If you’ve ever tried restoring a vintage car, you already know the struggle: rusted brackets, grimy engine parts, caked-on coatings, delicate sheet metal, and components that are nearly impossible to replace. Traditional cleaning and welding methods often remove too much metal or distort original parts—both dealbreakers when authenticity matters. Today, that’s where laser-based tools begin to change the game.

Whether you’re reviving a classic muscle car or preserving a rare collector model, technologies such as laser cleaning and the modern laser welder are giving restorers safer, more precise ways to preserve original components. These tools bring manufacturing-level precision into restoration workshops, offering non-abrasive cleaning, distortion-free welding, and a workflow that respects a vehicle’s historical integrity.

Laser Cleaning: A Gentle but Powerful First Step in Restoration

What Laser Cleaning Is and How It Works

Laser cleaning uses a pulsed fiber-laser beam that targets rust, old coatings, carbon buildup, oil, and paint without physically touching the part. Contaminants absorb the laser’s energy and instantly convert into vapor or plasma. Meanwhile, the base material—whether aluminum or steel—reflects most of the beam, protecting it from overheating or abrasion.

This selective reaction is what makes laser cleaning uniquely suited for delicate, thin, or historical metal surfaces.

If you want to understand how metal cleaning compares with other surface-prep methods, also read:

What is Powder Coating – Definition, Working, Types, Advantages and Disadvantages

Key Benefits of Vintage Car Parts

A major challenge in restoration is removing contaminants without harming the original metal. Laser cleaning excels because it:

- Removes rust, scale, carbon, grease, and coatings without abrasion

- Preserves stamped markings, casting textures, and original tolerances

- Requires no harsh chemicals or blasting media

- Prevents thinning or rounding off edges

- Reaches into tight corners and complex engine geometries

- Reduces dust, noise, and messy cleanup

When you’re working with 40- or 60-year-old parts that may never be manufactured again, this level of care matters.

Typical Applications

Laser cleaning is often used for:

- Chassis and frame rails

- Suspension brackets and control arms

- Engine blocks, heads, and mounting points

- Brake components and fuel-tank areas

- Body panels with flaking paint or spot rust

- Pre-weld surface preparation

- Preservation of original casting details

It allows you to clean parts thoroughly while minimizing the risk of accidental damage.

Laser Welding: Precision Repairs That Respect Original Integrity

What Laser Welding Is and Why It Helps Restorers

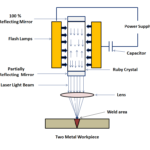

A laser welder concentrates heat into an incredibly narrow, controlled beam. Instead of heating a large surrounding area—as traditional MIG or TIG welding does—a laser delivers deep penetration with minimal surface spread. That means you can repair thin, fatigued, or complex components with far less warping.

If you want to deeply understand how laser welding works, check this detailed guide:

Laser Beam Welding – Definition, Working, Applications, Advantages

Benefits of Over-Traditional Welding in Restoration

Laser welding gives you advantages that traditional methods simply can’t provide when dealing with thin sheet metal or rare parts:

- Maintains original dimensions and geometry

- Causes minimal distortion due to low heat input

- Produces clean seams with almost no spatter

- Reduces grinding and finishing afterward

- Safely welds thin or mixed-metal joints

- Preserves the metallurgy and structural integrity of old parts

For restorers who value authenticity, this is crucial.

To learn the basics before advancing to laser welding, here’s a helpful guide:

Automotive Welding for Beginners – Basic Tips

Use Cases in Vintage Restoration

Common laser welding applications include:

- Repairing rusted frame sections without altering alignment

- Adding patches to body panels or floor pans while avoiding ripples

- Reinforcing brackets or housings

- Repairing aluminum or mixed-metal assemblies

- Strengthening structural areas without excessive heat distortion

It allows you to keep original metal wherever possible—one of the core goals in professional restoration work.

Combined Laser Workflows: Cleaning + Welding for Best Results

Laser Cleaning Before Welding

Laser cleaning creates an ideal pre-weld surface. Removing rust, oxide, and paint improves weld penetration, reduces contamination, and prevents porosity. You end up with stronger, cleaner, longer-lasting welds.

