Introduction

“An object remains in its state of rest or in motion until and unless acted upon by an external force” Newton’s first law of motion, this law by Sir Isaac Newton gave rise to the development of braking system in an automobile, developing an automobile vehicle not only requires the power source but also the efficient braking system as higher the horse power higher will be the brake force required to stop or de accelerate that vehicle. This thought gave rise to many researches in the field of braking and results in its evolution due to which today we have flexibility in choosing a suitable braking system according to our need.

We spoke to an automobile expert who works hand in hand with van leasing companies, he said, ” Brakes are perhaps the most important safety feature of any vehicle. Knowing the different types of brakes, both between and within vehicles can help you feel better informed when caring for and repairing brakes.

So let’s just start our article with the curiosity about the various types of braking systems.

In an automobile vehicle, a braking system is an arrangement of various linkages and components (brake lines or mechanical linkages, brake drum or brake disc , master cylinder or fulcrums etc) that are arranged in such a fashion that it converts the vehicle’s kinetic energy into the heat energy which in turn stops or de accelerate the vehicle.

The conversion of kinetic energy into heat energy is a function of frictional force generated by the frictional contact between brake shoes and moving drum or disc of a braking system.

Need of a Braking System

In an automobile vehicle braking system is needed –

- To stop the moving vehicle.

- To de accelerate the moving vehicle.

- For stable parking of a vehicle either on a flat surface or on a slope.

- As a precaution for accidents.

- To prevent the vehicle from any damage due to road conditions.

Classification of Braking System

As we have already discussed the evolution of braking system from vintage carts to modern cars, from vintage carriages to modern trucks has given us various different purpose braking systems which are classified on the basis of various needs and purposes of an automobile vehicle. so let’s just discuss them-

1. On the Basis of Power Source

The power source which carries the pedal force applied by the driver on brake pedal to the final brake drum or brake disc in order to de accelerate or stop the vehicle the braking systems are of 6 types-

- Mechanical braking system

- Hydraulic braking system

- Air or pneumatic braking system

- Vacuum braking system

- Magnetic braking system

- Electric braking system

2. On the Basis of Frictional Braking Contact

On the basis of the final friction contact made between the rotating brake components i.e. brake drum or disc rotor and the brake shoe the braking systems are of 2 types-

(i) Internal expanding brakes (e.g.- drum brakes)

(ii) External contracting brakes(e.g. disc brakes)

3. On the Basis of Application-

On the basis of method of applying brakes, braking systems are of 2 types-

- Foot or Service Brakes

- Hand or Parking Brakes

4. On the Basis of Brake Force Distribution

- Single Acting Brakes

- Dual Acting Brakes

Also Read:

- What is Brake Booster and How it Works?

- Anti-lock Braking System (ABS) – Working Principle, Main Components with Advantages and Disadvantages

- Drum Brakes vs Disc Brakes – Which is Better?

Detailed Description of Different Types of Braking Systems

On Power Source Basis

1. Mechanical Brakes:

It is the type of braking system in which the brake force applied by the driver on the brake pedal is transferred to the final brake drum or disc rotor through the various mechanical linkages like cylindrical rods, fulcrums, springs etc. In order to de accelerate or stop the vehicle.

- Mechanical brakes were used in various old automobile vehicles but they are obsolete now days due to their less effectiveness.

2. Hydraulic Brakes:

It is the type of braking system in which the brake force applied by the driver on brake pedal is first converted into hydraulic pressure by master cylinder (for reference read article on master cylinder) than this hydraulic pressure from master cylinder is transferred to the final brake drum or disc rotor through brake lines.

- Instead of mechanical linkages, brake fluid is used in hydraulic brakes for the transmission of brake pedal force in order to stop or de accelerates the vehicle.

- Almost all the bikes and cars on the road today are equipped with the hydraulic braking system due to it high effectiveness and high brake force generating capability.

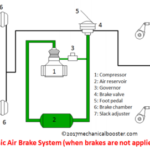

3. Air or Pneumatic Brakes:

It is the types of braking system in which atmospheric air through compressors and valves is used to transmit brake pedal force from brake pedal to the final drum or disc rotor.

- Air brakes are mainly used in heavy vehicles like busses and trucks because hydraulic brakes fails to transmit high brake force through greater distance and also pneumatic brakes generates higher brake force than hydraulic brake which is the need of the heavy vehicle.

- The chances of brake failure is less in case of pneumatic brakes as they are usually equipped with a reserve air tank which comes in action when there is a brake failure due to leakage in brake lines.

- High end cars these days are using air brakes system due to its effectiveness and fail proof ability.

4. Vacuum Brakes:

It is the conventional type of braking system in which the vacuum inside the brake lines causes brake pads to move which in turn finally stops or de accelerates the vehicle.

- The exhauster, main cylinder, brake lines, valves along with disc rotor or drum are the main components that combine together to make a vacuum braking system

- Vacuum brakes were used in old or conventional trains and are replaced with air brakes nowadays because of their less effectiveness and slow braking.

- Vacuum brakes are cheaper than air brakes but are less safe than air brakes.

5. Magnetic Brakes:

In this types of braking system, the magnetic field generated by permanent magnets is used to cause the braking of the vehicle.

- It works on the principle that when we pass a magnet through a cooper tube, eddy current is generated and the magnetic field generated by this eddy current provide magnetic braking.

