Welding a car is a fantastic experience. Modifying, creating, and reattaching parts of the automotive is a thrill like no other. Hobbyists and professionals alike enjoy the experience of creating an automotive with their bare hands. For a perfect weld, you would need a good quality welding machine, a welding coat and gloves, and a welding helmet to start.

Rusting and cracks on car bodies are usually easy to fix but are often overlooked by most people. These tasks are considered time-consuming and are also thought of as costly. However, welding at home will help reduce the cost and save your car. Most home welders start with small things around the tool shed like fixing old metal cupboards, metal garage doors, wire fencing around the property, and window grilles. Once you get the hang of handling the welding machine, you can start welding the car for broken metal parts to be mended, rust removal, and joints’ strengthening.

Let us help you with some helpful tips with automotive welding for beginners. We understand you may have several questions, and we will try to give as much information as possible.

What is Automotive Welding?

Automotive welding is the bodywork welding of a car or automobile. This welding is done to repair cars and fix issues related to strength and longevity. Service centers always weld cars to repair rust and other issues before putting a fresh coat of paint.

Since welding uses exceptionally high heat to fuse metals, the process is intricate and takes some patience and skill. Things like rusted metal parts, cracked panels, and damaged hoods and fenders are easily fixed with welding.

When Do You Need To Weld?

Large structural jobs and bodywork require automotive welding. Car owners usually face rusty patches, cracked panels in the engine compartment, loose doors, cracked mufflers, cracked chassis, or a puncture in the car’s boot. These repairs can easily be fixed with a good quality welding machine and a little patience. Car owners who weld their own cars usually end up saving massive amounts of money in the long term.

Automotive spares are pretty costly, and if the car is old or out of warranty, the service centers may charge a considerable sum to repair the vehicle. Carefully welding the parts together and strengthening the car will make it last longer, cost less in the upkeep and maintenance, and will give you immense satisfaction.

Welding the automobile together will also allow you to understand your car and drive it better. Accomplishing simple tasks will become easier with time, and your car will start running better. If the panels are rusted, you can patch them instead of replacing them and put a fresh coat of paint to make your car look new again.

Also Read:

- Top 5 Best Blind Spot Mirrors for Car

- Laser Beam Welding – Definition, Main Parts, Types, Working, Advantages and Disadvantages

- What is Powder Coating – Definition, Working, Types, Advantages and Disadvantages

What Are The Different Types Of Automotive Welding?

Welding of different parts requires different welding methods. The three common types are MIG, TIG, and Stick welding.

- MIG Welding: Metal Inert Gas (MIG) welding is a popular type and uses a gas and filler material fed through a wire that is part of the welder. This type of welding machine is easy to use since it helps with one hand. MIG welding machines are great for bodywork repairs and have an excellent output.

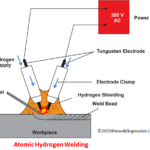

- TIG Welding: Tungsten Inert Gas (TIG) welding uses a tungsten electrode to create a weld. Welders need to use both hands to operate this machine. It is used for advanced and refined jobs and is excellent for aluminium, stainless steel, and thin sheets of metal.

- Stick Welding: Shielded Metal Arc Welding is used for heavy metals like iron and steel. It is not commonly used since there are likely to be errors due to cracking and weld spatter.

Basic Tips:

- Always Use The Proper Tools: Welding is not child’s play. It should only be done with the correct tools. Some of the tools and safety equipment include the welding machine, welding curtains, angle grinders, locking welding clamps, body hammers, sheet metal gauge, welding clamps, leather welding gloves, welding coat, and so on.

- Maintenance: Never ignore the maintenance and upkeep of tools. Regular safety checks ensure that the machine tools will not have unnecessary emissions, leakage, and voltage fluctuation. Keeping the equipment clean will lengthen the lifespan and yield excellent results every time.

- Practice: Welding requires patience and practice. Starting without examining the tools can lead to severe injury or death. Always practice on other pieces before starting on expensive cars. Welding takes time and should be done slowly and carefully.