Because of its adaptability and strength, sheet metal is vital to the functioning of many branches of industry and sectors – machinery, consumer electronics, aviation, transportation, industrial machinery, appliance manufacturing, among a few.

And not that long ago, it would have been relatively expensive for most businesses to engage in outsourcing metal sheet components and final products. But as technology advanced and sheet metal building products became widely available, things changed.

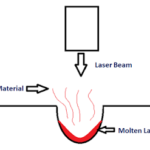

Nowadays, sheet metal fabrications are produced with a wide variety of forming processes such as: bending, curling, deep drawing, expanding, hemming and seaming, incremental sheet forming, ironing, laser cutting, perforating, press brake forming, punching, roll forming, rolling, spinning, stamping, water jet cutting and wheeling, to be more precise.

Additionally, different kinds of metals are used to make sheet metal, such as aluminum, copper, steel, brass, titanium, nickel, etc. Depending on the thickness, they are generally divided into two groups, heavy plate, and thin gauge. In other words, there are so many different options for sheet metal fabrication techniques, materials, and fabricators on the market that the selection process might be overwhelming even for experienced industry professionals.

As you set on a mission to find the appropriate type of materials that suit your needs, you need to consider several elements. The most important being weight, size, and look. So we would definitely urge you to ask someone involved in the industry for advice. They can be of great assistance when choosing your materials.

Besides, as the markets expand, a significant number of companies specializing in sheet metal prototyping offer a wide range of options for you to develop a fully-functioning prototype before you engage in mass-production of the specific part. Here’s how to find the best metal sheet products and services on the market.

Also Read:

- What is Lathe Machine? Main parts, Operations and Working

- What is Slotter Machine – Parts, Types, Working, Operations, Advantages and Disadvantages?

- What is Electrical Discharge Machining (EDM) Process and How it Works?

Carefully Choose From the Different Material Finish Options

Metal that has been galvanized and then polished on top of another metal is an excellent choice when looking to produce galvanized goods. As the commodity still maintains the properties that make it resistant to corrosion, it is widely referred to as ‘curing steel’. Generally, this type of steel is much cheaper than others, but it can also be very costly if you are not careful in the negotiating phase.

Other than galvanizing metal sheets, there are also numerous other finishing options available for sheet metal products including bead blasting, plating, powder coating, anodizing, and other custom finishes.

Conduct Thorough Online Research To Find The Best Supplier

Nowadays, conducting thorough online research is vital in many purchases that you make for your business, and an excellent online search for your next sheet metal product is no exception. In the digital age, every viable market research encompasses good, thorough online research.

Remember to specify your search to specific labels depending on the type of sheet metal building you need. This will peg down the companies which would be suitable for you. After you picked your enterprise, call them, and request information about their return and shipping practices.

Appropriate shipping arrangements could be a difference-maker in cost-effectiveness. Many B2B companies today ship at their own expense and can deliver the requested product to your door. You can easily access their prices, payment policy, and other information on the company’s website.

Next, take a close look at the customer reviews. Online reviews are critical to customers today, so companies will go out of their ways to get as many good reviews as they can. Subsequently, they hope there will be no bad ones. Bad customer reviews are a common sign that you should look to the next company.

Also Read:

- Ultrasonic Machining (USM) – Main Parts, Working Principle, Advantages and Disadvantages with Application

- What is CNC Machine – Main Parts, Working, Block Diagram

- 37 Types of Hammers that You Don’t Know?

However, many people feel more comfortable talking directly to the company when buying, so feel free to make a phone call to their agent. The phone number will also be easily found on their website. It’s important to keep in mind that a low price doesn’t necessarily mean a good deal. It is critical to secure a strong, lasting, quality material (and, of course, acquire it for a reasonable price) to guarantee a favorable result, so don’t get carried away by cheap options.

If you do good online research, you will almost certainly gather information on all the prices available to make the right decision.

Pinpoint The Type Of Premium Sheet Metal Product That Checks Your Boxes

Before embarking on any research for a dependable supplier, you need to know your side and identify what kind of premium metal sheet product is right for you. Many options are available, including nickel, aluminum, stainless steel, brass, zinc, and copper.

Speaking of thickness options, there is a variety of gauges available. Make sure to point out the exact type of premium sheet metal product that’s suitable for your needs before you place any kind of order.

Only Work With Reliable And Certified Partners

When you establish this, it is time to start looking for a manufacturer that can provide it. After you pinpoint the company that offers the best products suited to your needs, do a background check on its name and standing in the market. Ask for necessary certifications if applicable.

Recognized certifications are not a game-changer by themself, but companies that do possess them in most cases have a better reputation and more experience, which is very valuable when shopping for premium metal products. You need to make sure you are getting your money’s worth.

Final Words

Choosing the right type of sheet metal product can be a tricky business. Still, it can be extremely beneficial to your construction project if you are careful in the process. A large pool of enterprises offer these services today, so allow yourself to invest some time into well-rounded research and double-check all the prices and conditions.