unique cooling mechanism that depends on water-saturated pads and fresh air from the surrounding region. Sustainability is a leading motivator behind the product’s design.

Ambiator customers enjoy much lower energy bills, smaller carbon footprints and chemical-free temperature management solutions. The global shipping options and accessible tech support team ensure that no interested customer is too far from assistance.

| Ambiator | ||

| Cooling Products Available | Services | Notable Features |

| Ambiator AC cooler | Hassle-free installation Works with locally based contractors Wi-Fi remote control Tech support Free and extended warranties available | 100% fresh air 80% lower electricity bills Lower cost Less maintenance Made with eco-friendly materials |

6. Accelsius

Accelsius provides game-changing cooling solutions for data centers. The company’s technology uses no water, making it a greener option than traditional liquid-based cooling machinery. Each product can handle high temperatures and extreme power demand to keep up with data center activities. Dense servers won’t deal with energy allocation issues due to Accelsius’s electricity-efficient engineering.

| Accelsius | ||

| Cooling Products Available | Services | Notable Features |

| NeuCool liquid cooling NeuCool in-rack system NeuCool four-way GPU thermal conductivity configurator | White-glove support Lifetime value Planned, staged and optimized risk reduction program Comprehensive support and warranty program | Zero water consumption 80% reduced carbon emissions Payback in one to two years 1,500W+ cooling capabilities 50% energy savings |

Also Read:

7. Munters

Industrial processes are easier to manage with Munters temperature-regulating technology. The company works with clients to create cost-effective solutions for data centers, agricultural buildings, commercial facilities and more. Large facilities and intense production demands won’t phase Munters technology.

Teams interested in improving their warehouse humidity or saving electricity can do both with Munters cooling systems. Experienced in-house engineers are ready to assist with questions, resolve unplanned downtime and replace parts to protect each client’s investment.

| Munters | ||

| Cooling Products Available | Services | Notable Features |

| Evaporation cooling system Compact air cooler Direct evaporation coolers and humidifiers Dehumidification systems CW, DX and hermosiphon split coolers And more | Global service network Installation, startup and commissioning Maintenance and repairs Retrofitting and upgrades | Reliable Cost-effective Energy-efficient Multi-industry supportive |

8. Ecochillers

Ecochillers has been making cooling systems for decades, making the company one of the most experienced brands in custom-made coolants. The powerful components provide unmatched efficiency for even heavy-duty applications like health care facilities and data centers. Anyone with unique facility concerns can also arrange a design appointment. Ecochillers experts consult new clients about custom systems for each business’s size, needs and sustainability goals.

| Ecochillers | ||

| Cooling Products Available | Services | Notable Features |

| Centrifugal oil-free chillers Ecogreen screw chillers Inverter, York and Carrier chillers And more | Consulting basis or part-of-system purchase possible Application, facility, budget and environmental reviews Custom system designs | Five to 250 tons Reduced operating costs Reliable operations Easy to operate Indoor and outdoor designs |

9. O2 Natural Air

O2 Natural Air supports temperature regulation in multiple ways. The company’s leading products provide new cooling system arrangements for facilities needing better equipment. Interested customers can also improve their existing systems with O2 Natural Air’s capacity-boosting equipment. The company’s lack of synthetic refrigerants also makes it an eco-friendly coolant provider. If industrial facilities are under strict environmental regulations, O2 Natural Air’s engineering could be optimal.

| O2 Natural Air | ||

| Cooling Products Available | Services | Notable Features |

| Two-stage adiabatic cooling systems Indirect and direct evaporative cooling | Cools with filtered outside air Meets international regulatory standards | 60% less moisture 90% lower energy consumption Sustainable Cost-effective Multi-industry supportive |

10. Daikin

Global industry leaders rely on Daikin for its effective cooling machinery. The company’s range of products gives clients more options within air-cooled and water-cooled engineering setups. Operational efficiency is at the top of Daikin’s manufacturing teams’ minds.

The company’s products can handle large capacity production volumes, intense energy demands and around-the-clock manufacturing. Medium- and large-scale facilities may have better temperature regulation experiences with Daikin to support their operations.

| Daikin | ||

| Cooling Products Available | Services | Notable Features |

| Air-cooled chillers Water-cooled chillers | Lower maintenance costs Versatile to each venue’s cooling needs Cost-savings performance Preventive maintenance | Large capacity chillers (6,000 tons in one unit) High operational efficiency Outstanding durability |

Why Expert Cooling Machinery Is So Important

Maintaining the temperature within an industrial space isn’t as simple as turning on a thermostat. Companies need specialized engineering to cool machinery for multiple reasons.

