Flexible cables have significant utility, specifically for versatile and mobile robots. Mechanical engineering students must know which organizations to trust when they enter the field, and tenured experts must develop relationships with reliable enterprises to lay the foundations for the future of robotics. Discover the top-rated flexible conduits for robotics and automation projects.

Why Are Flexible Conduits for Robotics and Automation Necessary?

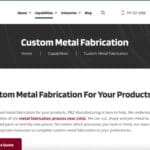

Cable conduits for robotics need to be flexible, especially given the high speeds and range of motion commercial machines require. The conduits ensure that the equipment stays operational for a long time without constantly being repaired or maintained. The fast-paced twisting and bending have to happen for demanding applications.

Automated machinery and robotics often operate without a human operator, so they need to be trustworthy. The tubes protect the delicate wires, preventing them from exposure to too many stressors, including moisture, heat, pressure and electricity.

Additionally, flexible conduits for robotics and automation are crucial because of safety codes and compliance. Cable management has specific requirements for environmental resistance and longevity. The materials, manufacturing and assembly of these components are crucial for making top-tier products.

1. AerosUSA

AerosUSA offers extensive technical expertise for cable enthusiasts of all skill levels, teaching them how to correct common conduit mistakes and level up their operations. It is also an online marketplace chock-full of protective products. Its stock has a massive range, including application-specific options for even the most niche jobs.

Every engineer browsing AerosUSA’s resources will be impressed with its depth for everything, including cable glands and accessories. Its custom engineering support is also a highlight, making it ideal for long-term partners for continuous support and improvement. The team’s decades of experience show, making it one of the most competitive on the robotics market.

