The laser cutter VS CNC machine are two technologies that stand out when it comes to cutting and making things with accuracy. Both technologies are very important in different fields, but they work in different ways and have their benefits. We’ll look at the features, uses, and how they compare to each other in this post. If you want to buy a cutting machine, it’s important to know which one would work best for you. We’ll also talk about what makes a top laser cutting machine maker stand out in a crowded market, like Yihai Laser.

What is a Laser Cutter?

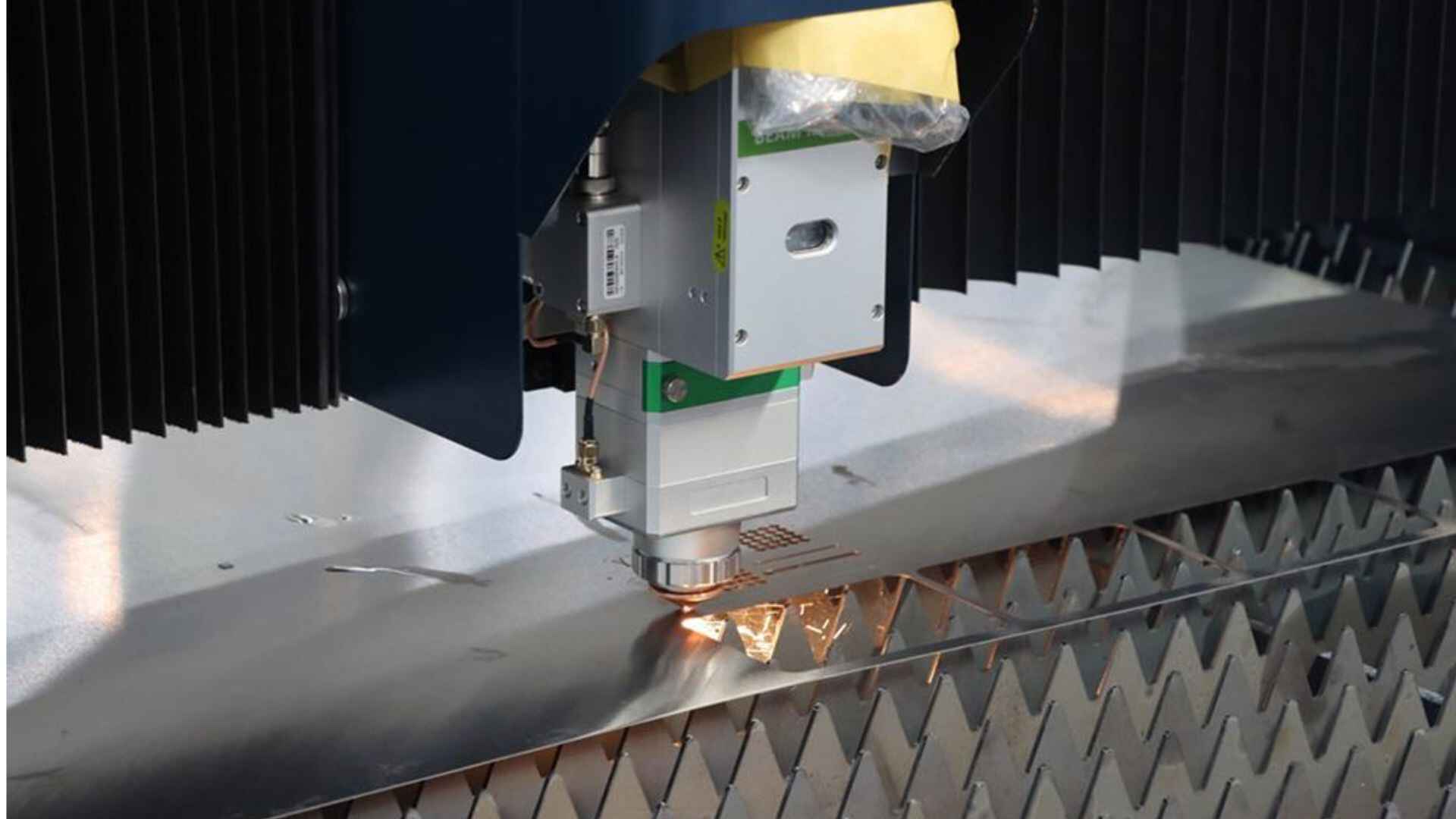

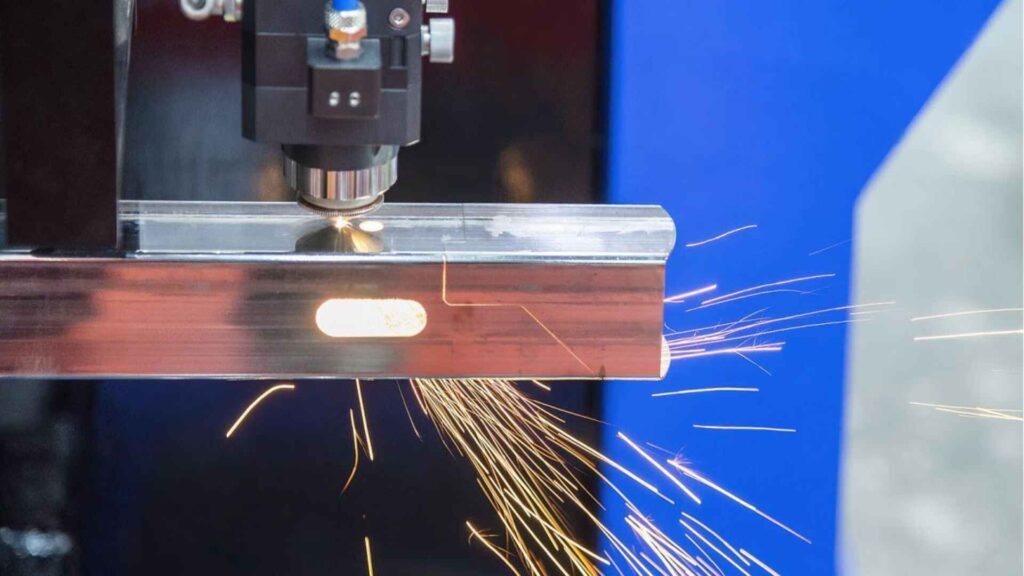

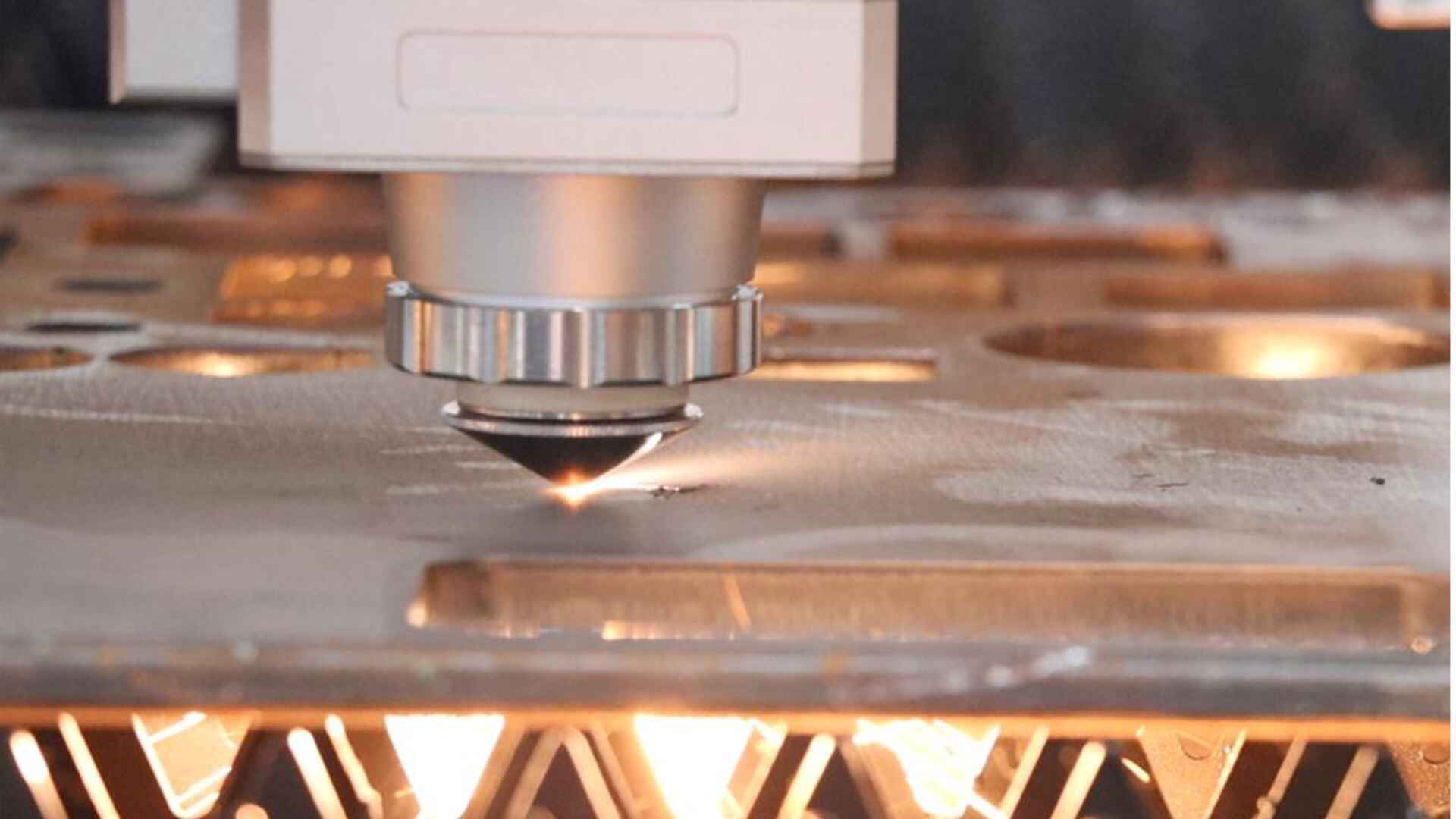

A laser cutter is used to cut materials such as metal, plastic, and wood using a beneficial laser cutter. Here, laser is focused at a position on the surface of the material. The high heat then liquefies, balls or gases the substance in a shape or pattern you desire. Laser cutting is known to be very accurate and easy to cut through thick and thin materials. It is also able to make clean smooth edges which means it is perfect in making detailed drawings.

What is a CNC machine?

CNC (Computer Numerical Control) machines, on the other hand, are automated equipment that do things like cutting, drilling, or milling by following instructions that have already been set up. CAD (Computer-Aided Design) software tells these devices how to move a tool along exact axes. CNC machines usually employ mechanical tools like drills or routers to cut through materials, which is different from laser cutting machine manufacturer. They can work on wood, plastic and metal among others.

Laser Cutter vs. CNC: The Main Differences

