During the casting of metals in the foundry shop we use sand for the preparation of mould. It is the moulding sand properties which improves the quality of the casting metal. If sand of suitable property is chosen, then it greatly minimises the casting defects that may be produced during the mould preparation and casting. In this section, we will discuss all the properties of moulding sand that it must possess for the preparation of excellent mould cavity.

Properties of Moulding Sand

Moulding sand should possess the following 6 properties

- Porosity

- Flowability

- Collapsibility

- Adhesiveness

- Cohesiveness or strength

- Refractoriness

1. Porosity or Permeability:

It is the ability of sand by which it allows the gases to pass through it easily.

Some gases get dissolved in molten metal and when this molten metal starts to solidify, these dissolved gases come out of the molten metal and try to escape out of the moulding sand. If the sand is not enough porous than these gases will not be able to go out of the mould and gets trapped into the casting and produces holes and pores in metal casting. Also if the molten metal comes in contact with the moist sand, steam or water vapor is produced. This steam or vapors also results in the formation of holes in the casting if they do not able to escape out of the mould. So it is advised to use sufficiently porous moulding sand to eliminate the porosity defect in metal casting.

2. Flowability

The ability of moulding sand to behave like a fluid when it is rammed is called flowability.

Due to this property, the sand can easily occupy the space in molding box and take up its shape. This allows the sand to compress to a compact density and let it pack around the pattern. The sand should be of high flowability, so that it can be easily compacted for uniform density and to obtain a good impression of the pattern in the mould. The flowability of the sand can be increases as we increases the clay and water content in the sand.

Also Read:

- Difference Between Forging vs Casting

- What are the Melting Points of Metals?

- Blast Furnace: Introduction, Definition, Construction, Working Principle, Applications & Advantages

3. Collapsibility

The ability of the moulding sand to collapse after solidification of the molten metal is called collapsibility.

After the solidification of molten metal, the sand should get collapse for free contraction of the metal. If free contraction of the metal will happen than if eliminates naturally the tearing or cracking of the contracting metal.

4. Adhesiveness.

The ability of the sand particles to get stick with another body is called adhesiveness.

The sand should have sufficient adhesiveness so that it can easily get cling to the sides of the moulding boxes and does not fall out to the box when it is removed.

5. Cohesiveness or Strength

The ability of the sand particles to stick with each other is called cohesiveness.

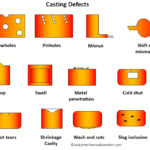

The strength of the sand depends upon how cohesive the sand particles are. The sand should have sufficient strength so that it can easily capable to retain its shape during conveying, turning or closing and pouring. If it is not of appropriate strength than it will not be able to hold its shape and the mould may damage during pouring of molten metal. Low strength sand leads to pouring casting defects in metals. To avoid pouring defects, the sand should be of sufficient strength to produce mold of desired shape and also retain this shaped even when the molten metal is poured in the moulding cavity.

The sand strength can be of two types

(i) Green strength: The strength of sand possessed by it in its green or moist state is called green strength. The mould with adequate green strength retains its shape and do not collapse even when the pattern is removed from the moulding box.

(ii) Dry strength: The strength possessed by the sand in its dry or baked state is called dry strength. Enough dry strength allows the sand to withstand erosive forces due to molten metal and helps to retain its shape.

6. Refractoriness

The ability of the moulding sand to withstand the high temperature of the molten metal without fusing into it is called refractoriness.

The moulding sand must have enough refractoriness property to produce excellent quality of casting free from defects. The sand with lack of refractoriness melts and gets fuse in the casting and spoils the quality of the cast metal. The refractoriness is the measure of sinter point of the sand not its melting point.

This is all about the six properties of moulding sand. Every types of moulding sand used in the casting process must have these six properties. If you find anything missing comment us.

thermal stability:

The sand adjacent to the metal is suddenly heated and undergoes expasin.if the mould wall is not dimensionally stable under rapid heating,cracking,bucking and flacking off sand may occur.