2. ABB Group

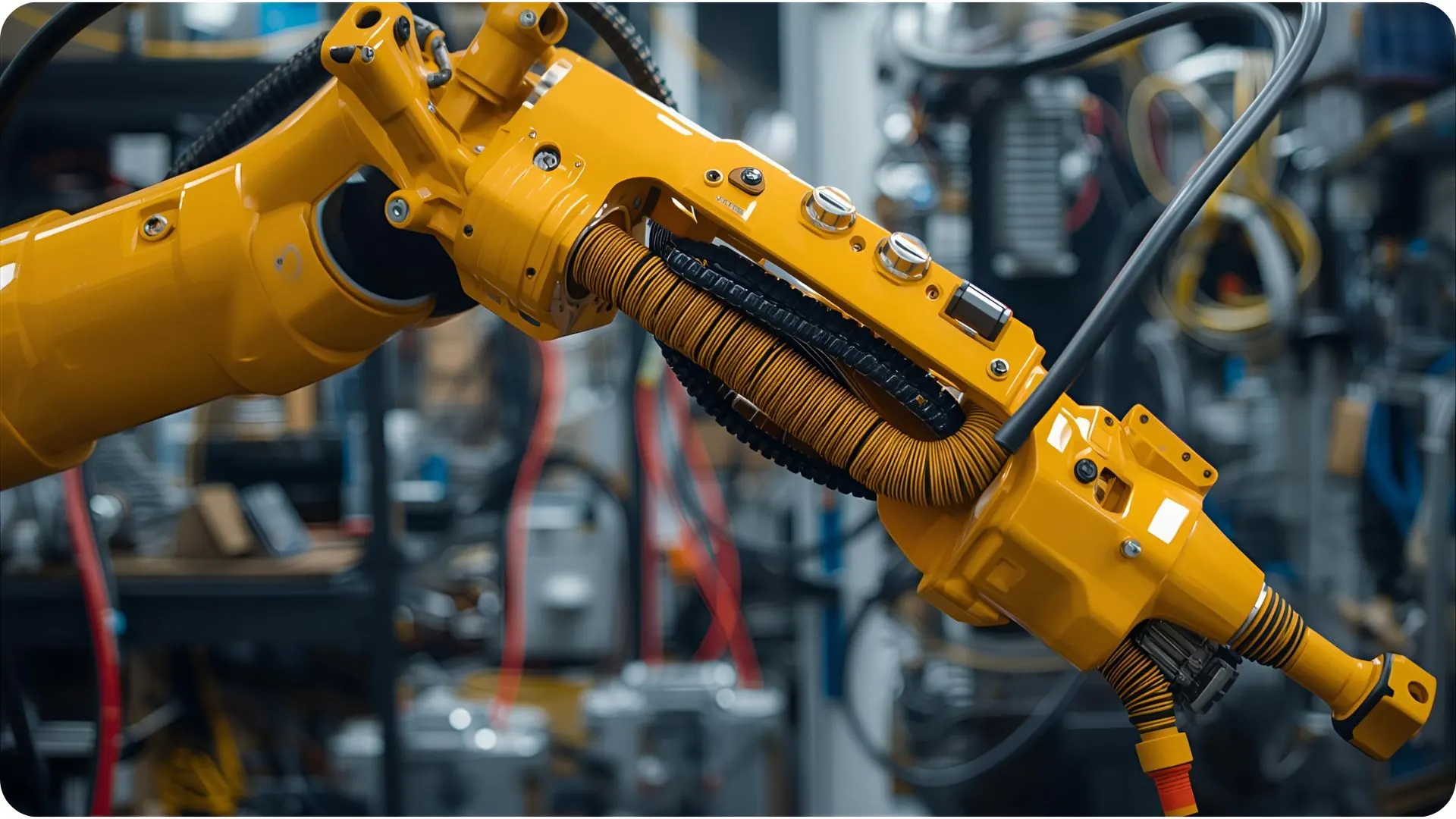

ABB Group has the most tenure on this list, and it shows with its special conduit designs, particularly for large-scale projects. It is known for its abrasion protection, ability to withstand torsional forces and flexible clamps to reduce mechanical stress. ABB Group has been around for over 140 years, generating $32.9 billion in revenue with its 170 global manufacturing sites.

The company has specialties in robotic processes and discrete automation, focusing on innovation and expansion to even more corners of the world. This kind of international presence only happens when the products are effective and dependable. Buyers can incorporate their conduits in everything from control systems to programmable logic controllers.

3. Igus

Igus began its journey into manufacturing in the 1960s by revolutionizing plastics. Now, its products are helping the flexible cable conduit landscape. They are Underwriter Laboratories-certified, representing the company’s rigorous quality testing. The business strives to make everything as cost-effective as possible while providing a four-year service life guarantee.

It offers an extensive selection of nearly 1,400 cable types and conduits to help almost any application, most notably its triflex R for robotics and other custom cable assemblies. Everything is meant to deal with the most intense conditions, including oil exposure and high speeds.

4. HellermannTyton

HellermannTyton was established in 1935 and has been a leader in cable management solutions ever since. Its primary services include flexible conduits and fittings, which are perfect for automation and robotics applications. Its cable ties and markers are also high-quality for industry purposes.

Because of its impressive global footprint, it offers some of the most reliable and fast deliveries. Searching through its sizable catalog is simple since buyers can sort conduits based on their priorities, including ingress protection rating and recommended use conditions. This eases decision-making, even for entry engineers.

5. FLEXA

FLEXA operates out of Germany and has been helping the sector for over 75 years. It has metal and plastic conduits for more mobile and stationary robotics. Every product prioritizes defenses against harsh environments, making them adaptable and reliable for the most intensive sectors, like chemical production.

It has worked in many sectors, including rail vehicle construction and energy, so it knows exactly how to fashion products for all use cases. The company’s expertise is demonstrated through its many resources and videos on how to choose the right conduits, what’s next in 100% recyclable products and many other subjects.

6. Anamet Electrical, Inc.

Anamet Electrical has created some of the most liquid-tight flexible cable conduits available. For automation and robotics, this is essential because anything from lubricants to water and oil could sneak into the system. Preventing this is crucial, and Anamet wants to provide this peace of mind.

Its conduit options have countless desirable qualities, including antistatic properties, the ability to withstand extended ultraviolet exposure, multiple classifications in hazardous locations and high electromagnetic shielding. The team also collaborates with many electrical groups to continuously improve its wiring protection methods, showing a willingness to share knowledge.

