Are you looking for information about the drilling machine? Well, we use the drilling machine in almost all daily as well as many outdoor applications. Inside this article, we are going to discuss the drilling machine, features, advantages and all other interesting information.

What is Drilling Machine?

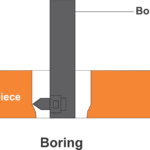

A machine which is used or the drilling holes in various application is called a drilling machine. Drilling is a process in which we remove the material from a workpice with the help of a drill bit. A drill bit cuts the hole of circular cross-section in solid materials. The size of the drill bit varies as per the application. The size of drill bits is measured in terms of diameter.

History Behind the Drill Machine

William Brain and Arthur Arnot invented the first electric drill in 1889. Later in 1895, Wilhelm Fein discovered the first portable electric drill machine.

After talking about the history and learning the definition of the drill machine, let us take a glance at the main parts of the drill machine.

Main Parts

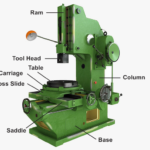

1. Column:

The column is a major component of the drilling machine. We can say that it supports the drill machine and all other its parts such as table, arm, spindle, Electric motor for power transmission etc.

A column consists of a long rod generally made up of steel. The column and the table are perpendicular to each other. That means the column on the table makes a 90º angle with the table on which it is kept.

Also Read:

- Types of Lathe Machine – Mother of all Machines

- What is Milling Machine – Operation, Parts and Types.

- Difference Between Capstan and Turret Lathe

2. Spindle:

The spindle is another important part of the drilling machine. The spindle is used for holding the tool and it also helps us to rotate the tool. At the bottom of the spindle, a chuck is located. An arm is placed which holds the spindle in its position. These are connected to the column.

We can use the spindle return spring for moving the spindle up and down easily. For the better functioning of the drill press, the weight of the spindle matters a lot.

3. Base:

The base is used for supporting the column and making it stable. Generally, the base is made up of steel or iron.

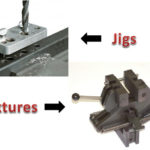

4. Drill jigs:

Have you ever heard of the drill jigs before? They are mainly used in multi-tasking.What you do if you want to make many holes in one particular direction? For making many holes in one direction, drill jigs are used. Drill jigs keeps the drill bits firm and they help them in going in a straight direction along with the drill bushings,

5. Work Table:

It is used to hold the workpieces to be drilled. The worktable can be moved up or down depending on the application. If you want to drill at some higher positions then, simply move your work table up.

Worktable also has T slots, holes and other useful structures that can be used for holding workpieces in any application related to the drill machine.

6. Power Transmission:

In the drilling machine, power is supplied from the electric motor. The v-belt and the pair of spulley stacks help in the power transmission. Pulley stacks are used for monitoring the speed of the spindle.

Types

It can be divided into many types considering various factors. Here are the main types:

- Portable /Hand Drilling Machine

- Sensitive Drilling Machine

- Upright Drilling Machine

- Radial Arm Drilling Machine

- Multi-spindle Drilling Machine

- Gang type drilling machine

- Numerical Control Drilling Machine

Apart from the above drilling machine types, there are many other machines available. You will require a particular drilling machine as per your requirement.

Working

- The spindle of the drill machine is connected to the electric motor with the help of a V type belt and stepped pulley.

- As the power is ON, the electric motor starts rotating and it also rotates the spindle. The spindle has drill bit of particular diameter rotates at high speed with the spindle.

- A rotating drill bit is brought near the target location to make a hole in the workpiece.

- During the drilling operation, a Sufficient amount of force is applied on the spindle through a hand Feed to increase the depth of the hole in the workpiece.

- After the hole is produced, the electric motor is shut off to stop the process.

- In some cases like drilling holes in metal, lubricant (oil or water) is used to prevent the heat produced.

Advantages

- It is capable of making permanent long holes.

- Drilling machine can be used for marking the ends of the components.

- Almost every industry used the drill machine for most of their applications.

Disadvantages

- Sometimes we cannot use drilling machine in complicated applications.