If you’re new to welding safety and want to stay protected during the process:

Top 5 Best Auto Darkening Welding Helmet

Laser Cleaning After Welding

Post-weld laser cleaning can remove residue, oxidation, and discoloration without:

- Over-grinding

- Changing the metal thickness

- Damaging original features

This is especially helpful for visible or cosmetic areas.

Preserving OEM Details

Vintage vehicles often have stamped codes, serial numbers, or casting marks that confirm authenticity. Laser tools help maintain these details by avoiding aggressive grinding or blasting that could erase them.

Advantages of Laser-Based Restoration vs. Traditional Methods

Protection of Metal Integrity

Laser tools are non-abrasive and precise. They preserve:

- Original thickness

- Surface textures

- Fine details

- Factory metallurgy

For restorers trying to keep vehicles as original as possible, this protection is priceless.

Time, Labor, and Cost Savings

Laser technology dramatically reduces labor time:

- Faster cleaning than sanding or blasting

- Less time spent masking or protecting edges

- Minimal post-weld finishing

- Smaller mess and no need for chemical disposal

These efficiencies free up time and resources for more detailed restoration tasks.

Environmental and Safety Benefits

Laser systems create no chemical waste, toxic fumes, or abrasive dust clouds. They are safer for the operator and far cleaner for the workspace.

Challenges and Limitations to Consider

Initial Investment

Laser systems cost more upfront compared to traditional tools. While long-term savings are significant, small hobby shops may find the initial purchase challenging.

Material and Surface Constraints

Laser tools may struggle with:

- Deep, layered rust

- Heavy pitting

- Very thick structural steel beyond beam penetration

In those cases, mechanical repair may still be needed.

Operator Skill and Safety

Although user-friendly, laser tools require proper training in:

- Beam focus

- Parameter settings

- Eye protection

- Ventilation and extraction

Good technique is still essential for quality welds and safe operation.

To explore more restoration tools and safety equipment, you may also like:

21 Must-Have Tools for Home

Their Role and Modern Laser Welders in Car Restoration

Modern restoration increasingly relies on tools that respect original integrity while offering precision and control. Companies like Denaliweld provide laser welding systems designed to meet these needs—offering clean seams, consistent penetration, and the versatility required for delicate vintage car repairs. Their solutions help you restore original parts instead of replacing them, maintaining the authenticity that collectors value.

Conclusion

Laser cleaning and welding have revolutionized the restoration of classic vehicles. By removing contaminants without abrasion and repairing metal without distortion, these technologies let you preserve more of the original car while achieving stronger, cleaner, and more accurate results. When combined, laser cleaning and a modern laser welder create a workflow that delivers efficiency and protection in equal measure. As more restorers adopt these tools, the future of vintage car preservation becomes brighter—safer for the metal, more authentic for enthusiasts, and more efficient for workshops committed to craftsmanship.

FAQs

Laser cleaning is a non-contact process that removes rust, grease, paint, and contaminants using a pulsed laser beam without damaging the original metal. This makes it ideal for vintage or delicate car parts.

No. Laser cleaning selectively removes surface contaminants while reflecting off the base metal, preventing abrasion, thinning, or distortion.

Laser welding uses focused heat, resulting in minimal distortion, deeper penetration, and cleaner welds compared to MIG/TIG, especially important for thin or rare car parts.

Laser cleaning is excellent for surface rust, scale, paint, and carbon buildup. However, deep pitting or heavy rust layers may require mechanical repair in addition to laser treatment.

Yes. Laser welding applies heat very precisely, making it safe for thin sheets, fragile components, mixed-metal joints, and parts that would warp under traditional welding.

By removing rust, oxide, oil, and paint from the weld zone, laser cleaning enables better weld penetration, reduced contamination, lower porosity, and cleaner weld strength.

Yes. Laser welding works efficiently with aluminum and mixed-metal assemblies, producing clean, distortion-free joints ideal for restoration work.

Laser cleaning is non-abrasive and does not remove base metal, while sandblasting can thin metal, erase casting marks, and damage delicate parts.

Key limitations include high initial cost, the need for operator training, and limited performance on deep rust or very thick steel.

Yes. Laser systems produce no abrasive waste, no chemicals, and minimal dust, making them cleaner and safer for workshops and operators.