The Heat Transfer Process Is Complicated

Many manufacturers have equipment undergoing conduction, convection or radiation. Cooling systems can keep the surrounding area safe for employees or prevent the machinery from overheating. A constant external temperature may also influence the company’s operations, such as how cooling mechanisms influence the power usage efficiency of data servers. The results depend on the heat transfer method and how the cooling process affects it.

Temperature Regulation Makes Equipment Last Longer

Industrial machinery functions may create more heat than desired. Combustion processes, friction and electrical resistance contribute to rising temperatures within and around heavy-duty equipment. The machinery may overheat faster if the surrounding environment doesn’t have a powerful cooling system.

Undergoing that experience continuously can weaken or deform components. Repairs might be necessary sooner than expected, creating downtime that sacrifices revenue. Paying for replacement parts and service appointments not covered by warranties is another financial drain on companies. Effective temperature regulation prevents those complications only if the machinery comes from leading providers.

Too Much Heat Endangers Employees

While the U.S. Occupational Safety and Health Administration (OSHA) doesn’t require air conditioning or heating units in workspaces, it recommends that employers maintain workplace temperatures between 68 and 76 degrees Fahrenheit. If production remains active around the clock, industrial environments may soar past that range and never cool down.

High-temperature industrial cooling systems ensure that workers remain in safe environments. They’re less likely to experience heat exhaustion, severe dehydration or heat-related injuries if their air quality stays at a comfortable temperature.

Most Important Cooling System Features

Business leaders and engineering teams learning about cooling systems should remember what makes each unit important. The key features define the air conditioning mechanisms leading the competition and effectively supporting workplaces.

Cooling Efficiency and Capacity

A chiller might remove heat effectively from a 10,000-square-foot warehouse, but it may not provide the same results for a 100,000-square-foot facility. Each unit has cooling capacity measurements describing the amount of heat it can remove in a limited period.

The data will also indicate which systems can handle the temperatures produced by high-intensity industrial equipment. Bigger units may be necessary for machinery producing triple-digit temperatures throughout everyday operations. Other options, like adding components to existing cooling systems, could also be preferred solutions. The best providers understand those needs and create cooling products accordingly.

Continual Monitoring Capabilities

Internet-connected devices make cooling systems more advanced. Internet of Things (IoT) sensors help industrial manufacturers become more efficient in numerous ways. They provide top-tier control and 24/7 monitoring of each coolant process. Facility teams can monitor each machine’s activity, pinpoint problems and get predictive maintenance tips for improved long-term use.

Engineers designing cooling machinery should implement advanced sensors connected with management system software to advance the temperature-regulation equipment. Continual monitoring benefits the teams relying on the systems. They understand how their facility is doing at any time. Meanwhile, supply chains could face less downtime because the manufacturing experts stay ahead of repairs or system malfunctions.

Scalability With Production

Industrial teams might have a specific quarterly quota one year and increase that goal the next. Consumer demand, shopping trends and tech advancements are a few factors that change production expectations. Cooling systems must scale with the manufacturer.

The technology should also be powerful enough to handle more intensive work schedules. Growing teams and higher demand may require longer schedules to meet production expectations. Companies maintaining intense operations may prefer cooling systems that come with ongoing maintenance services to accommodate their schedule.

Durability for Long-Term Use

Unplanned downtime costs an average of $150,000 per hour for small and medium-sized manufacturers. Large-scale facilities lose much more potential revenue. Cooling machinery must last for years under extreme temperature conditions and constant demand. Downtime for repairs costs significant amounts of money. The best coolant options will be durable and have warranties that ensure quick repairs in an emergency.

Understand the Best Cooling Systems for Industrial Facilities

Temperature regulation makes or breaks production facilities. Learning how the best cooling systems for high-temperature industrial processes work is the first step in understanding their role in the global supply chain. Anyone interested in engineering, manufacturing or cooling machinery should watch the leading providers to see how they provide the most significant benefits and reliable equipment in high-demand sectors.