This is one of the greatest differences between laser cutter and CNC machine the method of material cutting. Laser cutters use light energy to make cuts, but CNC machineries use physical tools. A laser cutter results in a much cleaner cut when sitting through metal or any other product. The CNC machines however may have rough edges and require additional finishing.

The other common difference is the speed. Most jobs have laser cutters that are faster than the CNC machines especially when they need to cut thin materials. However, CNC machines are superior in a broad variety of jobs because they can handle more types of materials and thicker forms. The nature of the job will end up dictating which of the two machines is used at the end of the day.

Advantages of Laser Cutters

Laser cutters are used in many fields because they have several benefits. They are great for elaborate and complicated patterns since they can create very precise cuts. Laser cutters, such as cutting a big material or a small piece, are easy and fast. Also, laser cutting never touches the machine, and therefore, lasers do not wear out too easily, and hence the machine lasts longer.

Pros of CNC Machines

CNC machines are quite flexible. They are able to cut, drill, grind and even engrave 3D. Being applicable to so many things, they are perfect to serve as a solution to a wide variety of tasks, including prototype- and production-related. When dealing with thicker materials, CNC machines are especially useful since their mechanical tools can apply greater force. They are also quite good at making pieces that are very precise and can be repeated.

Deciding Between a CNC Machine and a Laser Cutter

