What is Brazing and How Does it Work?

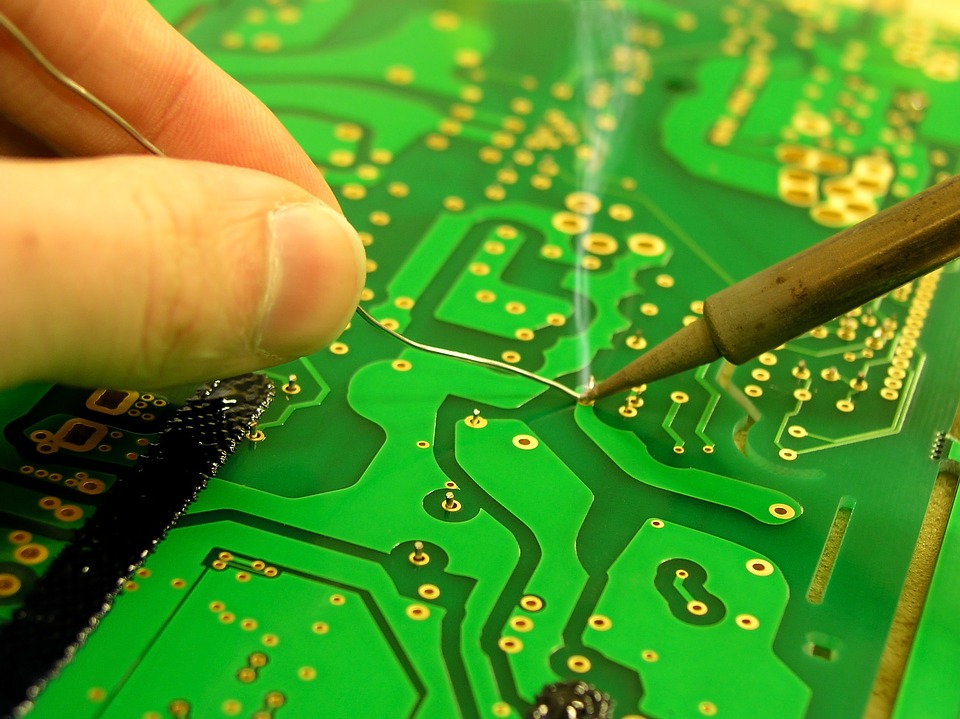

What is Brazing? Basically, brazing, welding, soldering all are quite similar metal joining processes. There are some little bit differences which compel us to give different names to this metal joining processes. In this article we will discuss what is brazing, why brazing is different from soldering and welding, why to select brazing and not […]