In this article we will study about the Pelton wheel or Pelton turbine working, main parts, application with diagram. It is a hydraulic turbine which is used in most of the hydroelectric power plant to generate electricity. It is used for the water available at high head.

What is Pelton Turbine?

It is a type of tangential flow impulse turbine used to generate electricity in the hydroelectric power plant. This turbine was discovered by the American engineer L.A. Pelton.

- The energy available at the inlet of the Pelton turbine is only kinetic energy. The pressure at the inlet and outlet of the turbine is atmospheric pressure.

- This type of turbine is used for the high head.

Main Parts

The various parts of the Pelton turbine are

|

| Pelton Turbine |

1. Nozzle and Flow Regulating Arrangement (Spear)

- Nozzle is used to increase the kinetic energy of the water that is going to strike the buckets or vanes attached to the runner.

- The quantity of water that strikes the buckets is controlled by spear. The spear is installed inside the nozzle and regulates the flow of water that is going to strike on the vanes of the runner. A nozzle containing spear is shown in the figure given below.

- The spear is a conical needle present in the nozzle. It is operated by a hand wheel or automatically in an axial direction.

- When the spear is move backward the rate of flow of water increases and when it is pushed forward the rate of flow of water decreases.

Also Read:

- What is Kaplan Turbine and How It Works?

- Francis Turbine Working Principle, Main Parts, Diagram and Application

- What is Reaction Turbine – Principle, Working, Main Components and Application

2. Runner and Buckets

The runner with buckets is shown in the figure given below.

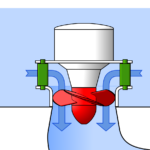

- Runner is a rotating part of the turbine. It is a circular disc on the periphery of which a number of buckets evenly spaced are fixed.

- The buckets are made by two hemispherical bowls joined together. Each bucket has a wall in between two hemispherical bowl called splitter.

- The splitter splits the jet of water striking the buckets into two equal parts and the jet of water comes out at the outer edge of the bucket.

- The buckets are designed in such a way that the jet of water strikes the buckets, deflected through 160 degree to 170 degree.

- The buckets of the Pelton turbine are made up of cast iron, cast steel bronze or stainless steel.

3. Casing:

The outer covering of this turbine is called casing. The Pelton turbine with the casing is shown in the figure given below.

- It prevents the splashing of the water and helps to discharge the water to the trail race. It also acts as a safeguard in the case of an accident occurs.

- Cast iron or fabricated steel plates are used to make the casing of the Pelton Turbine.

4. Breaking jet

- When the jet of water is completely closed by pushing the spear in the forward direction than the amount of water striking the runner becomes zero. But still, the runner keeps moving due to the inertia of the runner.

- In order to stop the runner in the shortest possible time, a small nozzle is provided which directs the jet of water at the back of the vanes. This jet of water used to stop the runner of the turbine is called breaking jet.

Working of Pelton Trubine

- The water stored at a high head is made to flow through the penstock and reaches the nozzle of the Pelton turbine.

- The nozzle increases the K.E. of the water and directs the water in the form of a jet.

- The jet of water from the nozzle strikes the buckets (vanes) of the runner. This made the runner rotate at a very high speed.

- The quantity of water striking the vanes or buckets is controlled by the spear present inside the nozzle.

- The generator is attached to the shaft of the runner which converts the mechanical energy ( i.e. rotational energy) of the runner into electrical energy.

Application

This is all about the Pelton turbine working, main parts, application with diagram. And if you like the article then don’t forget to like and share it.