Reciprocating Air Compressor is a positive displacement air compressor in which air is sucked in a chamber and compressed with the help of a reciprocating piston. It is called as positive displacement compressor because air is first sucked in a chamber and then compression is achieved by decreasing area of the chamber. The area is decreased by a piston which does reciprocating motion.

Working Principle

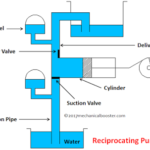

In reciprocating air compressor, as the piston moves towards the BDC, the air is sucked into the cylinder from the atmosphere and when it moves towards the TDC, the compression of the air starts and keeps on going and pressure increases. When the pressure increases upto its design limit it pushes the discharge valve to open and the compressed air is delivered to the storage tank.

Main Parts

- Piston: It does reciprocating motion in the cylinder and responsible for the compression of the air.

- Cylinder: It is a chamber in which air is compressed.

- Connection Rod: It connects the piston and crankshaft.

- Crankshaft: It is connected to the shaft of electric motor. And transfers its rotary motion to the piston.

- Suction valve: The air is sucked through suction valve when piston moves to BDC.

- Discharge valve: The compressed air is discharged through the discharge valve to the storage tank.

Working

The reciprocating compressor is either powered by electric motor, diesel/gas engines.

- As power is On, the electric motor starts rotating and also rotates the crankshaft attached to it. The piston starts doing to and fro motion inside the cylinder.

- As the piston moves downward (towards BDC), the air from the atmosphere enters into the chamber of the cylinder.

- Now the piston after reaching at BDC, starts moving upward (i.e. towards TDC), the compression of the air starts and its pressure begins to increase.

- When the pressure inside the cylinder increases above the pressure of the discharge valve, the discharge valve opens and the compressed air is delivered to a air storage tank from where it is utilized for the work.

Types of Reciprocating Air Compressor

- Single Acting

- Double Acting

- Single stage air Compressor

- Double stage air Compressor

1. Single Acting

In single acting reciprocating air compressor only single side of the piston is used for the compression of the air and other side is connected to the crankcase and not used for the compression.

2. Double Acting

In this types of compressor, both the sides of the piston is used for the compression of the air. When suction takes place at one side than compression is taking place at other side. Both suction and compression takes place on each stroke of the piston.

3. Single Stage

In single stage reciprocating air compressor the compression of the air takes place in a single cylinder. In the first stroke, it sucks the air from the atmosphere and in the second stroke it compresses it and deliver it to the storage tank.

4. Double Stage Reciprocating Air Compressor

In this types of compressor, the compression of the air takes place in two stages i.e. the air is first compressed to some extent in one cylinder and than it is transferred to the second cylinder for further compression. Finally the compressed air is stored in a tank.

This is the brief introduction about reciprocating air compressor – Main parts, working and types. If you find anything missing or incorrect than comment or mail us. If like this article than don’t forget to like and share it.