When choosing between a CNC machine and a laser cutter, you should think about what you really need. An ideal approach can be a laser cutter in case you want to cut small materials within a very short time and with high accuracy. However, suppose you need a machine capable of performing many kinds of things, then a CNC machine might be your best bet as this machine can also be utilized in drilling and also in milling. Another factor to be put into consideration is the nature of materials that you would be working on and the degree of details that your projects would need.

How to Choose the Right Laser Cutting Machine Maker

Picking the appropriate laser cutting machine maker is very important to make sure you obtain good equipment that matches your demands. Yihai Laser is another company that is popular in the market and which produces high-performance laser cutters which are accurate and reliable. In case you require transformation of a machine to mass production or prototyping of any kind, a common firm of repute such as the Yihai Laser can ensure you make the right decisions and avail you the kind of support you would be in need of to derive the best results out of it.

Conclusion

Laser machines like cutters and CNC machines have advantages as well as disadvantages and therefore the most suitable for your needs is what will be the best. You should know the kind of machine that is good at as this can help you acquire one that best fits your needs in terms of speed, accuracy, variety, or even the ability to work with thicker materials. In order to find the best solution, one is also required to communicate with an already established laser-cutting equipment manufacturer such as Yihai Laser. Their good quality products and expertise will ensure that your business is not marred with problems.Visit Yihai Laser online at yihailasers.com where the latest laser cutting machines are available or just to find out more about us.