Have you ever noticed how we fill the air in the tires of our vehicles? Is there anything that helps to do that? Yes, we have air compressor to compress the air and then this air is used to fill tires of various vehicles. Air compressor has very wide application in various industries.

What is Air Compressor?

It is a device which compresses the gases to higher pressure and than this high pressure gas is used for various application like tire inflation, powering a turbine or used to do some mechanical work. The air compressor is generally powered by electric motor, diesel or gas engine.

Working Principle

Since we know that air is compressible and we only need some mechanical device to do that and for that we have air compressor. It takes air from one end and then squeeze this air to high pressure and deliver it to the other end for various application. There are so many brands of air compressor are available like craftsman air compressor, PORTER-CABLE Air Compressor etc. They all work on the same principle discussed above.

Types of Air Compressor

According to the Pressure Delivered

1. low-Pressure Air Compressors (LPACs): They can discharge pressure at 151 psi or less.

2. Medium-Pressure Air Compressors: It can discharge pressure in between 151 psi to 1000 psi.

3. High-Pressure Air Compressors (HPACs): they are having discharge pressure above 1000 psi.

According to the Type of Compression, It can be Classified as

- Positive Displacement : Piston type, rotary screw, rotary vane air compressor

- Dynamic Displacement: Centrifugal and axial flow air compressor

1. Positive Displacement Air Compressor

In positive displacement compressor, the air is sucked into a chamber whose volume gets decreased to compress the air. When the maximum pressure is reached in the chamber, the discharge valve opens and air is discharged to the storage tank. Once the pressure of the storage tank reaches to its desired upper limit the compressor stops. The compressed air in the tank is used to perform various works. As the pressure in the tank reaches to its minimum limit, the compressor again starts and begins the process of compressing air.

The positive displacement compressor can be of following type

1. Piston Type or Reciprocating Air Compressor

It is positive displacement compressor in which piston with connecting rod and crankshaft assembly is used to compress the air. The piston does the reciprocating motion in the cylinder and compresses the air.

Also Read:

- How Refrigerator Works ?- Easiest Explanation

- What is Positive Displacement Pump – Definition, Types and Working?

- Difference Between Rotary and Reciprocating Compressor

2. Rotary Screw Compressor

Positive displacement compression of air takes place in this compressor. It uses two helical types of screws matching each other, when it rotates it takes the air from the atmosphere and guides it to a chamber whose volume keeps on decreasing as the screw turns.

3. Rotary Vane Compressor

It is also a positive displacement compressor in which the rotor has blades. As the rotor rotates it traps the air in between the vanes (blades) and air gets compressed. A question hits now in our mind that How this air gets compressed by the vane compressor. Vanes of the compressor is adjustable according to the casing and the rotor in the casing is eccentric (i.e. it is not located in the center but its center is shifted away from the casing center). when rotor rotates, the air gets traped between two adjacent vanes. The casing of compressor gets on decreasing as the rotor rotates, and due to the decrease of casing the air gets compressed.

2. Dynamic Displacement Air Compressor

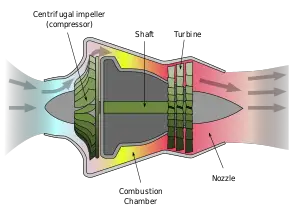

In dynamic displacement compressor, it has a rotating part which imparts its kinetic energy to the air and converts it into pressure energy. The impart of the kinetic energy is done with the help of the centrifugal force.

This type of air compressor includes centrifugal compressor and axial flow compressor.

1. Centrifugal Compressor

In this compressor centrifugal force is used to compress the air. It contains mainly three main parts i.e. impeller, diffuser and involute casing. It is the most commonly used type of air compressor in different areas.

2. Axial Flow Compressor

It is a compressor in which the air which is to be compressed moves axially during its compression. Axial flow compressor can continuously provide compressed gas.

Here we have learned about what is air compressor and its types. If you find anything missing then comment to us in the comment section. And if you liked this information then don’t forget to like share it.