Walk into any parts store or scroll through a few ecommerce pages and you’ll find hundreds of car-lift models—each one promising unbeatable capacity, whisper-quiet hydraulics, or “professional-grade” steel.

For first-time buyers running a micro-shop or outfitting a home garage, those claims blur together fast. Do you prioritize ALI certification, ceiling height, motor voltage, or pure sticker price?

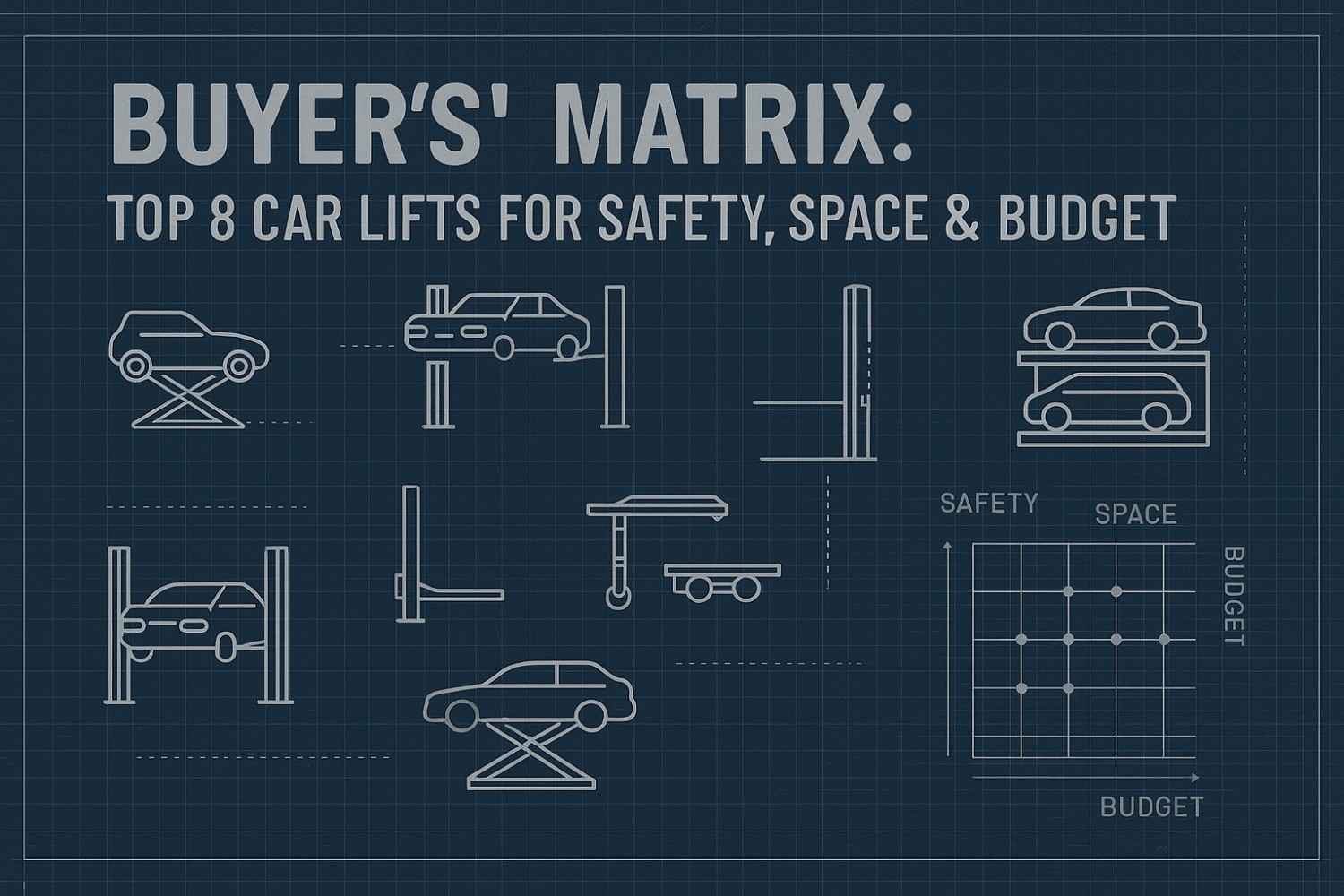

This guide cuts through the clutter. Instead of another random “top ten” list, we built a Buyer’s Matrix that scores popular lift categories on four critical axes: Safety, Space Efficiency, Install Complexity, and Budget/ROI.