7. Panduit

Panduit is another global player in the cable conduit game, focusing on industrial automation, data centers and cable management. Its team is primed for facing the needs of digital infrastructure development because of its dedication to the Industry 4.0 movement early on. Panduit has earned numerous industry accolades, making it a known industry thought leader and pioneer for research and development.

One of its star products is the StrongHold cable conduit, which promises ease of installation and tidy operations. For some models in the range, the clamps enable 360-degree movement, which helps manufacturing plants get the most out of their production robots.

Provider Overview of Cable Conduits for Robotics

Compare each provider and their unique value propositions and experience.

| Company | Specialization | Experience | Noteworthy Quality |

| AerosUSA | Robotics cable conduits | 20+ years | Technical how-to guides and personalized engineering |

| ABB Robotics | Automation | 140+ years | Global reach and integration |

| Igus | Motion plastics and energy | 60+ years | Low-maintenance products |

| HellermanTyton | Cable management | 85+ years | Worldwide manufacturing accessibility |

| FLEXA | Robotics protection | 75+ years | Extreme environments |

| Anamet Electrical, Inc. | High IP-rated conduits | 70+ years | Heavy industry focus |

| Panduit | Infrastructure problem-solving | 65+ years | Industry 4.0 focus |

Depending on a buyer’s priorities and goals, other qualities of these organizations to consider include:

- Sustainability initiatives

- Ethical material sourcing

- Availability of educational resources and training

- Customization options

How to Determine the Best Providers

Finding the top-rated flexible conduits for robotics and automation projects requires specific criteria. Each company must exhibit these qualities to justify industry standing and reputation as a high-quality supplier.

