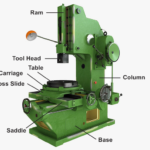

Holemaking is one of the most common CNC machining operations performed by machinists. A series of machining processes drill a hole into a workpiece. The machining stage is a material removal phase that builds features on the workpiece by cutting off redundant material. This process involves a machine, cutting tool, fixture, and workpiece.

Guide to Holemaking Tools for CNC

Here are several tools employed to perform the holemaking process on a workpiece and the levels of precision they offer –

Twist, Spot, and Center Drills

Twist drills are hugely popular approaches when performing holemaking on a workpiece. They come in different sizes, including Metric, Imperial, and special sizes, which include numbers and letters. Twist drills are also available in various materials, such as Cobalt, HSS, and Carbide. The market offers drills of different lengths, including jobber lengths and the screw machine.

Some machinists prefer interpolated holes over drills since they come in several lengths and help make holes of larger sizes which leads to more savings. Interpolated holes offer specialized holemaking in cases where precision is the top priority. However, twist drills are faster in removing material than end mills, with all other parameters being leveled out.

Also Read:

- What is CNC Machine – Main Parts, Working, Block Diagram

- Different Types of Milling Cutters Used in Machining Process

- The Different Types of CNC Machines and What They are Used For

Interpolated Holes/Helical Milling

Interpolated holemaking is also a relatively common process amongst machinists with experience. An endmill traverses a spiral/circular pattern to drill a larger hole size than the endmill.

CNC machines used to achieve helical milling have the competency to create holes of arbitrary size via an endmill that traverses a helical path. The end mill enjoys three significant perks in contrast to a twist drill –

- One endmill size can make infinite hole diameters, considering they are identical in size or greater compared to the endmill. Endmill frees up slots on the tool changer, helps save tool changes, and provides higher efficiency.

- The end mill can drill flat bottom holes. You can also generate special twist drills for those bottom holes.

- Interpolating a hole is often time-consuming but consumes relatively less power than performing twist drilling on a hole of equivalent size.

Boring Heads

While drilling, reaming or interpolating a hole are the most common practices, boring heads come into play when you wish to create larger holes with tight tolerances. Boring heads also enhance the finishing of the wall surface.

A typical scenario where a boring head might be preferred over other approaches would be machining a bearing pocket with tight tolerances. However, some instances of trial and error are involved when checking for the cutting depth, often performed to bring the bore within tolerance. This hit-and-trial approach can make boring bars an expensive procedure.

While boring heads deliver tight tolerances, installing and operating one can get time-consuming, which is why they are only employed for the most demanding scenarios. Opt for interpolation if you are short on time since it also offers high accuracy levels.

Reamers

Reaming is a cutting process that employs a reamer (a special tool) to expand the size of an existing hole to reach a specific diameter and render a smooth finish on its side walls. Reaming is performed on a lathe machine, milling machine, or drill press.

If you require hole diameter tolerances tighter than +/- 0.002″, opt for a reamer to get the job done. You must also note that the surface finish post reaming varies depending on the workpiece material.

Reamers are swift and efficient when cleaning up the hole sides, ensuring its roundness, and helping achieve a specific diameter with high accuracy levels.

Reamers do not change the hole’s location but often feature long shanks that show slight deflection to ensure they enter the hole. These shanks help improve the finish quality of the surface and alter the hole size without hassle.

Counterbores and Countersinks

Counterboring and countersinking provide unique treatments to allow the bolt’s top to be recessed below the material’s surface. A counterbore comes in a cylindrical shape and has a wider diameter relative to the hole’s bore, while a countersink has a conical shape.

Considering the conical shape of countersinks, a special tool is required with the appropriate angle to cut the conical section successfully. In specific cases, it is preferable to opt for a spot drill to countersink, provided that it has the correct angle and will serve for spotting.

Besides that, if you have specific requirements, consider investing in a special countersink to get the job done. You could also opt for a combination of twist drill and countersink or countersink collar for your twist drills.

If you wish to avoid the hassle, you can conveniently interpolate counterbores with an endmill instead of employing a counterboring tool to get the job done.

Final Words

Holemaking tools come in an extensive range, such as drills, countersinks, reamers, boring heads, and more, all of which serve unique purposes. These tools drill holes at varying speeds and accuracies and offer special perks such as refined surface finishing, creating special features, and others. Go through the various holemaking processes mentioned above to decide which one serves the best use case for your workshop.

About the Author:

Peter Jacobs

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights to various blogs on CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.