Die casting decisions rarely start with the process itself. They start with a deadline, a tolerance stack, a cost target, and a part that has to perform. When that part sits inside a larger assembly, there is little room for variation. A small pore, a warped wall, or a weak thread boss can turn into expensive rework downstream. That is why many manufacturers look beyond internal capacity and build a supplier strategy that protects both quality and delivery.

Outsourcing can also unlock options you cannot easily build in-house, especially when you need speed, repeatability, and proven tooling support. For example, aluminum die casting in Malaysia often supports high-mix production and export-ready quality systems, making it attractive to companies that want stable output without expanding internal equipment, staffing, or maintenance demands. The key is outsourcing with intent, not outsourcing as a quick fix.

Access Specialized Expertise Without Hiring a Whole Department

Die casting is a craft backed by engineering. Gating and runner design, venting, shot profiles, and thermal balance inside the die influence porosity, flash, and dimensional stability. These details take time to master, and they require daily repetition to keep instincts sharp. Many in-house operations struggle because they run die casting as one function among many, rather than a core competency.

A specialized partner brings process engineers, toolmakers, and quality staff who work on the same problem set every day. That shows up in smoother launches, fewer surprises, and better root-cause analysis when issues appear. It also reduces institutional risk. If an in-house expert leaves, capability can drop overnight. A supplier team spreads knowledge across roles.

This is not only technical. It is organizational. Outsourcing gives you a built-in escalation path and access to learned best practices across multiple programs. You can still own the design intent, but you no longer have to own every process variable alone.

Reduce Capital Burden and Keep Cash Free for Product Growth

Die casting equipment is expensive, and the true cost extends beyond the machine. You need melting and holding furnaces, tooling, trimming presses, handling systems, dies, temperature control, and a maintenance plan that prevents downtime. You also need trained operators, safety programs, and spare capacity for peak demand.

Outsourcing turns much of that capital investment into a variable cost. That is useful if your product demand is uncertain, seasonal, or still ramping. Instead of buying capacity that may sit idle, you buy output aligned to real orders. This makes budgeting clearer and reduces internal pressure to “keep the machine busy” even when demand softens.

It also protects flexibility. If you later change alloys, revise geometry, or shift to a different manufacturing approach, you are not trapped by sunk equipment costs. You can pivot faster because your balance sheet is not tied to a single process cell.

Also Read:

- Difference Between Forging vs Casting

- Types of Patterns in Casting Process

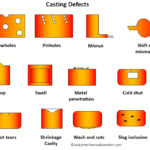

- What is Casting Defects – Types, Causes and Remedies?

Improve Speed to Market With Tooling and Launch Discipline

A die-cast part becomes “real” when the tooling is right. Tooling design, machining, polishing, and validation can dominate timelines. In-house teams frequently underestimate lead-time drivers such as cooling channel layout, die steel choices, and the trial loop needed to stabilize output.

Experienced die casting suppliers typically have a launch playbook. They run design-for-manufacturability reviews early. They flag risk zones like thin-wall transitions, deep ribs, and trapped air pockets. They also plan sampling, measurement routines, and process windows before production starts. That discipline can reduce the number of trial rounds needed to hit spec.

Outsourcing also helps when your project needs parallel work streams. While the tool is being built, the supplier can prepare fixtures, define inspection steps, and plan secondary operations. That parallel execution shortens the calendar without cutting corners.

Scale Up or Down Without Breaking Your Operation

Demand rarely grows in a straight line. A new customer contract can double volume. A market shift can cut it in half. In-house die casting lines handle this poorly because they are built around fixed capacity. When demand spikes, you need more shifts, more operators, more maintenance coverage, and sometimes more tooling. When demand drops, you are left with carrying costs.

Outsourcing gives you elasticity. A supplier can often scale by adding machines, shifts, or multi-site capacity, depending on the relationship and the part’s complexity. That helps you avoid bottlenecks that affect shipments and revenue.

It also reduces operational stress caused by constant rescheduling. When capacity is tight, internal teams often get stuck in firefighting. Outsourcing can shift that burden so your internal operations can focus on assembly, testing, and customer delivery.

Get Better Quality Systems and More Reliable Inspection

Die casting quality is not only about “good parts.” It is about consistent parts. That requires stable process control and inspection routines that catch drift early. A capable supplier will treat quality as a closed loop: process settings, in-process checks, dimensional measurement, and corrective actions tied to data.

Outsourcing can also improve access to advanced inspection methods. Many specialized suppliers invest in measurement equipment, porosity evaluation procedures, and capability reporting because these tools help them win and retain programs. For your business, that means clearer visibility into stability.

A practical benefit is documentation. Outsourcing partners used to serving export markets often provide tighter traceability, clearer inspection records, and more repeatable packaging and handling standards. That reduces downstream issues like cosmetic damage, mixed lots, and assembly fit problems.

Add Secondary Operations and Finishing Without Creating Complexity

Many die-cast components need more than casting. Trimming, deburring, drilling, tapping, machining, surface finishing, and cleaning can be required to meet functional or cosmetic needs. Running those operations internally adds scheduling complexity, additional vendors, and more handoffs where defects can be introduced.

A good outsourcing partner can bundle these steps into one controlled flow. That reduces touchpoints and keeps accountability clear. It also improves dimensional consistency because machining fixtures and casting references can be designed as a system rather than pieced together across suppliers.

Finishing is another place where outsourcing pays off. Coatings, anodizing, or painting processes require strict surface preparation and careful handling. When finishing is coordinated with casting and machining, the final part arrives ready to assemble, not ready to troubleshoot.