Paired with narrative reviews of eight standout lift types, the matrix lets you match a lift to your exact bay dimensions, vehicle mix, and growth plans in minutes—no spreadsheet required.

Why Build a Buyer’s Matrix?

Car-lift shopping is a classic case of decision fatigue. You’re weighing:

- Ceiling height vs. maximum rise.

- Vehicle mix (Miata vs. ¾-ton pickup) vs. weight capacity.

- Electrical supply vs. motor horsepower.

- Concrete PSI vs. anchor-bolt length.

Give each lift type a 1–5 score for the criteria you care about, total the numbers, and your short-list reveals itself. Better yet, you can re-weight the axes when priorities shift—say, when you move from a rented 9-foot bay to a purpose-built 14-foot shop.

The Safety Baseline: Certifications & Standards

Safety isn’t just a feel-good talking point; it’s the thin line between predictable uptime and a six-figure liability claim.

In North America, the gold standard is the ALI Gold Label issued under ANSI/ALI ALCTV. That label confirms the lift survived independent stress tests, overload trials, and control-system inspections.

The Automotive Lift Institute (ALI) keeps technicians up-to-date, too. In May 2025, it released an all-new Vehicle Lifting Points Guide covering model years 2000–2025 with both print and digital search options.

Two years earlier, it expanded its classic Lifting It Right safety manual into a 36-page second edition with fresh photos and a digital version.

Weight Capacity: Myth vs. Reality

Modern engineering lets two-post lifts handle 18,000 lb with ease—provided operators use certified gear and proper adapter points.

A quick sizing rule: Choose a lift rated for your heaviest vehicle plus 20 percent headroom so you’re never tempted to flirt with the limit.

Buyer’s Matrix

Scoring key: 1 = poor, 5 = excellent. Total possible = 20.

- Portable Low-Rise Scissor — Safety 3, Space 5, Install 5, Budget 5

- Two-Post Symmetric — Safety 4, Space 3, Install 3, Budget 4

- Two-Post Asymmetric — Safety 4, Space 3, Install 3, Budget 4

- Four-Post Storage/Service — Safety 4, Space 2, Install 3, Budget 3

- Alignment Runway — Safety 5, Space 2, Install 2, Budget 2

- Mobile Column Set — Safety 4, Space 4, Install 4, Budget 2

- EV Battery Table — Safety 5, Space 4, Install 3, Budget 3

- Parking Stacker — Safety 3, Space 5 (vertical), Install 2, Budget 2

How to use it: Circle the axis that matters most. Limited ceiling? Sort by Space 5s. Tight cash flow? Start with Budget 5s. The highest composite score isn’t “best”; it’s “best for your constraint.”

The 8 Car Lifts You Should Compare in 2026

1. Wrenchers Portable Low-Rise Scissor Lift

Short on square footage? QuickJack series units roll out like a floor jack, elevate the chassis 24–26 inches, and disappear upright against a wall when the job’s done.

Many models plug into a standard 110–120 V outlet and only need a 4-inch, 3,000-psi slab. Capacity hovers near 6,000–8,000 lb—plenty for sedans, crossovers, and light pickups.

The trade-off is limited under-vehicle access; exhaust or transmission swaps still demand jack-stands.

For budget DIYers or mobile detailers, though, the convenience is unbeatable. Check the portable-lift lineup at Wrenchers, where every order ships free and several models feature quick-connect hydraulic lines for fast setup..

2. Two-Post Symmetric Lift

The symmetric design keeps each arm the same length, centering the vehicle’s centre of gravity between posts. That square stance is ideal for vans, trucks, and anything with a heavy rear differential.

Expect 10,000–12,000 lb standard capacity and up to 18,000 lb on heavy-duty models. You’ll need 12 feet of clear ceiling and a dedicated 220 V / 30 A circuit. Anchor bolts must bite into at least 4 inches of 3,500-psi concrete.

Pay attention to arm-restraint locks and automatic shut-off at full height—features normally found on ALI Gold-Label lifts from brands like BendPak and Challenger.

3. Two-Post Asymmetric Lift

Rotate each column 30 degrees and shorten the front arms, and you get the asymmetric layout—perfect for modern coupes and sedans whose doors need space to swing open.