- This is the friction less braking system thus there is less or no wear and tear.

- This is the advanced technology in which no pressure is needed to cause braking.

- The response to the braking in this is quite quick as compared to other braking systems.

6. Electrical Brakes:

It is type of braking used in electric vehicle in which braking is produced using the electrical motors which is the main source of power in electric vehicles, it is further divided into 3 types-

(i) Plugging Brakes-When the brake pedal is pressed in the electric vehicle equipped with plugging braking, the polarity of the motors changes which in turn reverses the direction of the motor and causes the braking.

(ii) Regenerative Braking- It is the type of electrical braking in which at the time of braking the motor which is the main power source of the vehicle becomes the generator i.e. when brakes are applied, the power supply to the motor cuts off due to which the mechanical energy from the wheels becomes the rotating force for the motor which in turn converts this mechanical energy into the electric energy which is further stored in the battery.

- Regenerative braking saves the energy and are widely used in today’s electric vehicles.

- Tesla Model-S provides the most effective regenerative braking.

(iii) Dynamic or Rheostat Braking- It is the type of electrical braking in which resistance provided by the rheostat causes the actual braking, in this type a rheostat is attached to the circuit that provides the resistance to the motor which is responsible for de acceleration or stopping of the vehicle.

Also Read:

- How Suspension System Works in Automobile?

- Manual Vs Automatic Transmission

- Types of Gearbox – Complete Explanation

On Frictional Contact Basis

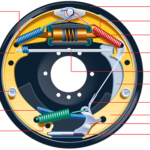

1. Drum Brakes or Internal Expanding Brakes

It is the type of brake system in which a drum which is the housing of the brake shoes along with actuation mechanism is attached with the wheel hub in such a fashion that the outer part of the drum rotates with the wheel and inner part remains constant.

When brakes are applied the actuating mechanism (wheel cylinder or mechanical linkage.) causes the brake shoes to expand due to which the outer frictional surface of the brake shoes makes frictional contact with the rotating drum part which in turn stops or de accelerate the vehicle.

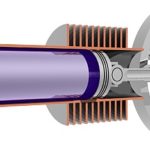

2. Disc Brake or External Contracting Brakes –

It is the types of braking system in which instead of a drum assembly a disc rotor attached to the hub of the wheel in such a fashion that it rotates with the wheel, this disc rotor is clamped in between the caliper which is rigidly fixed with the knuckle or upright of the vehicle.

- This caliper used is the housing of the brake shoes along with the actuation mechanism (mechanical linkages or caliper cylinder).

- When the brakes are applied the actuation mechanism contracts the attached brake shoes which in turn makes the frictional contact with the rotating disc rotor and causes the braking of the vehicle.

On Application Basis

1. Service Brake or Foot Brakes-

It is the type of brakes in which the brakes are applied when the driver presses the brake pedal mounted inside the cockpit or at the foot space of the vehicle with his foot, this pedal force applied by the driver is further multiplied and sent to the braking drum or disc either by mechanical linkages or by hydraulic pressure which in turn causes braking.

- In cars foot operated brakes are used and in bikes the combination of foot and hand operated brakes are used.

2. Hand Brake or Parking Brake–

This type of brakes are also known as emergency brake as they are independent of the main service brake, hand brakes consists of a hand operated brake lever which is connected to the brake drum or disc rotor through the metallic cable.

- When hand brake lever is pulled, tension is created in the metallic rod which in turn actuates the brake drum or disc rotor mechanism and final braking occurs.

- Hand brakes are usually used for stable parking of the vehicle either on flat road or slope that is why it is also called parking brakes.

Also Read:

- Torque Converter Working, Principle, Main Parts and Application.

- History of Automobile – How Modern Automobile Evolved?

- How DTSi Engine Works – Explained?

On Brake Force Distribution Basis

1. Single Acting Brakes:

It is the type of braking in which brake force is transferred to either a pair of wheels(in cars) or to the single wheel(in bikes) through single actuation mechanism(mechanical linkages or master cylinder).

- These types of braking system is commonly used in bikes or in light purpose vehicles.

2. Dual Acting Brakes:

It is the type of braking in which the brake force is transferred to all the wheels of the vehicle through dual actuation mechanism (tandem master cylinder or mechanical linkages).

- This type of braking is used in cars as well as in heavy purpose vehicle.

Application of Different Types of Braking

- Mechanical brakes- Cars like Ford Model Y and bikes like Bajaj pulsar 180cc.

- Hydraulic brakes- Modern cars like Maruti Suzuki swift and bikes like KTM Duke 390.

- Air brakes – Volvo buses and various heavy vehicles

- Vacuum brakes- old trains

- Magnetic brakes- Bugati veyron and various hyper cars.

- Electric braking- Tesla Model S Use regenerative type electric braking.

- Drum brake- Old Maruti 800 and Tata 407

- Disc brake- All modern cars like Hyundai i20.

- Hand brake and foot brake– All automobile vehicles.

- Single acting – TVS Appache 180 front disc.

- Dual acting- All 4 wheel cars and trucks.

Conclusion

In this post, we have studied about Types of Braking System in automobile. The braking system is very important do control your vehicle when it is running on roads. Without brakes you can’t stop your cars, bikes, etc. I hope you have understood about braking types clearly. If you enjoyed the information then don’t forget to like and share it.