Welding is one of the most progressive trades of the 21st century. Working with metal is one of the best careers that you can choose if you love working with your hands. However, before you get into the venture, you should know several important things. This is a very demanding job, so the first thing you should know is everything regarding the job. Thankfully, you will find all the information that you need online.

Here are a few things you should know to become a welder:

What Education is Needed?

This depends on the employer who will give you a job. Some of them may ask you to take an employer test to see what skills you have, on top of formal training. Others may also ask for a technical training certificate from a local university, mostly associate degree from a community college or a vocational training institute.

It is best to check the requirements before you can apply for a job so that you can see what is required. Before you undertake this training to become a welder, find out what most employers look for and go with that.

Types of Welding Careers

Welding career does not only mean being the hands-on welder. There are many more things that you can be, if you choose. One of them is to become a welding inspector. Your work in such a position would be to inspect the quality of the welds.

You can also become a welding educator and work in the community college. As you gain more education and expertise, you will find that more opportunities come up. There is no limitation, you can become just about anything that you like.

Also Read:

- What is Soldering and How it Works?

- What is Brazing and How Does it Work?

- What is Powder Metallurgy – A Modern Manufacturing Process

You Will Require Certification

Welding is a very important craft for moving the world forward. It is used in aircraft manufacture, shipbuilding and other fields. That is why there is the American Welding Society, which is responsible for giving certification. To get this certification, you will require to take a test in a center that has been approved by the AWS, or the employer may allow you to take a test of their own to determine your skills.

Work Conditions

Welding work conditions vary from place to place. It is just like any other workplace although there may be more hazards in a welding workshop than you would find in a place like a classroom.

Payment is good. Back in 2015, the average wage for welders was about $19.50 per hour. Typically, a welder will work about 40 hours a week in a factory floor, fabrication center, a workshop, shipyard or wherever else his or her services may be needed.

You can also become a welder for your own home improvement jobs. Just make sure you gear up properly all the time. You need something to wear for protecting your feet, your hands, your eyes, and every other exposed part.

Different Welding Jobs Require Different Welding Techniques

There are different types of welding techniques to apply for various jobs. Here is a sneak peek into them:

Stick welding –

This one is the simplest of the welding jobs. You use a stick rod that is about a foot long, and replace it when it is depleted. This type of welding is best for light-duty jobs. You can use it for home improvement welding jobs and others.

Mig welding –

Also called metal inert gas welding, this one is mostly used for stainless steel, steel, aluminum, and others. It is mostly used for fabrication in shipyards and large industries.

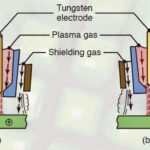

TIG welding –

This one is used for jobs that need high quality welding. It can also be used for stainless steel welding. While MIG and stick welding do not require very strict training, TIG welding does.

Common Sense Things to Do When You are a Welder

Apart from going for training, you will also need to do learn a few other common sense skills. Here are the things that you should do:

- You should be very organized. You should never work in a cluttered workshop as it poses many hazards.

- Always take good care of your gear because you are as good as your gear.

- You need a proper hand and eye coordination. These are the two parts of the body that are used most in welding

- Always wear protective gear – A helmet for your head and eyes, gloves for your hands and many more.

In this post, we have discussed how to become a welder and start your career as a welder in the welding industry. If you found this interesting and useful then don’t forget to share and like.