Weight still centers between the posts, but the front wheels sit a bit forward, giving technicians room to slip into the cabin for scan-tool hookups or steering-wheel locks.

Installation mirrors the symmetric cousin (same power, same slab), yet drive-through width shrinks a hair. Mixed-fleet garages often keep one asymmetric bay for daily drivers and one symmetric bay for trucks.

4. Four-Post Storage/Service Lift

Four columns, full runways, zero anchor bolts. Drive on, hit the button, and a mechanical latch engages every six inches. Because the vehicle rests on its tires, newbie operators love the margin for error; there’s no hunting for frame points.

Add a pair of hydraulic bridge jacks and you can still lift the wheels clear for brakes. For homeowners, the real perk is vertical storage: raise the classic Mustang, park the daily cruiser below, and reclaim 200 sq ft of floor.

Downsides? A 185-inch runway demands a deep bay, and the lift weighs twice a two-post, complicating freight.

5. Alignment Runway Lift

Think of this as a four-post on steroids. Flush-mount turnplates and rear slip plates let alignment heads measure camber and toe while the suspension sits at ride height. Built-in air lines power rolling jacks, so wheels come off without losing the alignment plane.

Capacities start at 12,000 lb; 14,000–18,000 lb is common. You’ll need a 20-foot bay length and a level floor within 1/8-inch, or the heads won’t zero out.

6. Mobile Column Lift Set

Imagine four to eight battery-powered columns, each rated at 18,000 lb, that sync via wireless controls. Roll them to the chassis, clamp onto the wheels or frame yokes, and lift an entire bus in 90 seconds.

Because the columns store upright, they free the floor for other work when not in use. They’re also the priciest option here—often topping six figures for a full eight-column package—and require a virtually flawless concrete surface.

Fleet operators love them for diesel service bays; small shops can start with four columns and expand later.

7. EV Battery Table Lift

Battery packs in modern BEVs weigh 1,000–2,500 lb and extend across the wheelbase. Dropping one safely demands a low-rise table with synchronized scissor actuators, side-shift rollers, and 360-degree caster wheels.

Typical rise is 24–30 inches—high enough to meet the chassis, low enough to keep the centre of gravity stable. Some models double as power-train tables for engine swaps. Expect integrated 110 V chargers and pendant controls.

As EV market share climbs, an EV table is becoming as essential as a tire changer.

8. Parking Stacker Lift

When real estate costs more per square foot than steel, go vertical. A parking stacker lifts one vehicle roughly 85–90 inches, locking it on mechanical safeties so another car can park beneath.

Most units run on a quiet 110 V power pack and use a single hydraulic ram with steel cables. Set up demands only four anchors, but does require a perfectly level slab.

Homeowner associations like the low noise signature, making stackers a favorite for collectors squeezed into suburban garages. Add drip trays to keep the top car’s fluids off the convertible below.

Pre-Purchase Checklist

- Concrete: Verify thickness and PSI with a core sample; most two-post lifts need 4 in @ 3,500 psi.

- Clearance: Measure ceiling height and add six inches for the highest vehicle’s roof.

- Power: Confirm 110 V vs. 220 V and breaker size; separate circuits reduce nuisance trips.

- Permits & Insurance: Some municipalities treat lifts as “elevating devices.” Inform your insurer early.

- For alignment bays: Review the role of tread patterns in tire performance so you can upsell a rotation while wheels are off.

Future-Proofing: Market Growth & EV Trends

Analysts forecast the global lift market to climb from USD 3.2 billion in 2025 to USD 4.9 billion by 2035, a 4.4% CAGR—driven by rising vehicle ownership and the need for efficient maintenance bays.

Heavier EV curb weights are a big part of that growth; a Ford F-150 Lightning tips the scales north of 6,500 lb. That means higher capacities, reinforced swing arms, and specialty battery tables will soon be the norm.

ALI is already keeping pace: its 2024 digital Lifting Points Guide aggregates two decades of OEM data for quick lookup.

Conclusion

Choosing a car lift isn’t about the shiniest paint or deepest discount. Start with Safety, double-check Space, and run the numbers on Budget—all captured in the Buyer’s Matrix above.

Copy the matrix into your own notebook, adjust the scores to match your constraints, and let the numbers steer the purchase. When your lift locks into its first safety notch with zero drama, you’ll be glad you let the math—and not the marketing—make the call.