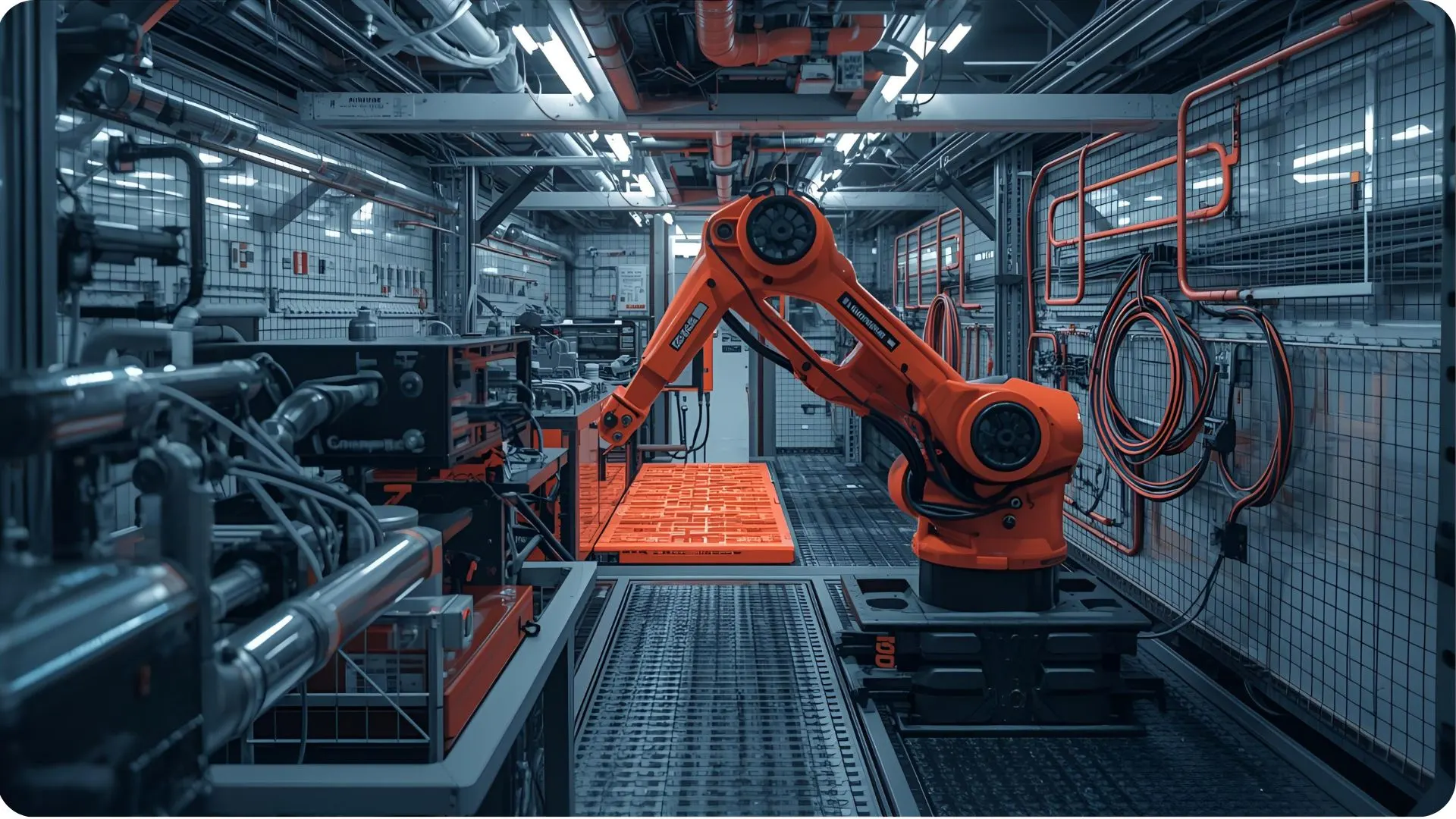

Ability to Withstand Continuous Motion

Flexibility is a sign of durability, allowing the conduit to endure lots of wear and tear from being pulled and bent in all directions. Robots like pick-and-place arms move so rapidly that their components must be able to keep up with their momentum and force. If a cable is too stiff to accommodate torsional stress, it will not last long in manufacturing environments.

Mechanical Strength

Mobility is important, but the conduits should be able to deal with a lot of physical weight and pressure against external forces, too. Abrasion from chemicals and weight from metals are only a few things the piping needs to push against.

Ingress Protection (IP) Ratings

IP ratings represent how few openings there are in the conduit for outside influences to enter. The IP rating should prove that water, dust and other debris can’t enter. Without noninvasive inspection methods that can see through the conduit, operators won’t know what gets inside. Quality IP ratings lower the need to perform these reviews or worry that adverse influences have impacted the wires inside.

Accessible Installation and Management

Installing the conduits and maneuvering the cables should be straightforward. They should be easy to lay and manipulate so the area remains clutter-free. Replacing them should be just as simple, with a plug-and-play quality that makes them quick to fix.

FAQ About Cable Conduits for Robotics

There is more to cable conduits than meets the eye, so learn the answers to the most prominent queries.

1. How Do You Run a Cable Through a Flexible Conduit?

Here are the simplified steps for handling a flexible conduit for a robot:

- Place junction boxes.

- Ensure everything is compatible and the correct size.

- Prime the cable for installation with lubrication and flexibility testing.

- Use a vacuum or other pulling method to drive the pilot string through the conduit.

2. How Do You Fasten a Flexible Conduit?

Fasteners and fittings are the best way to ensure a secure robotic cable conduit. They should attach at the ends and be compatible with any junction boxes or panels they connect with. Technicians can also employ clamps and other security mechanisms to be on the safe side.

3. When Should a Flexible Conduit Be Used?

Robotics and automation tools are the primary applications for flexible cables. However, other industries with many moving parts and constant turnovers for different process orders may also benefit from their malleability.

The Top-Rated Flexible Conduits for Robotics and Automation Projects

The most reliable companies exhibit all these qualities while providing resources for customers applying them in the most productive way possible. Robotics is still a growing sector, so there is plenty of room for all related sectors to grow. The cable and conduit makers of the world must look ahead to prepare for what’s next, just as their customers need to build connections and collaborate with top performers to design the most optimized machinery.