For the air intake in the engine, there are two procedures, one is a natural aspiration and another is a forced aspiration. Naturally aspirated engines take the air from the outside environment through the intake manifold from the air filter. This kind of engine was used in earlier days but nowadays almost every engine is equipped with a mechanical device for force air intake which helps the engine at the inlet valve to compress the air from the air filter. This is collectively called a turbocharger.

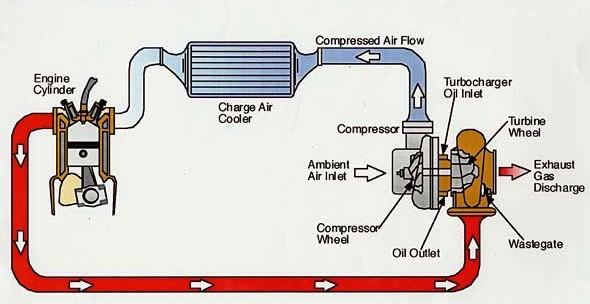

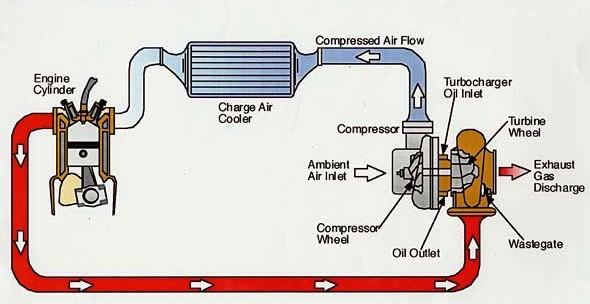

A turbocharger is powered by exhaust gases from the engine, which means turbocharger gets power from exhaust gases whereas all superchargers get power from a pulley or engine belt. It is used for regaining energy from waste gases at the exhaust. It increases the power output by compressing more air into the cylinder.

Main Parts of Turbocharger

It consists of two housings:

- Exhaust housing and

- Compressor housing

Exhaust Housing

It has a turbine wheel, and when Exhaust gases directly strike the turbine, It starts rotating because heat energy is converted into kinetic energy. The turbine wheel is connected with a compressor of the same shaft so the compressor also starts rotating automatically. Exhaust housing is made up of special material (NI RESIST) to resist high temperatures of exhaust gases (temperature around 900°-1000°Celsius).

Compressor Housing

It has the compressor wheel, this will get rotation from the turbine wheel and the compressor sucks the air from the outside environment. It means less pressurized air converted into high pressurized air due to compressor. Compressor wheel made up of INCONEL.

Middle Portion of Turbocharger:

Between Turbine and Compressor Housing, Shaft is the only way of connecting both wheels. This shaft made up of pure steel. Shaft only takes rotation with either bush or bearing. In turbocharger bearing construction is complex compared to bush, so bushes are having the oil seals at both ends on shaft. Bushes and shaft both are made up of metal, so friction is more, to reduce the friction between them move oils (Turbo oil) are added in the device. To stop the oil leak of move oil (Turbo oil) oil seals are fixed at in front of bushes.

Also Read:

- Difference Between Turbocharger and Supercharger

- Comparison Between Roots, Twin Screw and Centrifugal Supercharger

- What is Air Compressor and its Types?

Working of Turbocharger

- Turbocharger can start its process at high RPM around 1000-1200 rpm. This is because the engine produces more exhaust smoke at high rpm; so that it can able to rotate the turbine wheel. With low rpm, it doesn’t have that much of rotational force that is required to turn the turbine wheel.

- A turbocharger is suitable for multi-cylinder engines because a single-cylinder engine cannot produce as much exhaust gas as the Multi-cylinder engines.

- The compressor wheel gets its rotation from the turbine wheel, thus compressor wheel gets starts sucking air from the air filter through the outside. The main work of the compressor wheel is to send pressurized air into the intercooler. We may actually send air from the compressor to directly at intake manifold after the compressor wheel. But air after the air filter has temperature around 45° Celsius which depends upon the outside atmosphere and due to compressor, this air temperature increased up to 200° Celsius.

- We know that the air density of high temperature is less as compared to cold air. That’s why to cool down the air; an intercooler plays a major role in turbochargers. Air density of less temperature air is high which means more air molecules mean more oxygen to burn fuel for the high explosion in the combustion chamber. So, an intercooler decreases air temperature for more air molecules.

For a better explanation of how a turbocharger works watch the video given below:

Turbocharger Limit

It has a maximum rpm of 2.5 Lakh-3 Lakh/minute, by crossing its limit an imbalance is created at the shaft that breaks the oil seals and it can cause engine damage. To prevent this issue turbocharger is equipped with valve between two housing. At a particular high pressure, means pressure produced after 3 lakh rpm/min valve can automatically open up and it can divert the extra exhaust gas towards the silencer rather than the turbine wheel so that it can stop the crossing the limit of 3 lakh rpm/minute automatically.

Also Read:

- How Anti-lock Braking System (ABS) Works – Explained

- History of Automobile – How Modern Automobile Evolved?

- Centrifugal Supercharger – Working Principle, Main Parts, Advantages, Disadvantages with Application

A turbocharger actually forces the air into the cylinder, so by forcing additional air which is called a boost. More air means more oxygen and can burn more fuel which can create a greater explosion compare to normal combustion in the cylinder. The piston moves very rapidly as compared to normal piston movement in normal engines. Without a turbocharger, it does not create this fast reciprocating motion in the engine. At high reciprocating motion, piston force is high that can provide crankshaft greater turn. In a transmission system, engine crankshaft converts the reciprocating motion of the piston into rotary motion then this motion drives the flywheel and driveshaft respectively. If this entire process runs at higher rotation, so it can produce more speed at vehicle differential. Effectively by increasing the explosion inside the cylinder gives greater rotational force at wheels.

Advantages:

- A decrease in Emission.

- Increase in Horsepower.

- Does not require an external power source to run a turbocharger

Disadvantages:

- Turbo lag is the time between the demand for an increase in power and the turbocharger providing increased intake pressure, and hence increased power. Turbo lag occurs because turbochargers rely on the buildup of exhaust gas pressure to drive the turbine. In simple words, the turbocharger is turned on after a particular amount of exhaust gas is produced which happens at a certain rpm. So when this threshold rpm is crossed the turbo does not instantly delivery requisite power surge or boost, and during this period the vehicle does not move very fast when the throttle is given or accelerated. This is due to the time needed for the exhaust system and turbocharger to generate the required boost. Load on the compressor, friction, and inertia are the main contributor for turbo lag.

- The space requirement is more.

Conclusion

In this article, we have learned about how a turbocharger works in an internal combustion engine. If you really like the information share here then don’t forget to like and share it.